Alternating Stress Measuring Device and Method for Ferromagnetic Components

A measuring device and technology of alternating stress, which is applied in the direction of material magnetic variable and the measurement of the change force of material magnetic properties caused by the applied stress, can solve the problems that need to be verified, and achieve the effect of broad application background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

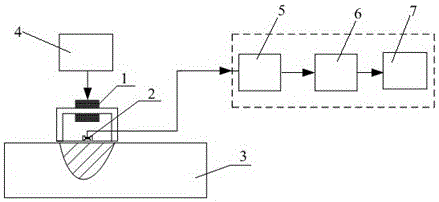

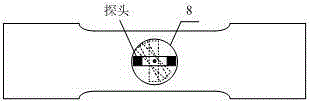

[0017] Such as figure 1 As shown, the detection principle of the method of the present invention is as follows figure 1 Shown: Exciting probe 1 magnetizes the component 3 under inspection, and generates a uniform induced current on the surface of component 3. When there is no stress in component 3, the surface induced current flows uniformly; if there is stress on or near the surface of component 3, due to the 3 The distribution and magnitude of the magnetic permeability are different, and the induced current is disturbed in the stress area, which causes the electromagnetic field on the surface of the component 3 to change. The detection probe 2 picks up the induced magnetic field above the stress area, and the stress information can be obtained through signal conditioning and analysis.

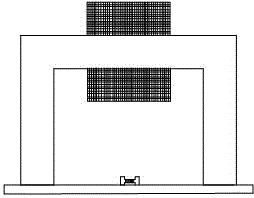

[0018] Such as Figure 2~3 As shown, the ferromagnetic component alternating stress measurement system device and method of the present invention comprise the following steps:

[0019] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com