Method for preparing metal probe on basis of electrochemical etching and device

A technology of metal probes and etching devices, which is applied in measuring devices, scanning probe technology, scanning probe microscopy, etc., can solve the problems of high cost, high cost, and small weight, etc., to protect the needle tip , The effect of reducing the radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a preparation method for preparing tungsten needles, comprising the following steps:

[0035] (1) Preparation of layered solution: 80 g of solid sodium hydroxide was weighed, dissolved in deionized water to form a 1 L solution, and a sodium hydroxide solution with a concentration of 2M was obtained for later use. Slowly pour the fluorocarbon solvent into the reaction tank until the depth of the fluorocarbon solvent is about 1 cm. Then take a certain amount of sodium hydroxide solution and pour it into the reaction tank, you can see that the sodium hydroxide solution is floating on the fluorocarbon solvent, and ensure that the depth of the sodium hydroxide solution is 1cm.

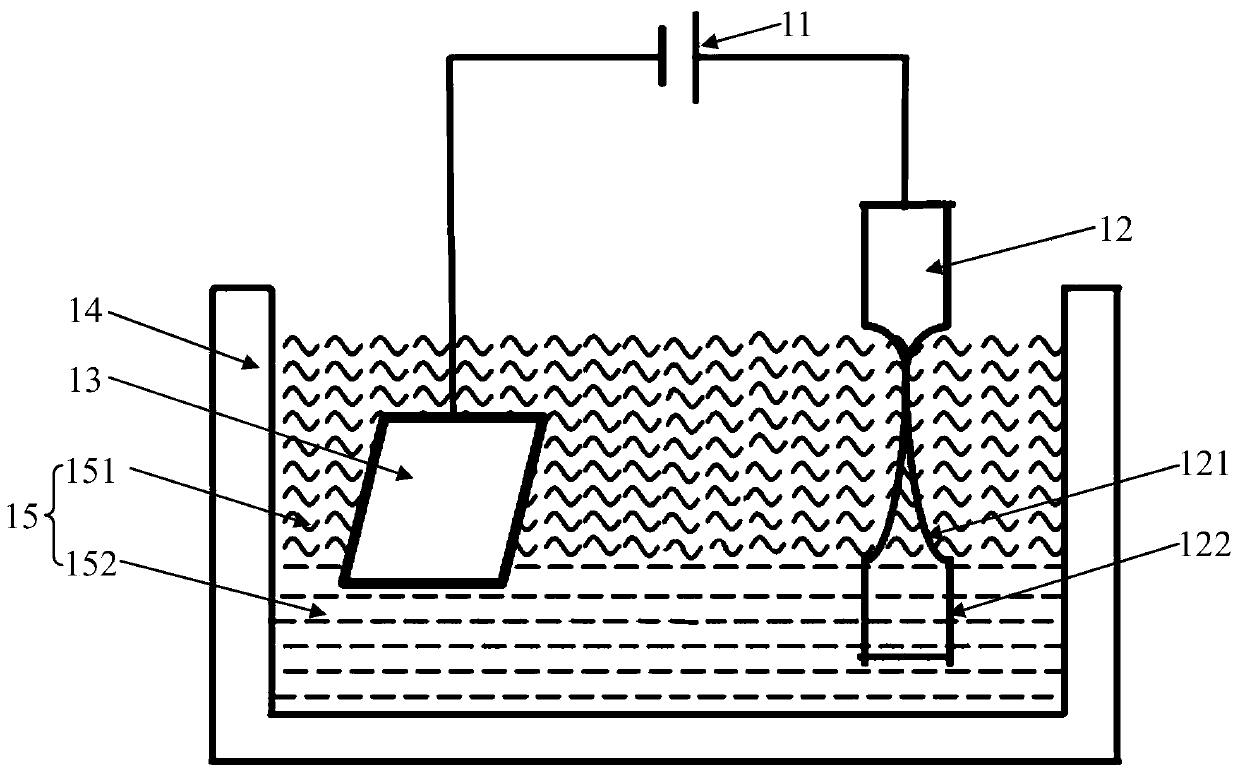

[0036] (2) figure 1 It is a schematic diagram of an electrochemical etching device for preparing thick metal probes, including a power supply 11, a metal wire 12 and an electrode 13 respectively connected to two poles of the power supply, and an electrochemical cell 14, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com