Non-continuity lithium battery thin film defect detection method and device based on machine vision

A machine vision, film defect technology, applied in the direction of optical testing flaws/defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

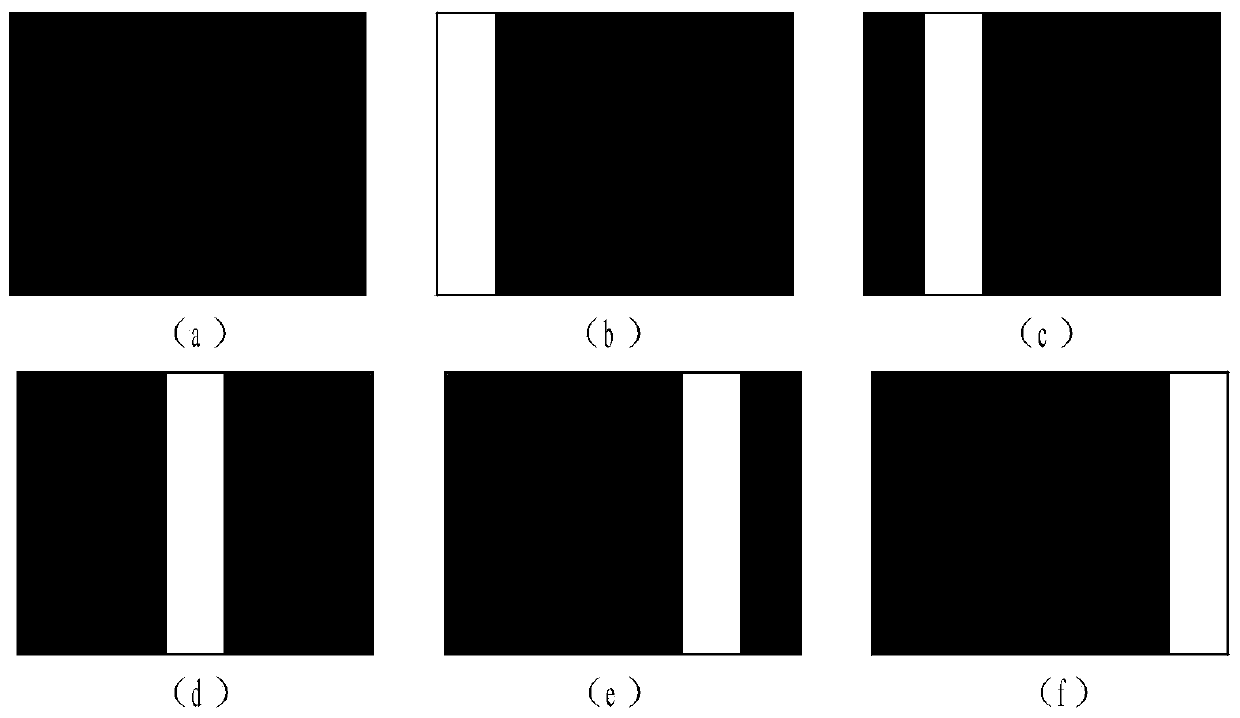

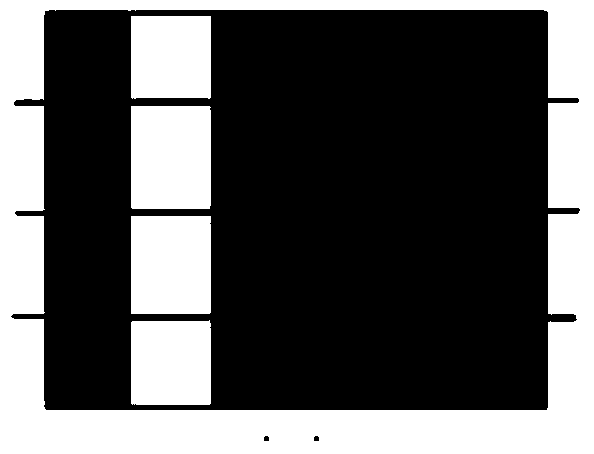

Image

Examples

Embodiment 1

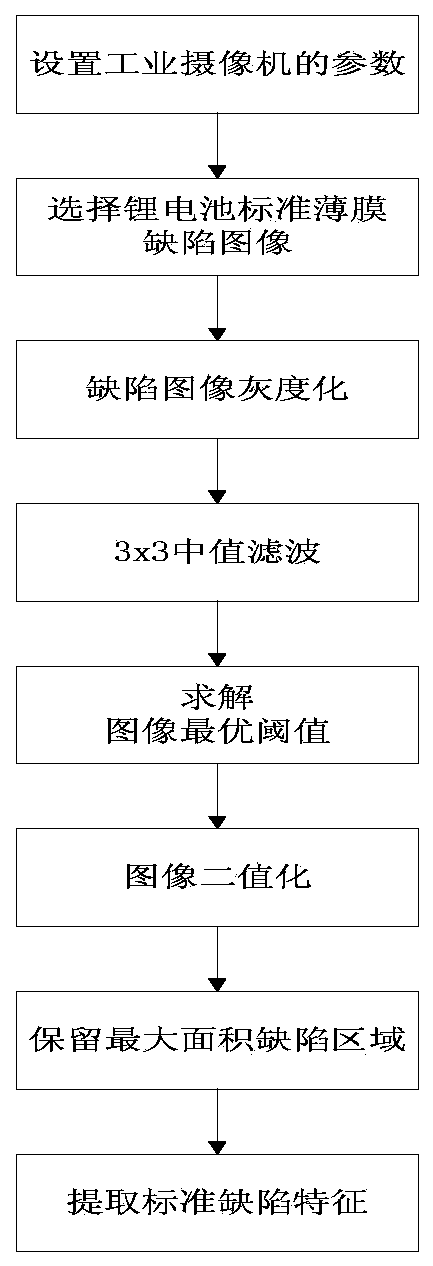

[0084] The non-continuous lithium battery film defect detection method based on machine vision of the present invention comprises the following steps:

[0085] The threshold judgment method realizes the extraction of the continuous defect-free film from the discontinuous defect-free film by step 1, and the construction of the template feature value of the continuous defect film is realized by step 2.

[0086] Step 1, using the threshold judgment method to realize the extraction of continuous and defect-free films from discontinuous and defect-free films;

[0087] Step 1.1, set the parameters of the industrial camera for capturing clear images;

[0088] Step 1.2, using an industrial camera to shoot a non-continuous non-defective film, and sending the obtained standard image to the computer;

[0089] Step 1.3, performing grayscale processing on the standard image;

[0090] Step 1.4, performing 3×3 median filtering on the standard image after grayscale processing;

[0091] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com