Glass fiber reinforced polypropylene resin and preparation method thereof

A polypropylene resin and glass fiber technology, applied in the field of polypropylene resin, can solve the problems of easy warpage, rough surface, poor impact strength, etc., to improve tensile strength, heat distortion temperature, and warpage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

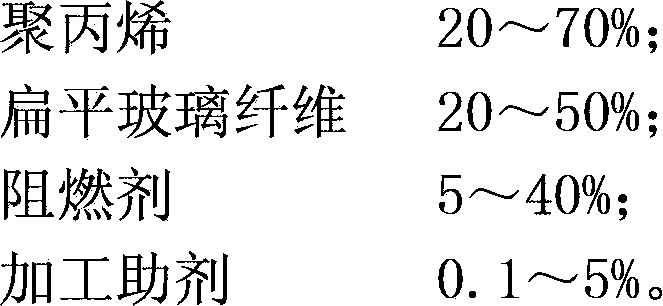

[0024] Glass fiber reinforced polypropylene resin of the present invention, by weight percentage, it comprises following components:

[0025]

[0026] Dry the polypropylene resin in an oven with a dehumidification dryer at a temperature of 90-110°C for 4-8 hours; weigh the flame retardant and processing aids and add them to a high-speed mixer for high-speed pre-mixing; mix the above steps The mixture of polypropylene, flame retardant and processing aid, and the weighed flat glass fiber are sequentially added to the twin-screw extruder to melt and extrude to pelletize. ℃, the second interval is 160-200°C, the third interval is 160-200°C, the fourth interval is 160-200°C, the fifth interval is 160-200°C, the sixth interval is 180-220°C, the seventh interval is 180-220°C, the eighth interval is 180-220°C , the nine intervals are 180-220°C, and the temperature of the machine head is 210-240°C.

Embodiment 2

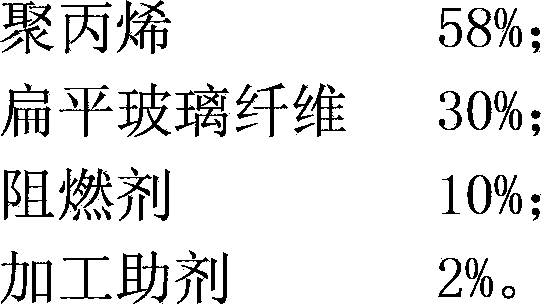

[0028] Glass fiber reinforced polypropylene resin of the present invention, by weight percentage, it comprises following components:

[0029]

[0030]

[0031] Dry the polypropylene resin in an oven with a dehumidification dryer at a temperature of 90-110°C for 4-8 hours; weigh the flame retardant and processing aids and add them to a high-speed mixer for high-speed pre-mixing; mix the above steps The mixture of polypropylene, flame retardant and processing aid, and the weighed flat glass fiber are sequentially added to the twin-screw extruder to melt and extrude to pelletize. ℃, the second interval is 160-200°C, the third interval is 160-200°C, the fourth interval is 160-200°C, the fifth interval is 160-200°C, the sixth interval is 180-220°C, the seventh interval is 180-220°C, the eighth interval is 180-220°C , the nine intervals are 180-220°C, and the temperature of the machine head is 210-240°C.

Embodiment 3

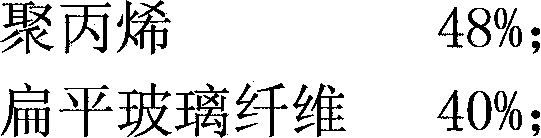

[0033] Glass fiber reinforced polypropylene resin of the present invention, by weight percentage, it comprises following components:

[0034]

[0035] Dry the polypropylene resin in an oven with a dehumidification dryer at a temperature of 90-110°C for 4-8 hours; weigh the flame retardant and processing aids and add them to a high-speed mixer for high-speed pre-mixing; mix the above steps The mixture of polypropylene, flame retardant and processing aid, and the weighed flat glass fiber are sequentially added to the twin-screw extruder to melt and extrude to pelletize. ℃, the second interval is 160-200°C, the third interval is 160-200°C, the fourth interval is 160-200°C, the fifth interval is 160-200°C, the sixth interval is 180-220°C, the seventh interval is 180-220°C, the eighth interval is 180-220°C , the nine intervals are 180-220°C, and the temperature of the machine head is 210-240°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com