fuel dispenser

A fuel distributor and fuel cavity technology, which is applied in the directions of low pressure fuel injection, low pressure fuel injection, fuel injection device, etc., can solve problems such as the limitation of application scope, and achieve the effects of improving compressive strength, improving strength and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

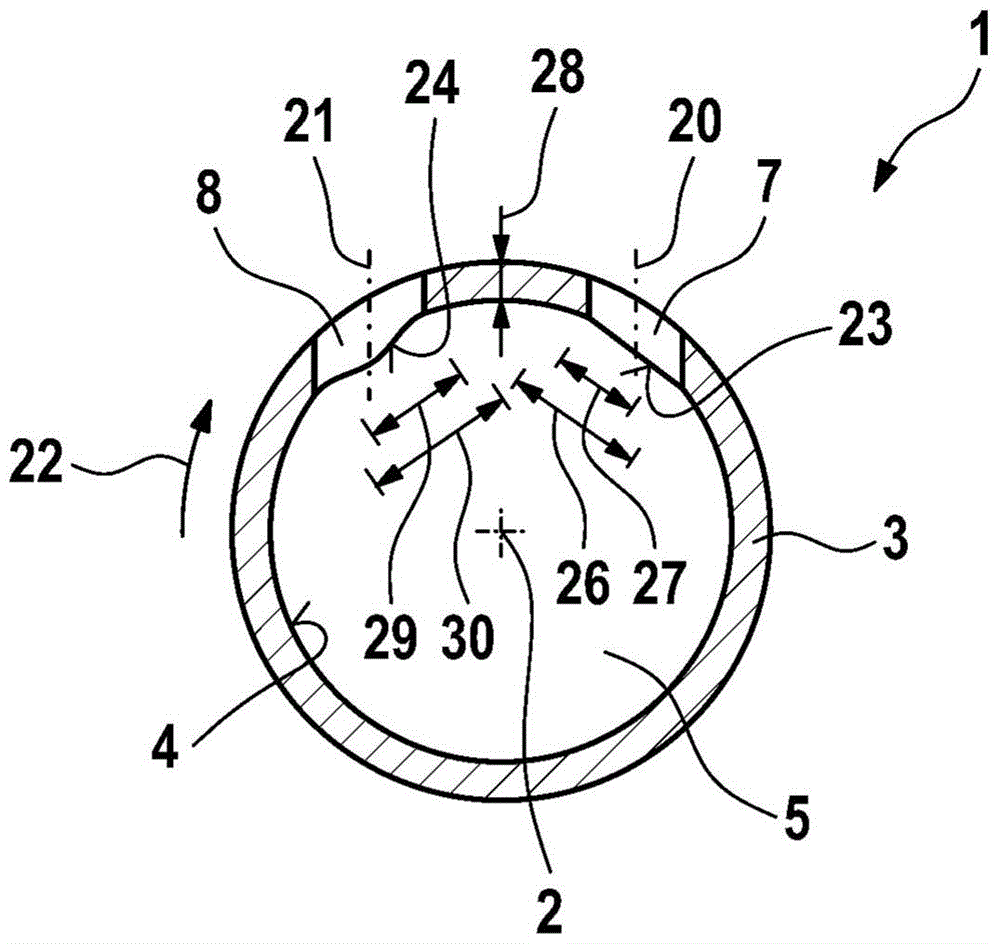

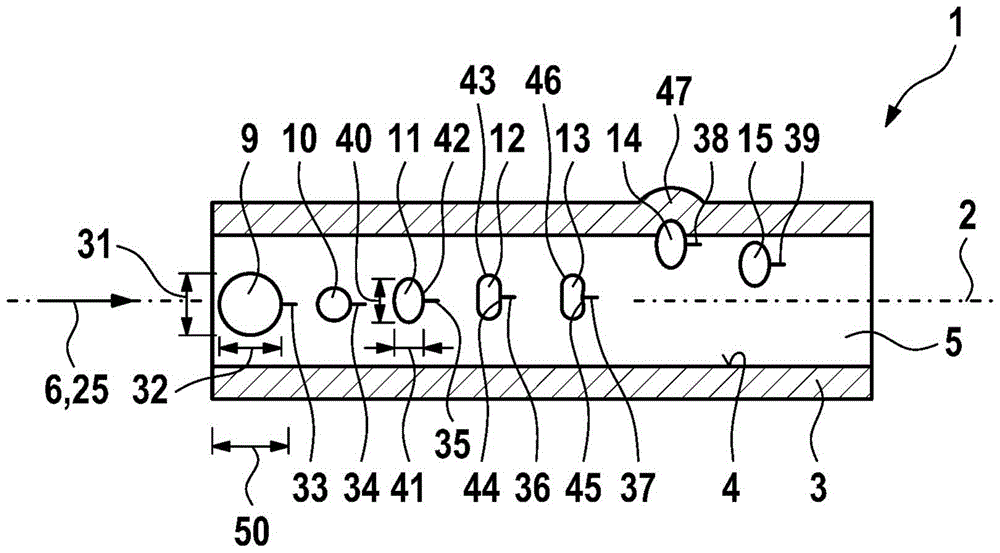

[0016] figure 1 The fuel distributor 1 is shown schematically in a cross-sectional view to illustrate possible configurations of the invention, wherein the cut plane is perpendicular to the longitudinal axis 2 ( figure 2 )orientation. The fuel distributor 1 has a tubular base body 3 . In particular, the tubular base body 3 is substantially hollow-cylindrical. Of course, it can also be in other configurations. For example, the tubular base body 3 has a decircular cross section. In order to simplify the illustration, other elements of the fuel distributor 1 are not shown. Such an element can in particular be a cup-shaped structure for connecting the fuel distributor 1 to the fuel injection valve.

[0017] The fuel distributor 1 can in particular be designed in the form of a fuel distributor pressure plate 1 . The fuel distributor 1 is especially suitable for hybrid compression externally ignited internal combustion engines. In particular, the fuel distributor 1 is here a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com