Coating for lost foam casting, and preparation method thereof

A lost foam casting and coating technology, which is applied to casting molding equipment, coatings, molds, etc., and can solve problems such as high cost and poor coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In addition, the present invention also provides a preparation method of the above-mentioned coating for lost foam casting, the preparation method comprising:

[0037] Step 1, mixing quartz sand and bauxite to obtain refractory aggregate, wherein the weight ratio of quartz sand to bauxite is 3:7 to 4:6;

[0038] Step 2, adding water to the refractory aggregate and stirring; and

[0039] Step 3, adding suspending agent and binder to the mixture of refractory aggregate and water and stirring.

[0040] Wherein, the time for stirring and mixing quartz sand and bauxite in step 1 can be determined according to actual conditions, and it is a standard to mix quartz sand and bauxite as fully as possible. Usually, the time for stirring in step 1 The time is 5min-10min; similarly, the time for stirring in step 2 can also be determined according to the actual situation, so that the quartz sand and bauxite are dispersed in water as uniformly as possible as a standard, usually, the ...

Embodiment

[0051] Coating samples 1-8 for lost foam casting were prepared according to the following steps, respectively:

[0052] Step 1. Stir and mix the components of the refractory aggregate. The components and proportions and average particle size of the refractory aggregate in samples 1-8 are shown in Table 1. During the preparation process of samples 1-8, carry out The time of stirring is shown in table 4 respectively;

[0053] Step 2: Add water to the refractory aggregate and stir, wherein the weight ratios of water and refractory aggregate in samples 1-8 are shown in Table 1, and the time of stirring during the preparation of samples 1-8 is in step 2 The time for stirring is shown in table 4 respectively; and

