Pulse turbulence membrane bioreactor

A bioreactor and turbulent membrane technology, applied in the field of hollow fiber membrane bioreactors, can solve problems such as clogging, low water filtration efficiency, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

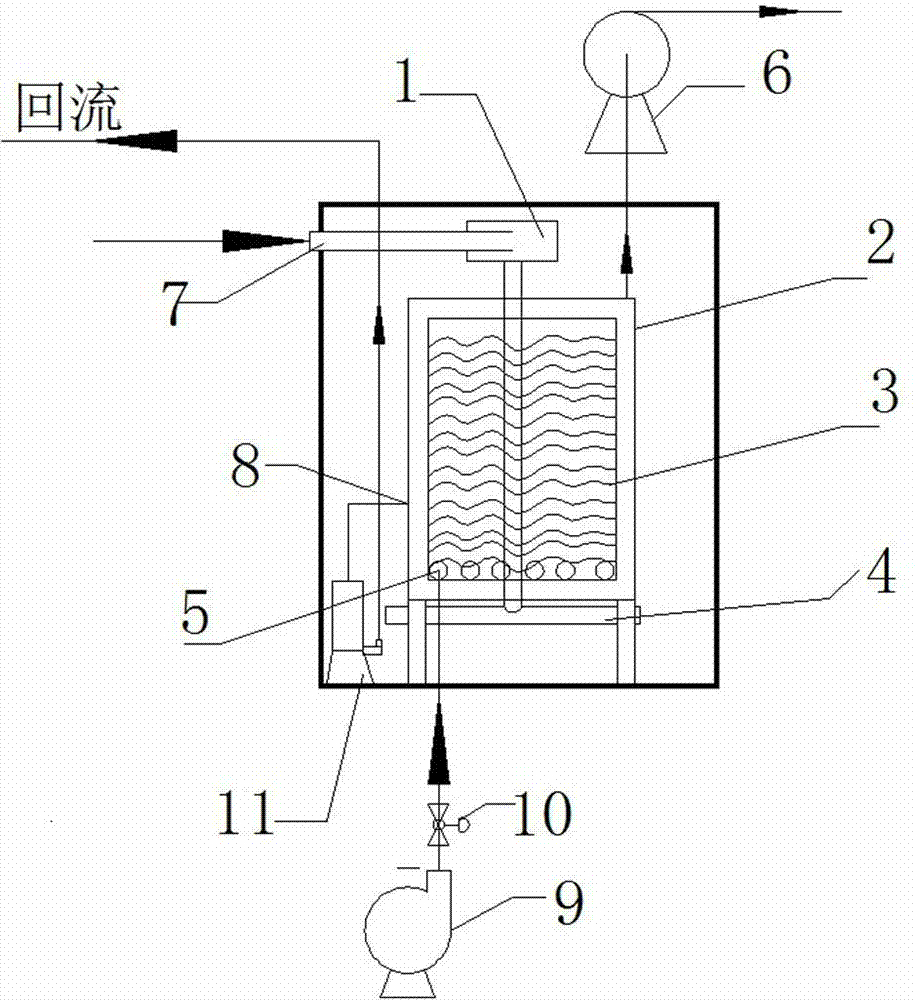

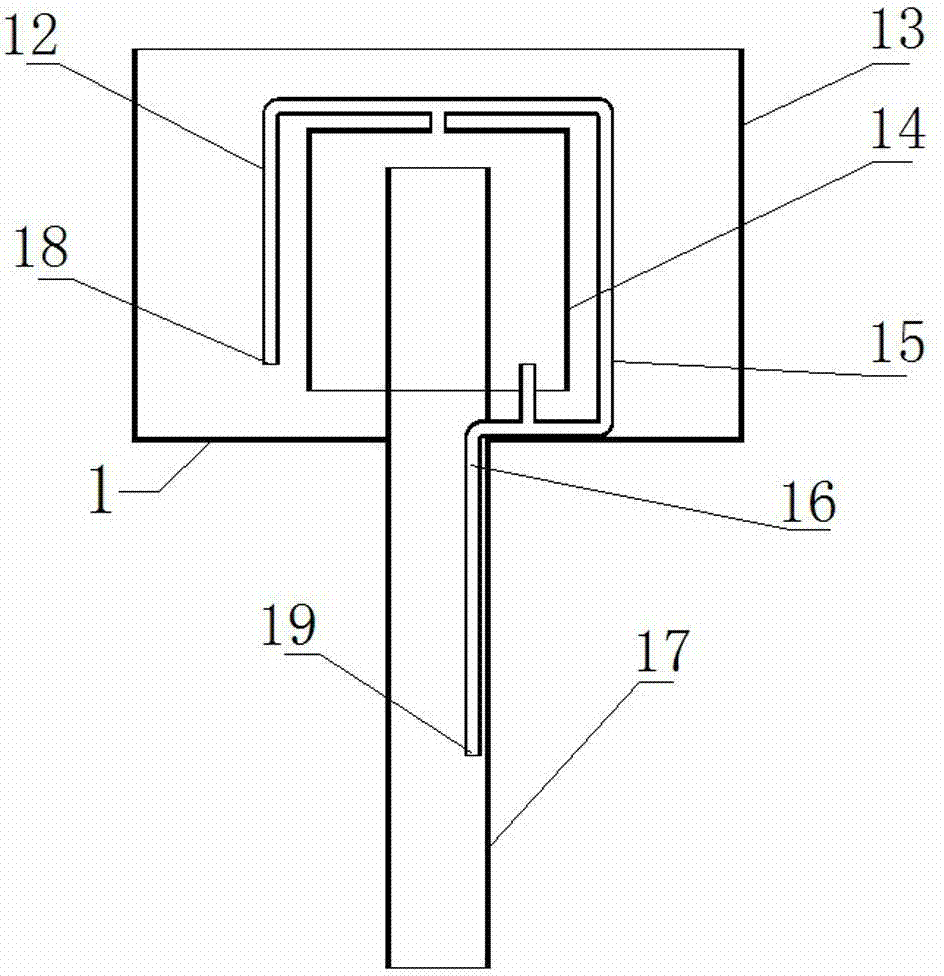

[0017] Such as figure 1 and 2 The structure of the pulse turbulent membrane bioreactor includes: a hollow fiber membrane bioreactor, a blower, a suction pump, a sludge pump and a pulse generator. The air blower 9 communicates with the aeration pipe 5 provided at the bottom of the hollow fiber membrane bioreactor with a solenoid valve 10 and a pipeline; one end of the suction pump 6 communicates with the water outlet of the hollow fiber membrane bioreactor; the sludge pump 11 is connected with the hollow fiber membrane bioreactor The sludge outlet 8 provided at the bottom of the membrane bioreactor is connected; the structure of the pulse generator 1 includes a water storage tank 13, a bell jar 14, an exhaust pipe 15, a siphon breaking pipe 12, a siphon manufacturing exhaust pipe 16 and a pulse drain pipe 17 The inside of the water storage tank 13 is provided with a bell jar 14, and one end of the pulse drain pipe 17 passes in the bell jar 14, and the other end passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com