Method and device for regulating temperature of hearth of ternary ignition furnace

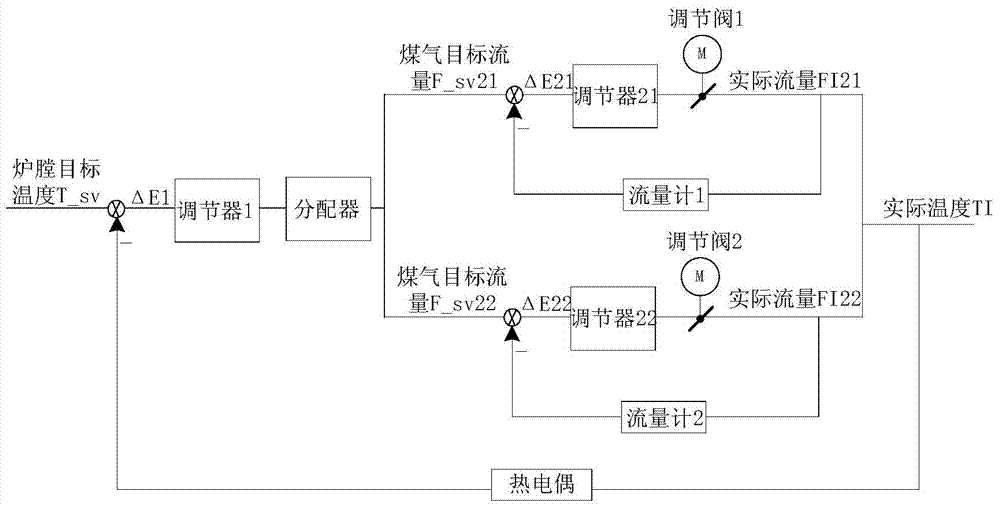

A furnace temperature and adjustment method technology, which is applied in the direction of combustion method, fuel supply adjustment, furnace, etc., can solve the problems of large lag, long response time of furnace temperature, and increased labor intensity of operators, so as to shorten the response time and reduce the hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

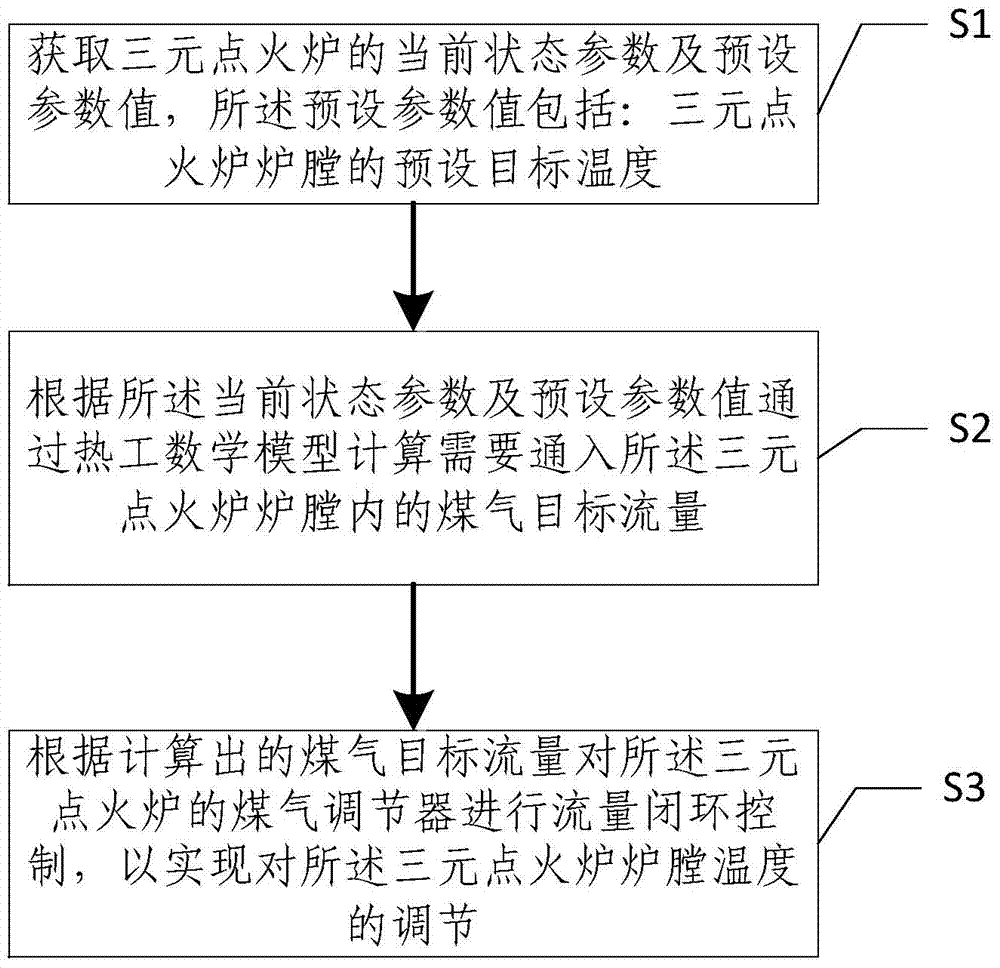

[0108] The present invention is described below with a specific embodiment, but the protection scope of the present invention is not limited. refer to Figure 4 , the method of this embodiment includes the following steps:

[0109] Step 101: Program calculation starts.

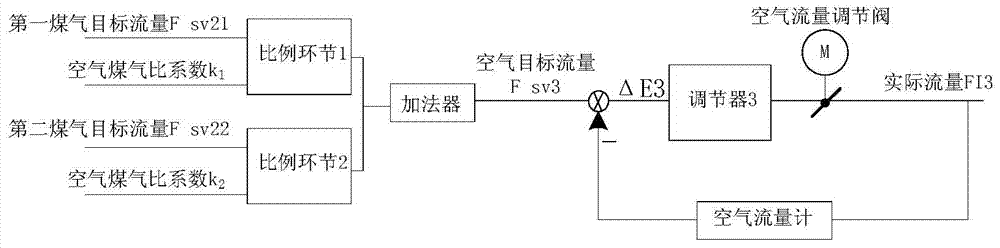

[0110] Step 102: Read relevant preset parameters, the preset parameters include: preset target temperature T 炉 , furnace area S 炉 , the height H from the bottom of the trolley to the top of the furnace 0 , the average constant pressure specific heat of the flue gas in the furnace C 烟 , gas average specific heat at constant pressure C 煤1 and C 煤2 , the average specific heat of air at constant pressure C 空1 and C 空2 , the lower calorific value q of gas 煤1 and q 煤2 , heat intensity coefficient ε of ignition furnace, air-gas ratio coefficient k 1 and k 2 , the gas label to be fixed and the preset flow rate of the gas to be fixed (when the first gas is fixed, it is F 煤1 , when the second gas is fixed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com