A loom upper shaft manipulator

A technology of manipulators and looms, applied in the directions of manipulators, textiles, textiles and papermaking, can solve the problems of looms that cannot be placed, unfavorable arrangement of equipment, easy to roll and fall, etc. The effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

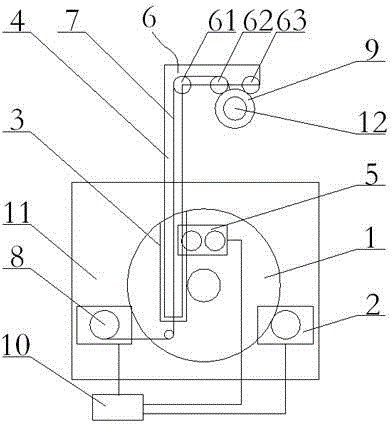

[0021] figure 1 As shown, a loom upper shaft manipulator includes a rotating seat 1, a rotating seat driving mechanism 2, a fixed slideway 3, a telescopic arm 4, a telescopic arm driving mechanism 5, a lifting pulley block 6, a reversing pulley 61, an intermediate pulley 62, a side Pulley 63, suspension rope 7, suspension rope retractable mechanism 8, ring suspension hook 9 and control electrical box 10. The two swivel seats 1 are arranged symmetrically on the left and right loom wallboards 11 on the upper part of the loom. Fixed slideway 3, the lower part of a telescopic arm 4 is installed in the fixed slideway 3, and the lower part of the telescopic arm 4 is connected with a telescopic arm drive mechanism 5 that drives the telescopic arm 4 to adjust sliding positioning along the fixed slideway 3, and the upper part of the telescopic arm 4 A sling 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com