Small grain drying machine capable of being used in both continuous mode and cycling mode

A kind of grain dryer, small-scale technology, applied in the direction of dryer, drying, drying solid materials, etc., can solve the problems of low production efficiency, inconvenient batch cycle drying, etc., achieve easy operation, improve flexibility and Convenience and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

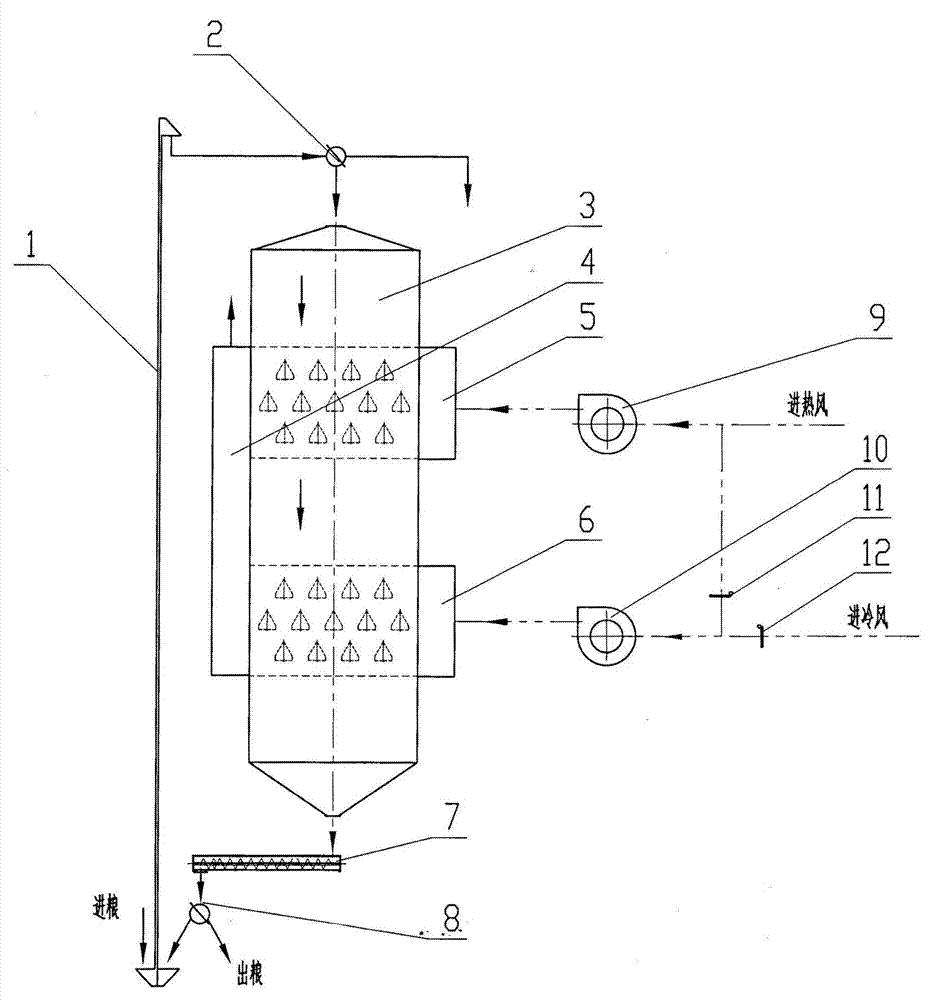

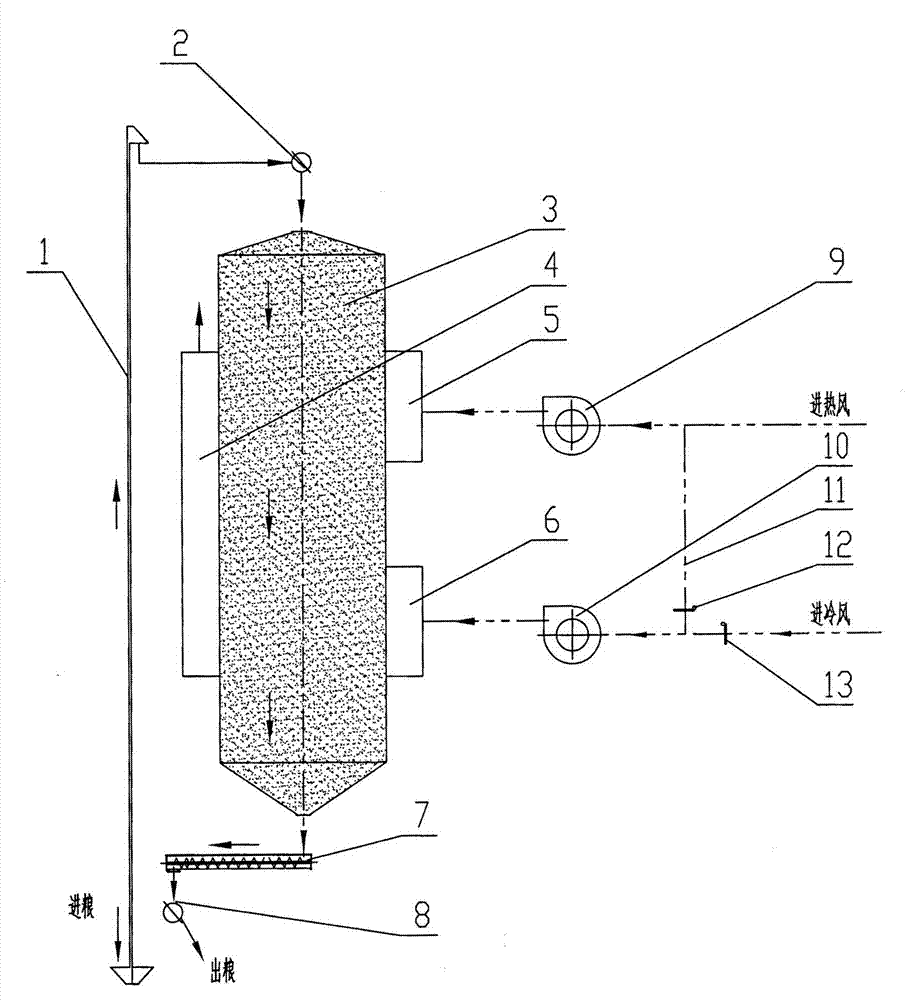

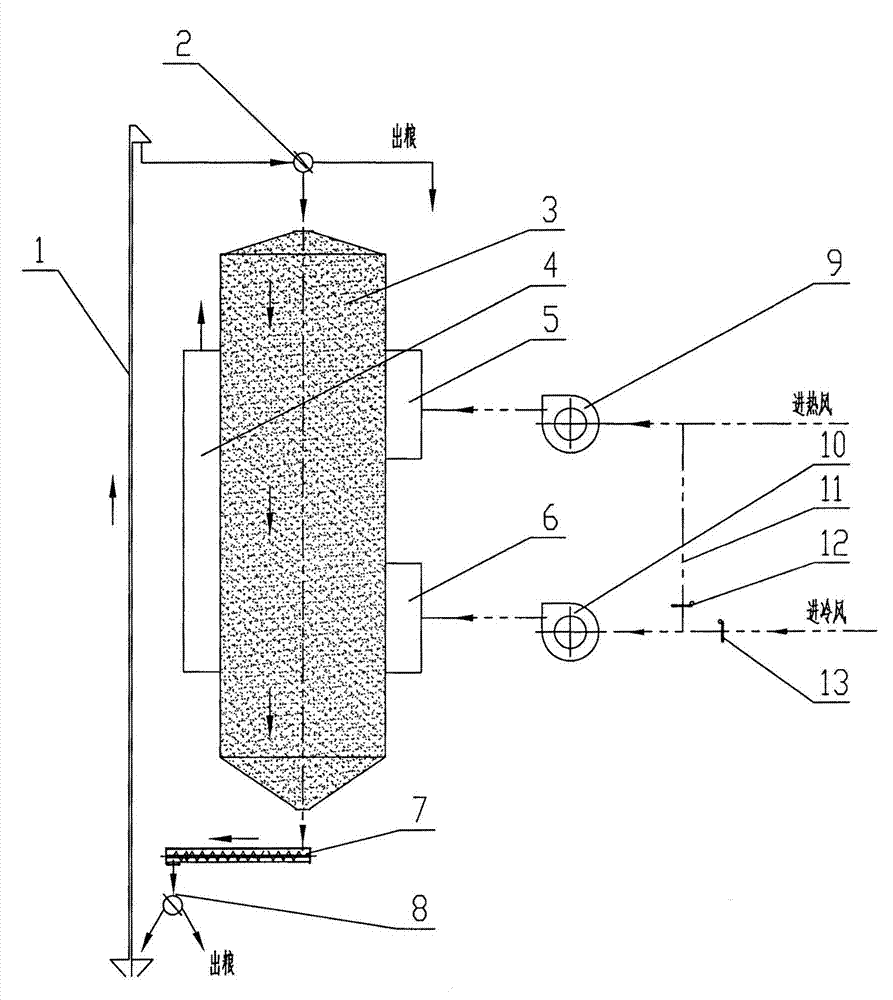

[0016] like figure 1 As shown, the continuous and circular dual-purpose small-scale grain dryer of the present invention comprises a drying tower 3 with a vertical cylinder structure provided with a feed inlet at the top and a discharge outlet at the bottom. The exhaust air duct 4 of the dryer connected to the atmosphere, the upper air intake duct 5 connected to the hot air fan 9 located in the upper middle part of the drying tower, and the lower air intake duct connected to the hot and cold air fan 10 located in the middle and lower part of the drying tower Road 6; the air inlet of the hot air fan 9 is connected to the hot air source through the air duct system 11, and the air inlet of the hot and cold air fan 10 passes through the air duct system 11 and the hot air gate 12 arranged between the air duct system 11 pipelines , cold air gate 13 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com