Method for directional energy-gathered blasting of retaining wall with low damage

A low-damage, energy-gathering technology, applied in blasting and other directions, to achieve the effects of reducing surrounding rock damage, weakening damage, and strengthening directional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

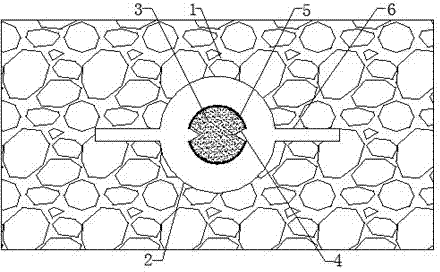

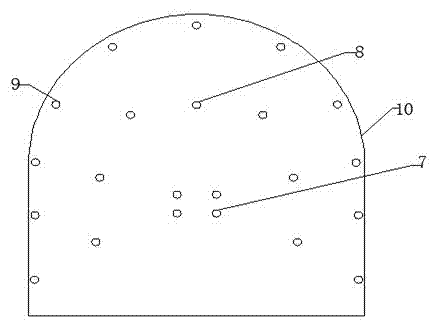

[0020] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , figure 2 As shown, a low-damage directional energy-concentrated wall blasting method includes the following steps:

[0021] (1) Drilling: Use a drilling rig to drill holes into the pre-excavated tunnel rock mass. The peripheral holes, caving holes and cutting holes are all 40mm, and the construction is carried out to the exact position according to the tunneling blasting plan;

[0022] ⑵High-pressure water jet grooving: Carry out hydraulic grooving on the peripheral eye, so that the grooving direction is consistent with the roadway contour line, and two rectangular slits are formed on the hole wall after grooving;

[0023] (3) Charging: put the shaped charge into the slit tube, the diameter of the slit tube is 36mm, and then put the charged slit tube into the drilled hole, so that the energy-gathering groove of the shaped charge and the tube of the slit tube The ...

Embodiment 2

[0033] A low-damage directional energy-gathering wall blasting method, comprising the following steps:

[0034] (1) Drilling: use the drilling rig to drill holes into the pre-excavated tunnel rock mass, and construct to the exact position according to the roadway excavation and blasting plan;

[0035] ⑵High-pressure water jet grooving: Carry out hydraulic grooving on the peripheral eye, so that the grooving direction is consistent with the roadway contour line, and two rectangular slits are formed on the hole wall after grooving;

[0036] (3) Charging: Put the energy-shaping charge into the slit tube, and then put the charged slit tube into the drill hole, so that the energy-gathering groove of the energy-shaping charge, the slit of the slit tube and the slot of the hole wall same direction;

[0037] ⑷Seal the hole: use yellow mud to seal the hole, and ensure that the detonation system is intact;

[0038] ⑸ Blasting: The electric detonation system is used for detonation. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com