A method for thickening biodiesel by in situ formation of organic soil

A biodiesel and organic technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of high cost and achieve cost saving, cost reduction, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

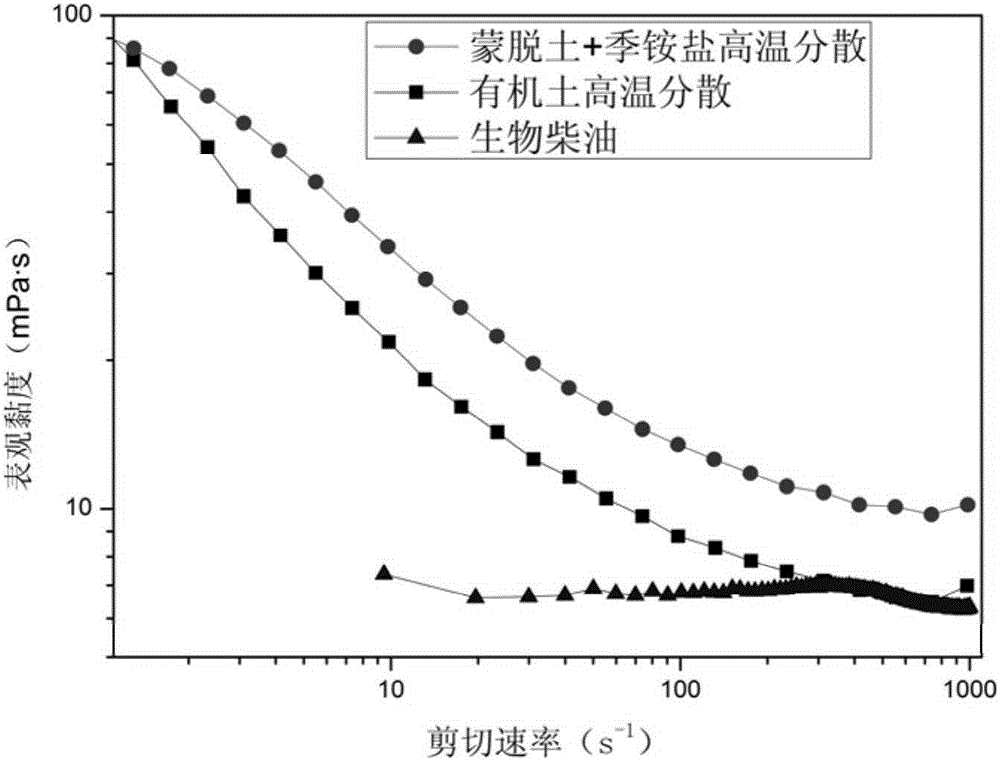

[0017] In this example, a mixed system of quaternary ammonium salt, clay and biodiesel was prepared first, and organic soil was formed in situ through proper heating and shearing, thereby thickening biodiesel, and adding organic soil synthesized in the water phase. The viscous effect was compared. The specific process is as follows:

[0018] Based on 100 parts by mass, 2.1 parts of sodium montmorillonite and 0.9 parts of cetyltrimethylammonium bromide (the amount of quaternary ammonium salt equivalent to 1.0CEC of montmorillonite used) were dispersed in 97 parts of biodiesel to prepare A mixed system with a total mass fraction of montmorillonite and quaternary ammonium salt of 3% was obtained, which was recorded as 1# sample. Weighed 0.6g of commercial organic soil and dispersed it in 19.4g of biodiesel to prepare a mixed system with a mass fraction of organic soil of 3%, which was recorded as 2# sample. These two samples and the biodiesel viscosity curves used are as follow...

Embodiment 2

[0020] This embodiment is to prepare clay and a system in which the mass fraction of single-chain quaternary ammonium salt is 10%, and the specific process is as follows:

[0021] Based on 100 parts by mass, 7 parts of sodium montmorillonite, 3 parts of cetyltrimethylammonium bromide (the amount of quaternary ammonium salt added is approximately equal to 1.0CEC of montmorillonite used), dispersed in 90 parts of biodiesel, and prepared A mixed system with a mass fraction of montmorillonite and quaternary ammonium salts of 10% was obtained, and then the sample was sealed and placed in a water bath at 80°C for 1 hour, then transferred to a colorimetric tube and left to stand at room temperature. It is known that this sample turns into a gel after cooling to room temperature, such as figure 2 shown.

Embodiment 3

[0023] This embodiment is to prepare clay and a double-chain chain quaternary ammonium salt with a mass fraction of 10%, and the specific process is as follows:

[0024] Based on 100 parts by mass, 5.4 parts of sodium montmorillonite, 4.6 parts of dioctadecyl dimethyl ammonium chloride (the amount of quaternary ammonium salt is approximately equal to 1.2CEC of the montmorillonite used) are dispersed in 90 parts of biodiesel, Prepare a mixed system of montmorillonite and quaternary ammonium salt with a mass fraction of 10%, then seal the sample and place it in a water bath at 80°C for 1 hour at constant temperature, then transfer it to a colorimetric tube and let it stand at room temperature. As a result, the sample turned into a gel after cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com