Surface plasmon imaging photoetching structure

A surface plasmon and imaging technology, which is used in microlithography exposure equipment, photolithography process exposure devices, etc. It is difficult to break through the resolution and other issues to achieve the effect of high lithography resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

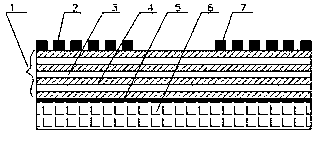

[0014] like figure 1 As shown, the present invention consists of a superlens structure (1), a first grating (2), a resist layer (5), a substrate (6) and a second grating (7). The first grating (2) and the second grating (7) are located above the super lens structure (1), and the resist layer (5) is located below the super lens structure (1). The super lens structure (1) is composed of multilayer dielectric films (3) and multilayer metal films (4) alternately. When the first grating (2), the second grating (7) are made of gold, the material of the dielectric film (3) is silicon dioxide, and the material of the metal film (4) is gold or silver or aluminum, the dielectric film (3) and the metal film (4) When the thickness is 10nm~100nm, it is a surface plasmon imaging lithography structure for i-line 365nm lithography.

[0015] When illuminated by a 365nm ultraviolet li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com