Separate N2O selective microelectrode and preparation method thereof

A micro-electrode, separated technology, applied in the field of separated N2O selective micro-electrode and its preparation, can solve the problem of dwelling, and achieve the effect of short response time, high resolution and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples, but the examples do not constitute a limitation to the present invention.

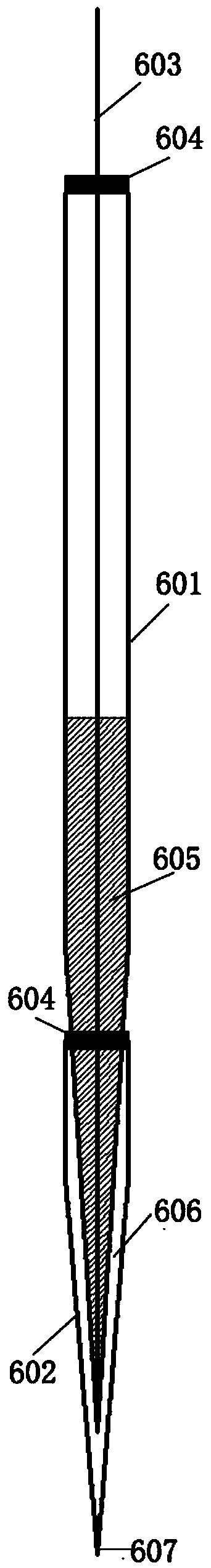

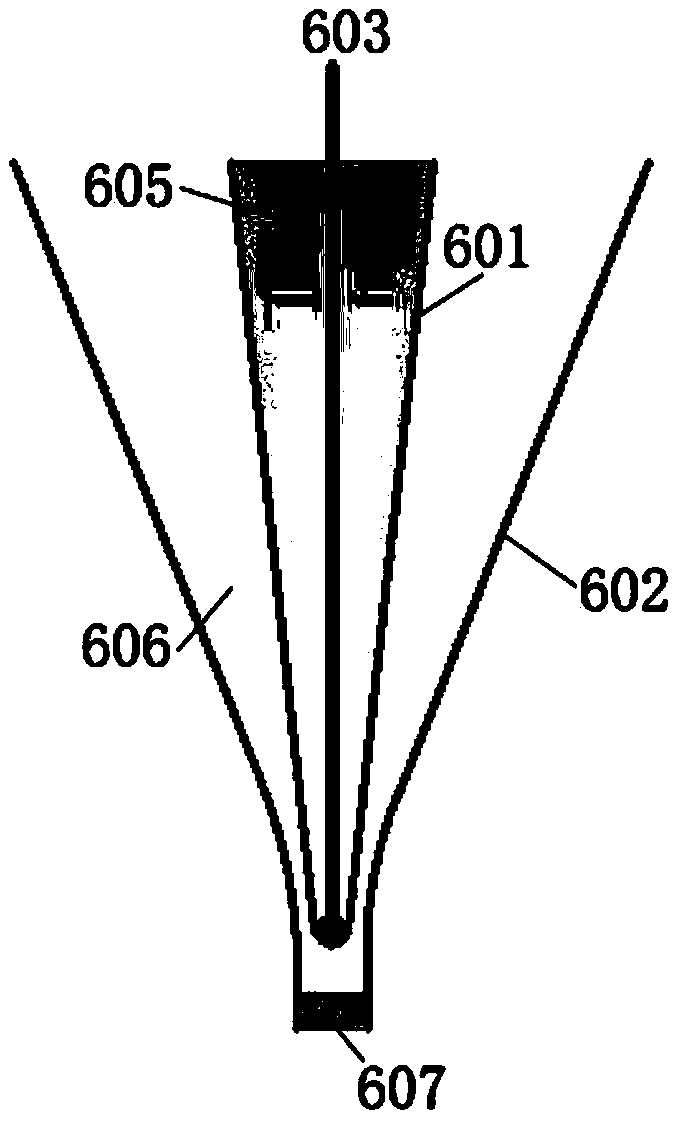

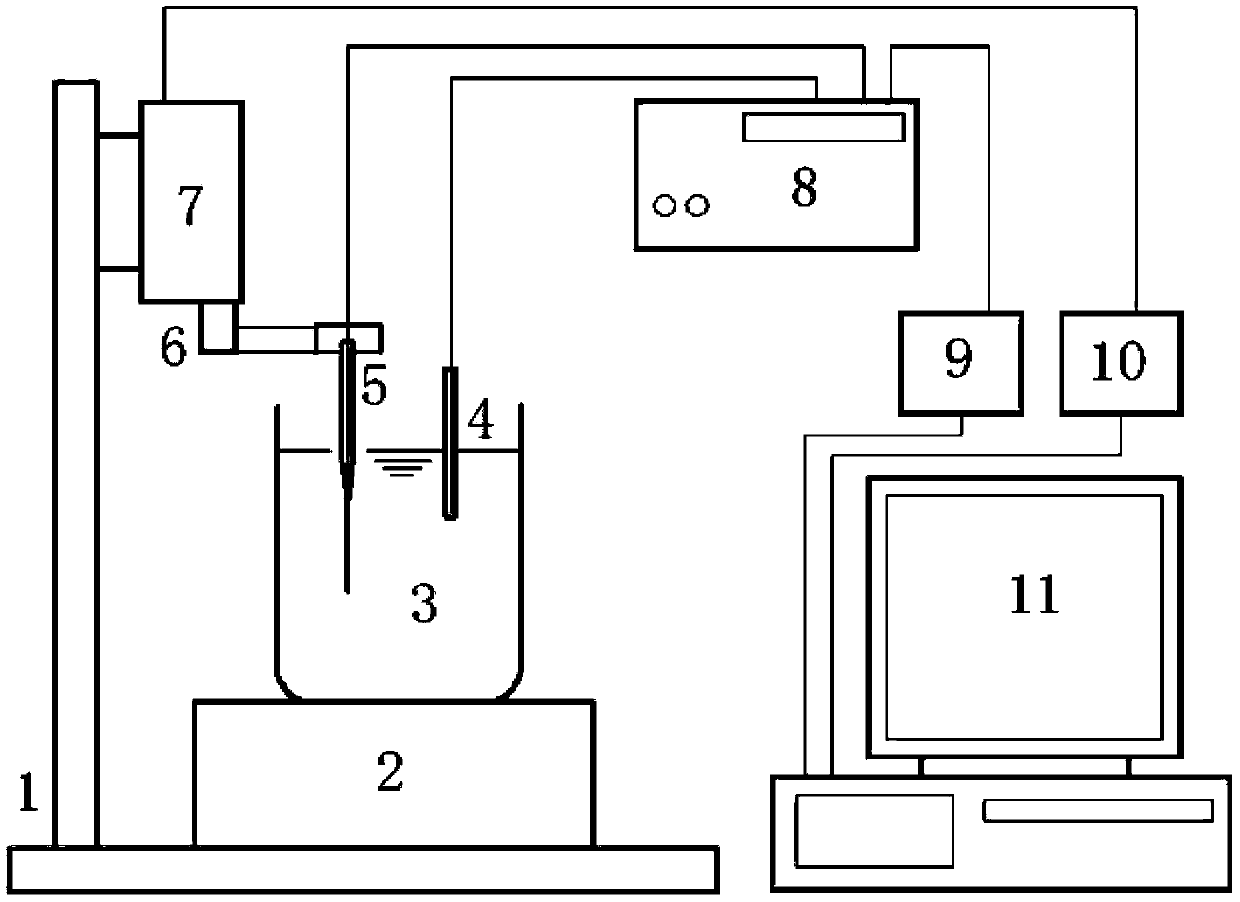

[0040] see figure 1 , figure 2 As shown, the separation formula N is given 2 O select the structure of the microelectrode, the microelectrode includes a tubular conical glass tube electrode 601 filled with bismuth alloy 605 and wrapped with a thin copper wire 603, and a sleeved at its lower end, filled with ascorbate solution 606, and the tip is made of silica gel A membrane 607 closes the outer tubular tapered glass sleeve 602 . The thin copper wire 603 inside the tubular tapered glass tube electrode 601 protrudes from the cylindrical end surface of the tubular tapered glass tube electrode 601 to connect with the microvoltmeter, and the cylindrical end surface is sealed with epoxy resin 604; the tubular tapered glass tube electrode 601 The place where the cylindrical end surface is socketed with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com