Automated micromachining device based on acoustic pressure

A micro-machining and pressure technology, applied in the field of automatic micro-machining devices based on sound pressure, can solve the problems of difficult automatic processing, high price, difficult operation, etc., and achieve the effect of simple structure, low production cost and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] specific implementation

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

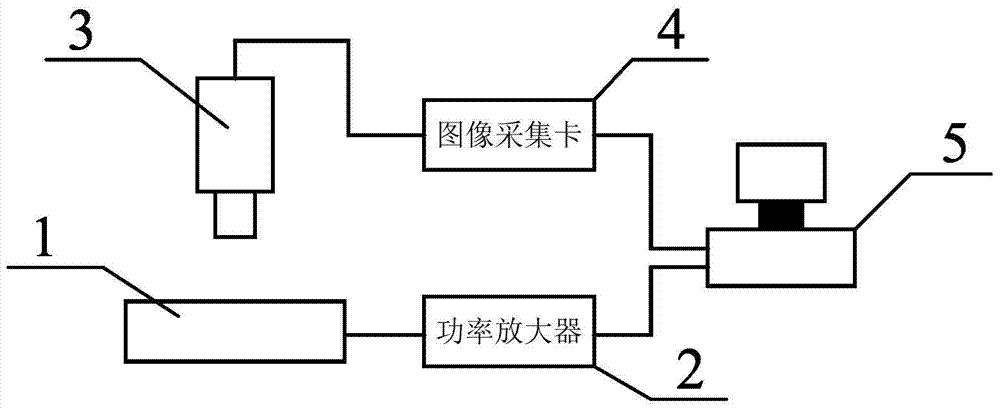

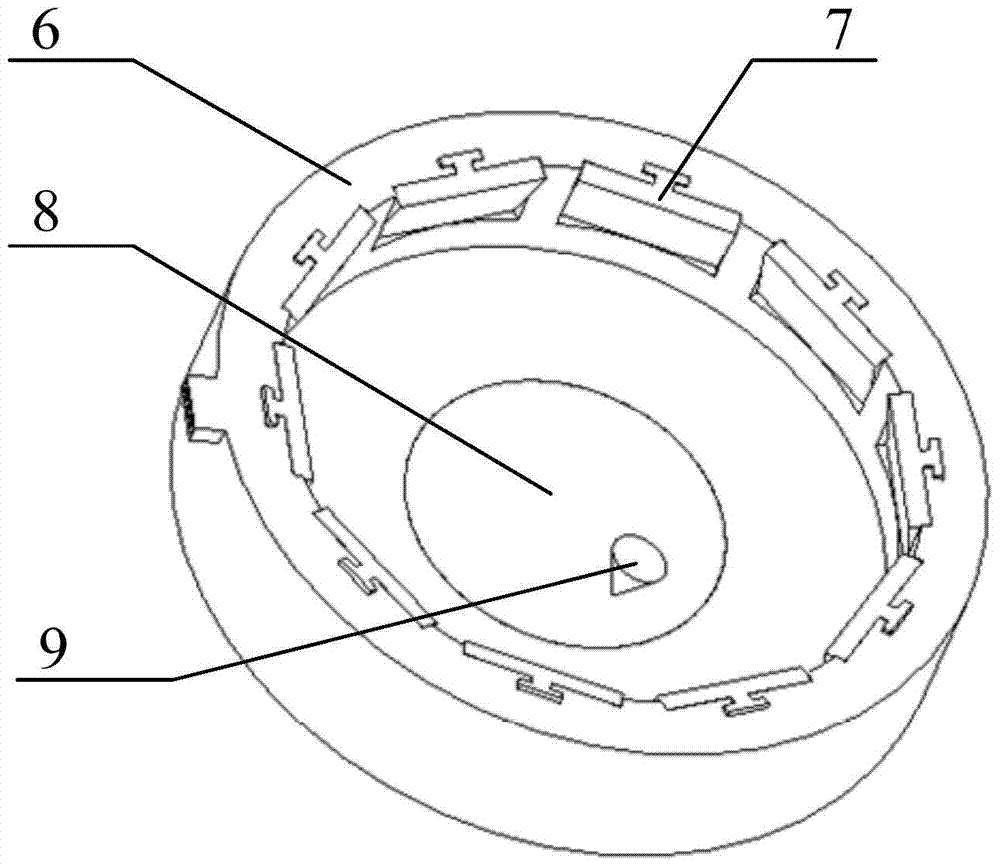

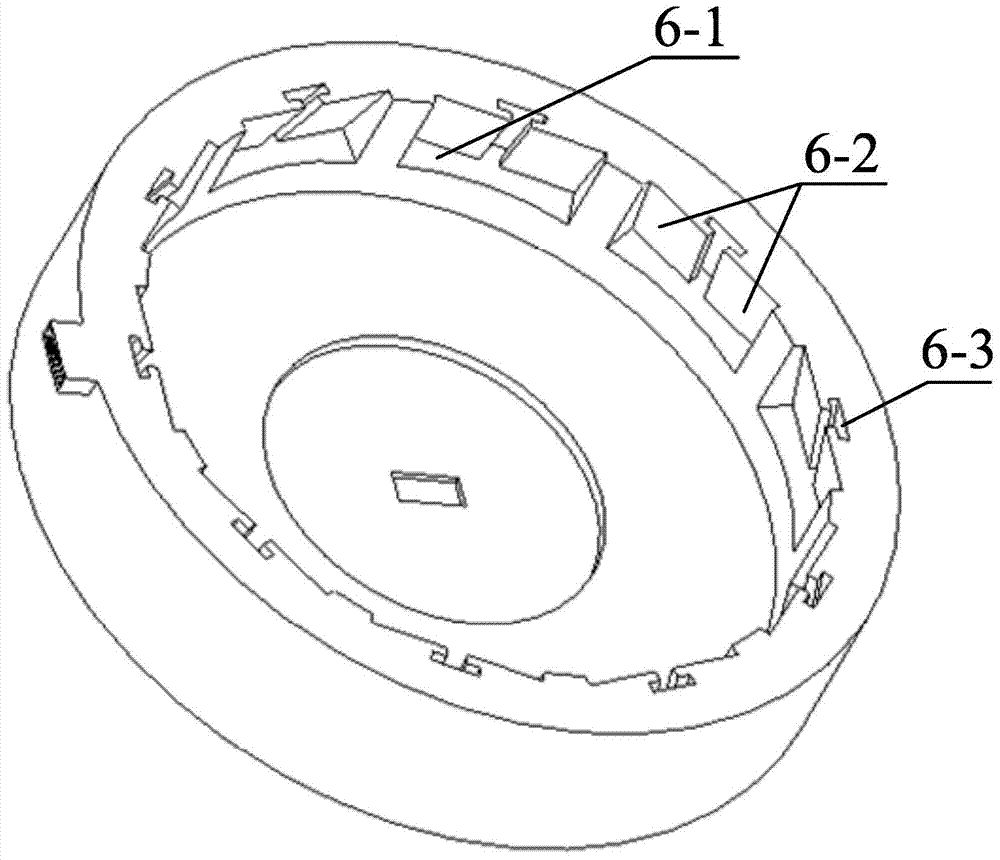

[0040] Such as figure 1 As shown, the present invention comprises power amplifier 2, high-speed camera 3, image acquisition card 4, industrial computer 5 and processing module 1, and power amplifier 2 is connected with industrial computer 5 by data line, and high-speed camera 3 is connected with image acquisition card by data line 4-phase connection, the image acquisition card 4 is connected with the industrial computer 5 through the PXI bus; the processing module 1 is connected with the power amplifier 2 through the communication port 6-5 through the data line; as figure 2As shown, the processing module 1 includes a driving seat 6, a transducer 7, a shelf 8 and a microknife 9 for cooperating with the transducer 7 to realize processing, and the inner edge of the blind hole in the center of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com