A kind of anti-corrosion paint with strong anti-oxidation, anti-acid and alkali corrosion performance and preparation method thereof

An anti-corrosion coating and corrosion-resistant technology, applied in anti-corrosion coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of poor ozone corrosion resistance and complex production process, and achieve excellent aging resistance, wide temperature resistance, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

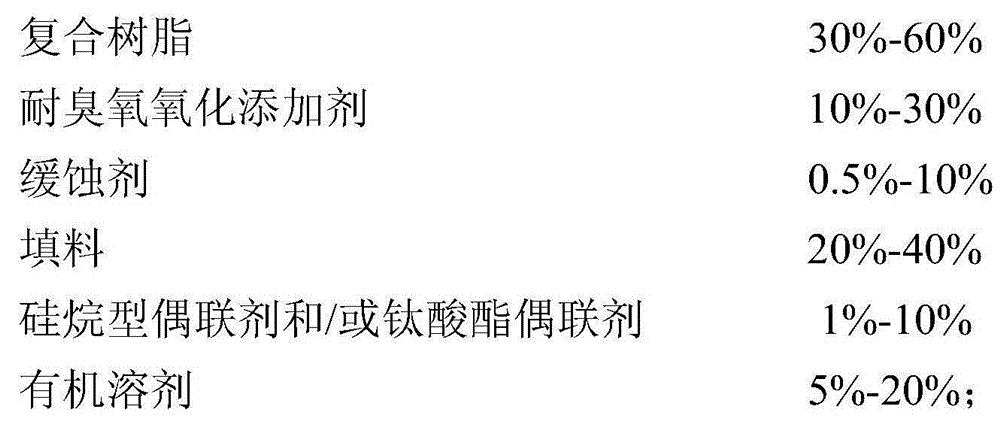

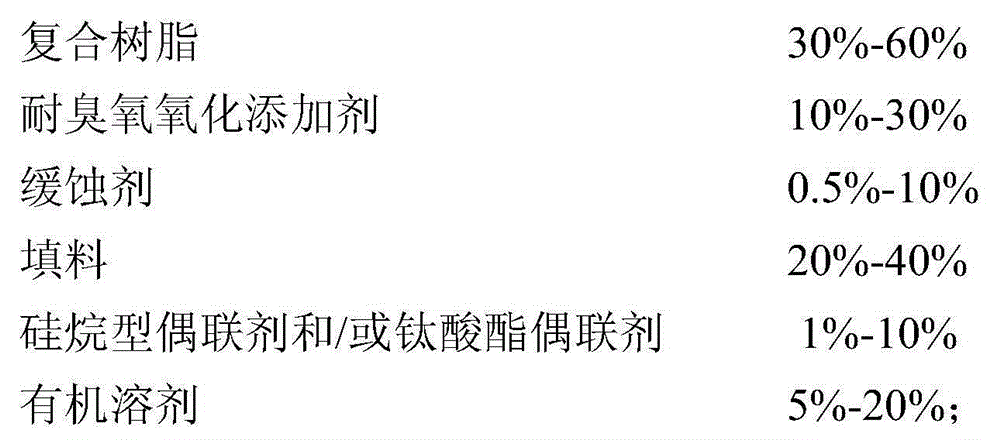

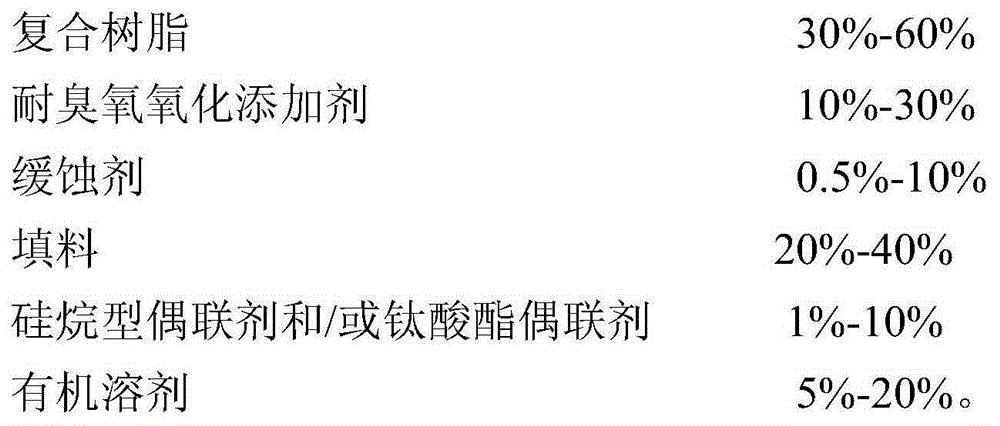

Method used

Image

Examples

Embodiment 1

[0037] Weigh 15% phenolic resin, 30% epoxy resin, 5% styrene, and 5% trichloroethylene in proportion, add them to a high-speed dispersion kettle, heat at 200°C, and stir at 500r / min for 5 hours until the dispersion is uniform.

[0038] Weigh 10% mica flakes and 15% glass flake fillers and fully grind them with a ball mill at 450r / min for 5 hours to prepare powder fillers.

[0039] Mix the prepared composite resin, powder filler, 1% polyepoxysuccinic acid, 1% benzimidazole, 10% methyl silane, 5% dibutyl tin dimonthly silicate, 1% KH570, 2% KH570 , 300r / min stirring for 4 hours until the mixture is uniform.

Embodiment 2

[0041] Weigh 10% urea-formaldehyde resin, 15% unsaturated polyester resin, 20% epoxy resin, 6% trichloroethylene and 4% ethylene glycol ether in proportion, add them to the high-speed dispersion kettle, heat at 180℃, 450r / min Stir for 5 hours until evenly dispersed.

[0042] Weigh 10% graphite flakes, 10% glass flakes, and 5% titanium dioxide fillers and grind them with a ball mill 350r / min for 5.5 hours to make powder fillers.

[0043] Press the prepared composite resin, powder filler, 0.5% polyaspartic acid, 1.5% polyepoxysuccinic acid, 5% organic hydroxy silicone, 10% organic methyl silicone, 1% KH570, 2% KH792 Proportional mixing, stirring at 350r / min for 3 hours until the mixture is uniform.

Embodiment 3

[0045] Weigh 20% urea-formaldehyde resin, 25% polyurethane, 5% ethylene glycol ether, and 5% triethanolamine into a high-speed dispersion kettle, heat at 220°C and stir at 450r / min for 5 hours until the dispersion is uniform.

[0046] Weigh 10% titanium dioxide and 15% glass flake fillers and fully grind them with a ball mill at 500r / min for 4 hours to make powder fillers.

[0047] The resin, powder filler, 0.5% benzimidazole, 1.5% dihydroimidazole, 5% organic hydroxy silicone, 5% methylsilane, 5% dibutyltin dilaurate, 1% KH560, 2% DL602 Proportional mixing, stirring at 400r / min for 4 hours until the mixture is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com