Coil winding machine for stereoscopic wound iron core transformer

A three-dimensional winding core and winding machine technology, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, mechanical equipment, etc., can solve the problems of coil winding and lead wire processing difficulties, so as to reduce the difficulty of lead wire processing, facilitate operation, Applied with good prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

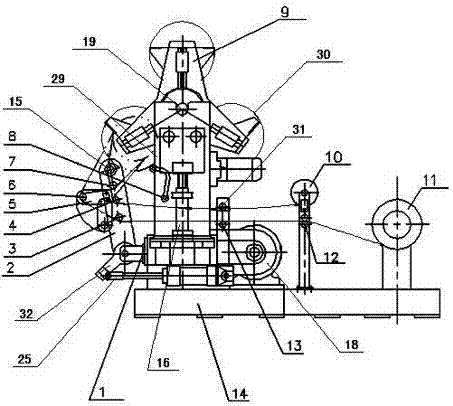

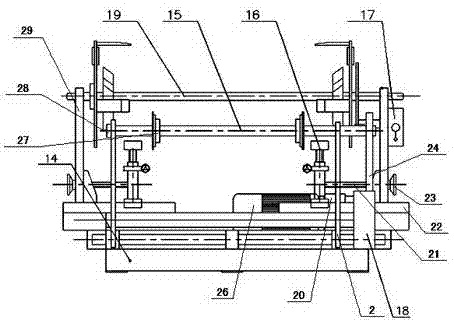

[0024] see figure 1 and figure 2 Summary of the invention: the present invention is the winding machine of three-dimensional wound core transformer, and it comprises support 14 and the clamping mechanism that is arranged on the support 14, winding transmission mechanism, wire material support mechanism, auxiliary support mechanism.

[0025] Wherein, the clamping mechanism is mainly composed of a clamping bracket 29 , a central shaft 19 , an iron core turning jig 9 and a turning driving device 17 . The clamping bracket 29 is fixed on both sides of the machine base 14. In order to adapt to the clamping of iron cores of different specifications and sizes, the clamping bracket on one side should be fixed, and the other side should be slidably assembled (such as the guide rail auxiliary structure or dovetail groove structure, etc.) On the base 14, the adjustment of the distance between the clamping brackets 29 on both sides is realized by slidingly adjusting the clamping brackets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com