Method for ananas leaf harvesting and fiber extracting by adoption of combined harvester

A combine harvester and fiber extraction technology, which is applied in the fields of harvester, fiber processing, fiber mechanical separation, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing production cost, reducing labor intensity and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, further illustrate the present invention.

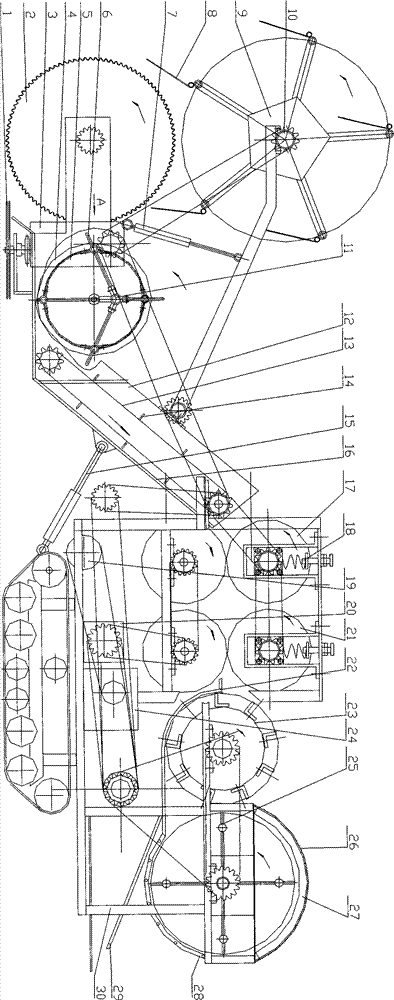

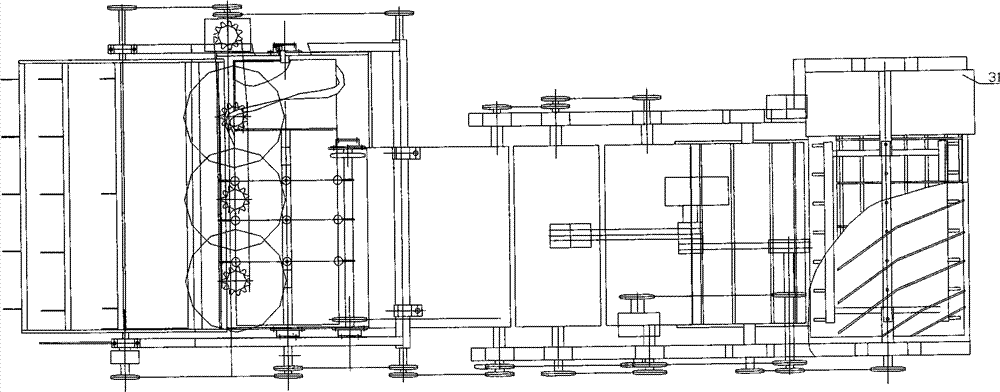

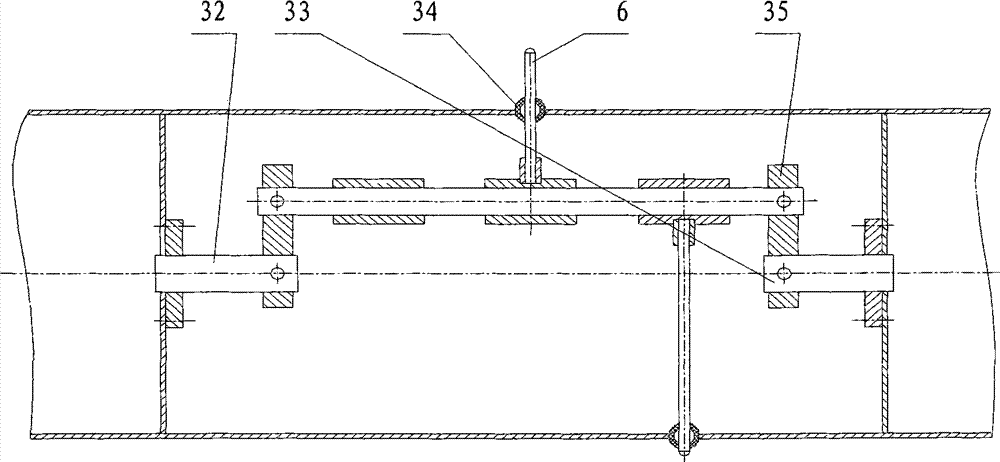

[0019] pass Figure 1-3 As can be seen, a method for pineapple leaf harvesting and fiber extraction using a combine harvester, said combine harvester comprising a harvesting mechanism, a conveying mechanism, a hemp feeding mechanism, a hemp scraping mechanism and a separation device, is characterized in that:

[0020] The harvesting mechanism is used for harvesting pineapple leaves. The harvesting mechanism is connected with the hemp feeding mechanism through a conveying mechanism. A hemp scraping mechanism is arranged behind the hemp feeding mechanism. The machine also has crawler belts, self-propelled device (19) and diesel engine (24), on the one hand said diesel engine (24) provides kinetic energy to crawler belt by self-propelled device (19), on the other hand said diesel engine (24) drives chain through conveyor belt The wheel (10) makes the above mechanism work.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com