Multi-station high-pressure water cutting device with position detecting function

A cutting device and high-pressure water technology, applied in the direction of metal processing, etc., can solve the problem of not being able to cut large quantities of non-plate and complex surface workpieces, and achieve the effects of improving cutting efficiency, narrow cutting kerf, and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

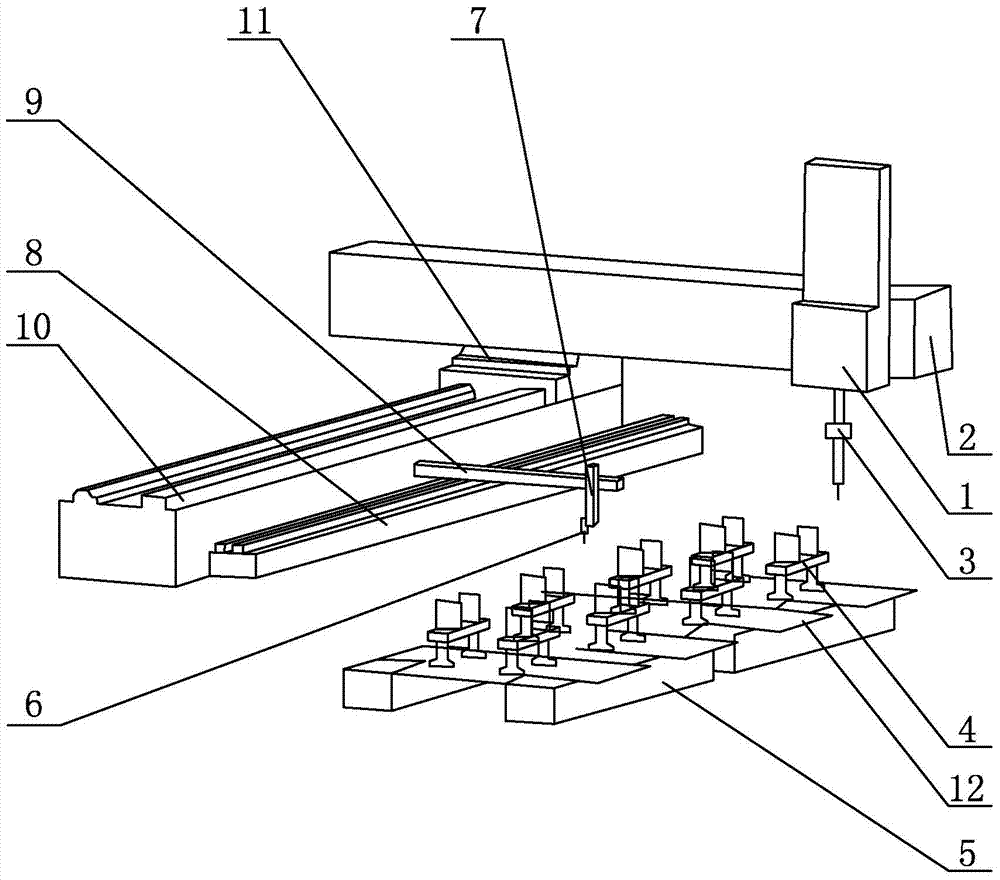

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment. A multi-station high-pressure water cutting device with position detection function described in this embodiment includes a cutting mechanism, a detection mechanism, a detection mechanism slide rail 8, a detection mechanism base 9, a cutting mechanism slide rail 10, a cutting mechanism Base 11 and positioning clamp assembly, detection mechanism slide rail 8, detection, detection mechanism slide rail 8 and cutting mechanism slide rail 10 are arranged side by side in parallel, detection mechanism base 9 is slidably connected with detection mechanism slide rail 8, and described detection mechanism is installed on On the detection mechanism base 9 , the cutting mechanism base 11 is slidingly connected with the cutting mechanism slide rail 10 , the cutting mechanism is installed on the cutting mechanism base 11 , and the positioning and clamping assembly is arranged in front of the detection mechanis...

