Iron ore mixing bucket device

A technology for mixing barrels and iron ore, applied in the direction of mixers, mixing methods, liquid and solid mixing, etc., can solve problems such as blocking the furnace gas ascending channel, affecting the smelting process, loose iron filings are easy to float on the furnace lining, etc. , to achieve the effect of preventing tilt offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

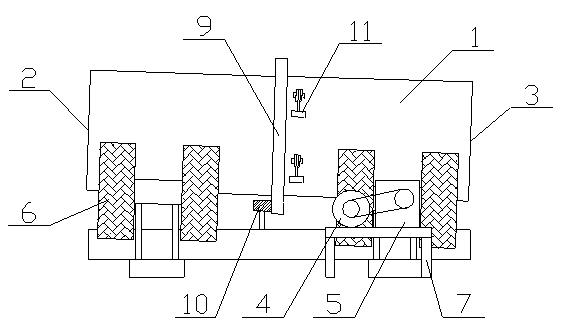

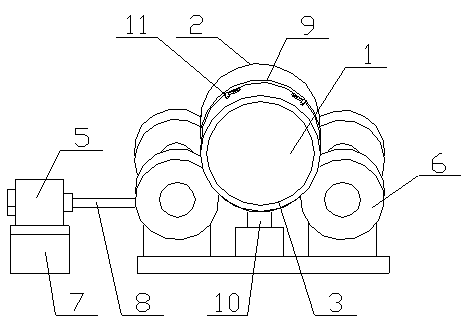

[0013] Such as figure 1 , 2 As shown, the present invention discloses an iron ore mixing barrel device, which comprises a mixing barrel 1, the two ends of the mixing barrel 1 are respectively a feed end 2 and a discharge end 3, and the mixing Bucket 1 is set as 15 °-20 ° inclination, and one side of described mixing bucket 1 is provided with motor 4 and speed reducer 5, and described motor 4 and described speed reducer 5 are connected by belt, and described mixing bucket 1 Both sides are provided with tires 6, the tires 6 are arranged on the frame 7, the speed reducer 5 is connected to the frame 7 through the transmission shaft 8, the tread of the tire 6 is connected with the mixing bucket 1 The surface of the bucket is vertically contacted, the upper circumference of the mixing bucket 1 is provided with a circle of protrusions 9, and the bottom of the mixing bucket 1 is provided with a small pulley 10, and the small pulley 10 is arranged on the protrusion 9 facing the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com