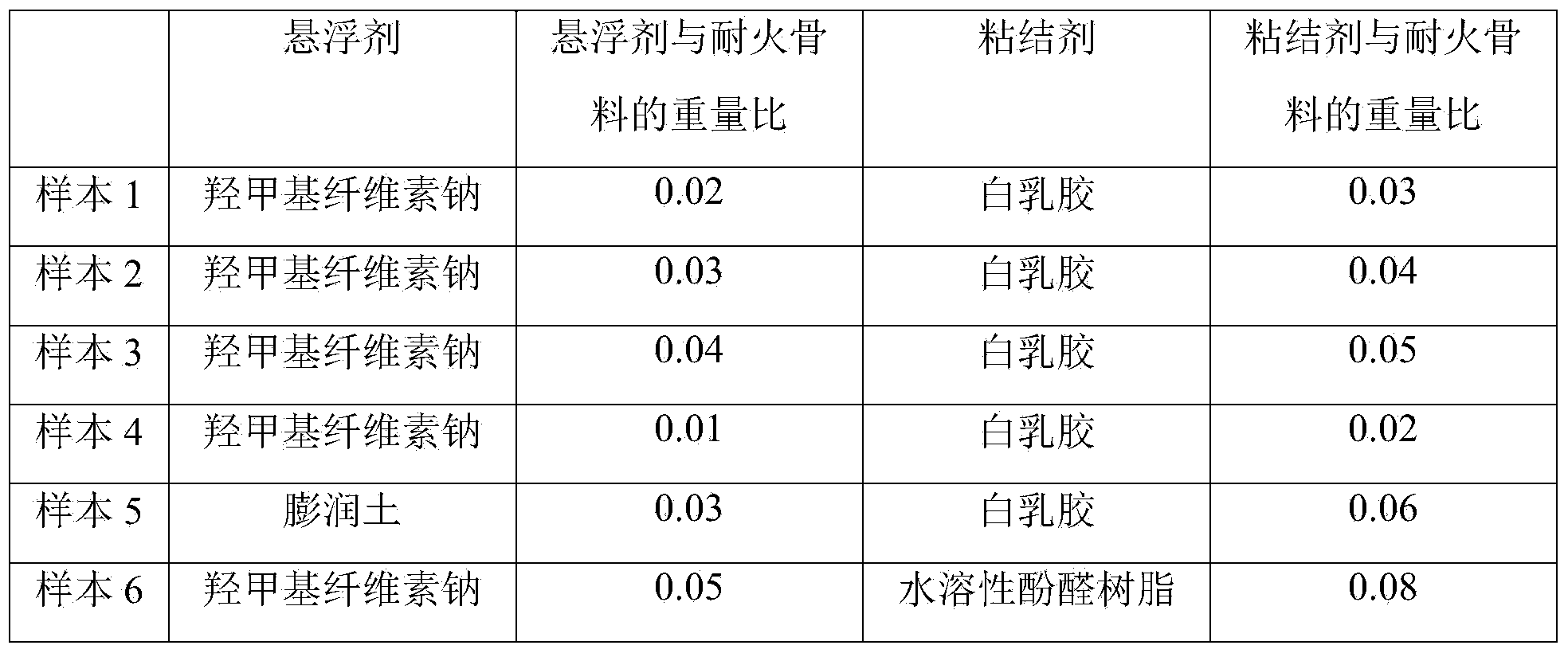

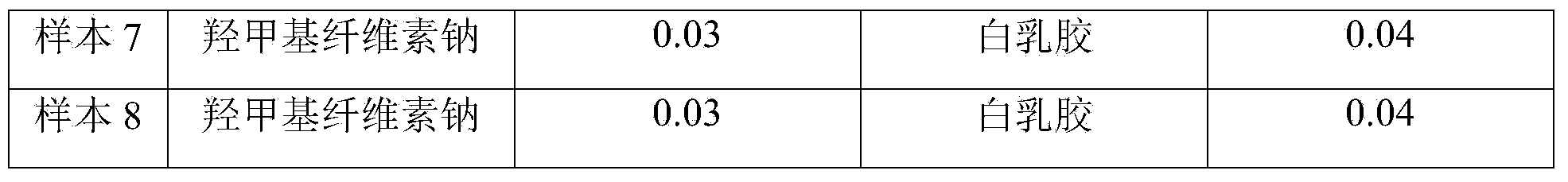

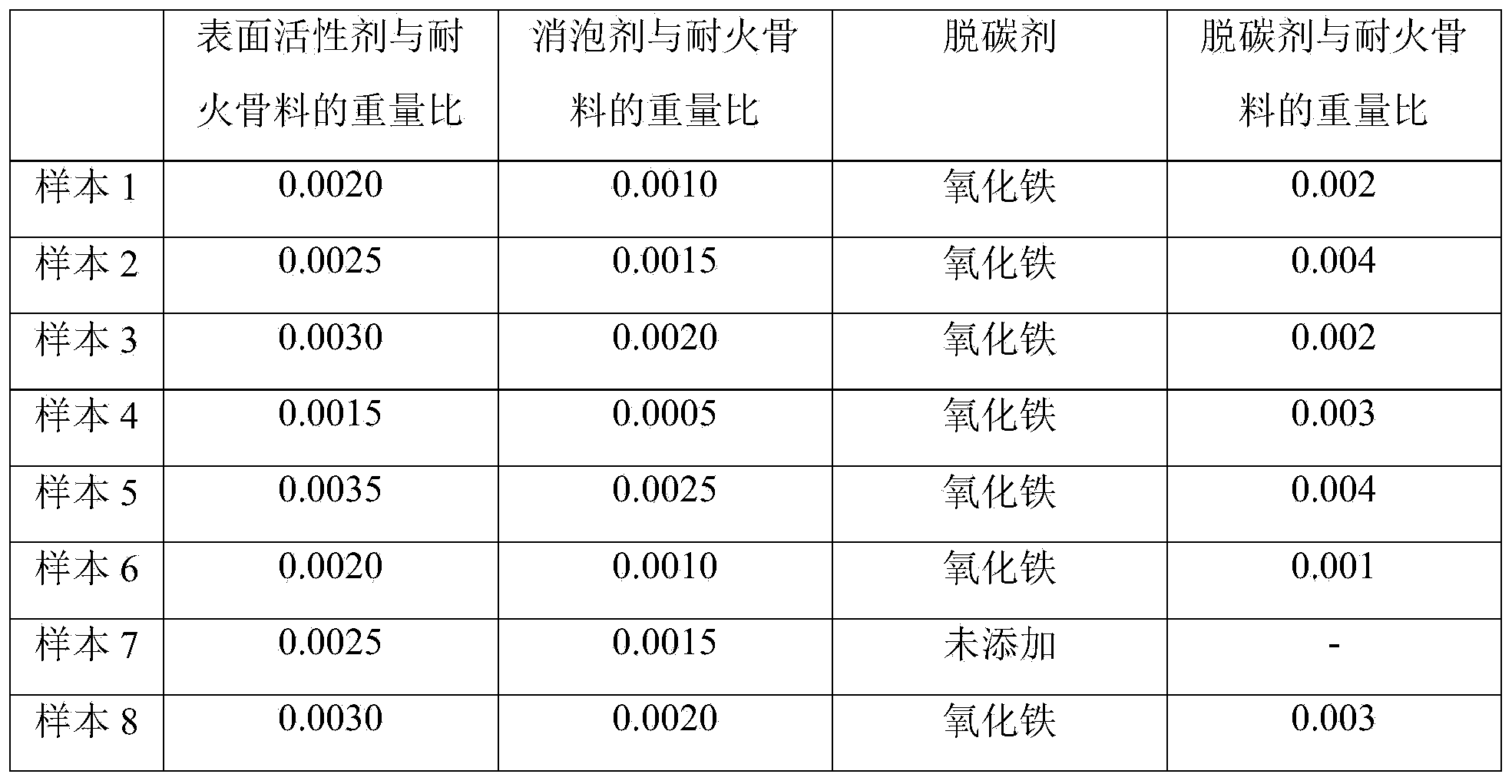

[0054] Step 3. Add binder and suspending agent to the mixture of refractory aggregate and water and stir, the type of binder in sample 1-8 and its ratio with refractory aggregate, and the suspending agent in sample 1-8 The types of the samples and their proportioning ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com