specific Embodiment approach 2

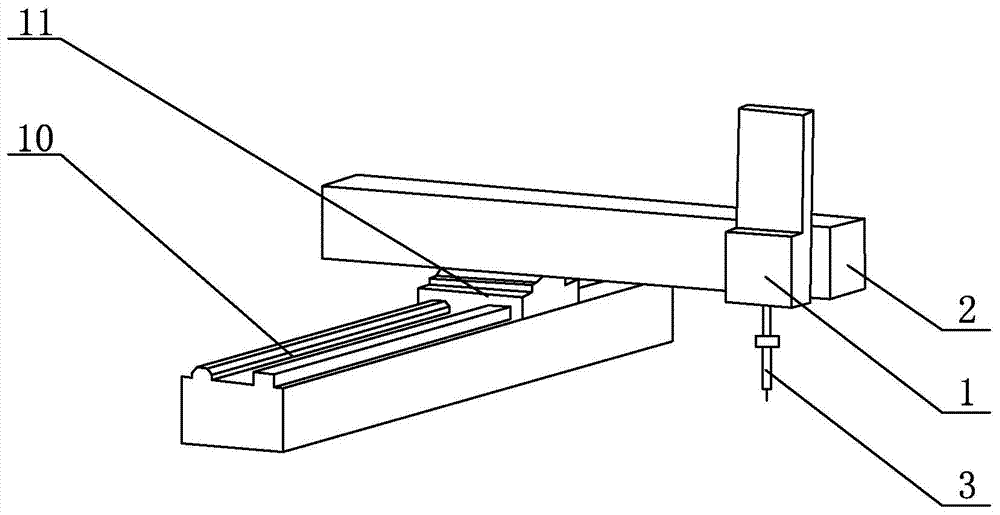

[0009] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment. The cutting mechanism of a multi-station high-pressure water cutting device with position detection function described in this embodiment includes a water jet head connection frame 1, a cantilever beam 2 and a high-pressure water jet head 3. One end of the cantilever beam 2 It is fixedly installed on the base 11 of the cutting mechanism, and the high-pressure water jet head 3 is installed on the other end of the cantilever beam 2 through the water jet head connecting frame 1 .

[0010] The technical effect of this embodiment is: with such arrangement, the water-jet head connecting frame 1 can drive the high-pressure water-jet head 3 to move linearly along the cantilever beam 2, thereby realizing precise positioning of the high-pressure water-jet head 3 and ensuring cutting accuracy. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

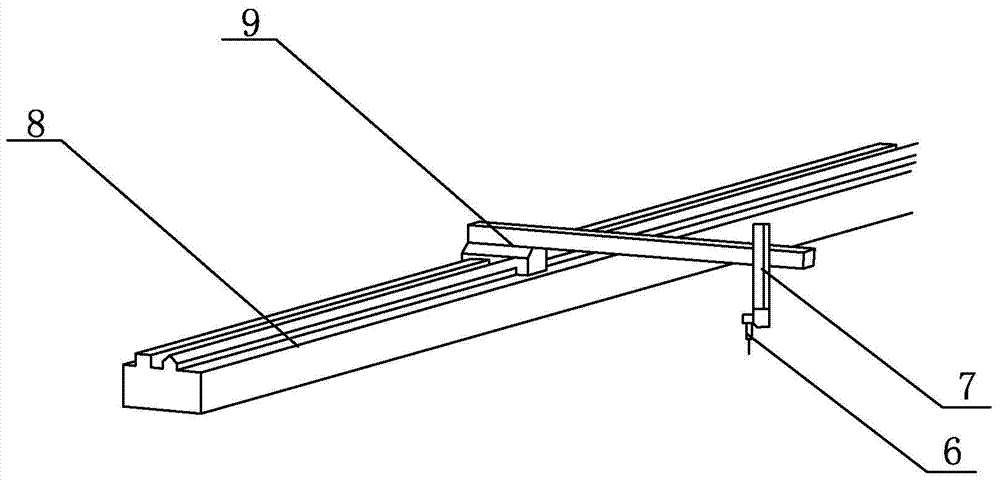

[0011] Specific implementation mode three: combination figure 1 with image 3 Describe this embodiment. The detection mechanism of a multi-station high-pressure water cutting device with position detection function described in this embodiment includes a detection head 6 and a detection head connection frame 7. The upper end of the detection head connection frame 7 is installed on the detection mechanism base 9, the detection head 6 is installed on the lower end of the detection head connecting frame 7.

[0012] The technical effect of this embodiment is: with this arrangement, the detection head connecting frame 7 can drive the detection head 6 to move linearly along the detection mechanism base 9, realizing the precise position adjustment and positioning of the detection head 6. Other components and connections are the same as those in the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap