Preparation method of high-purity copper target material

A high-purity copper and target material technology, applied in the field of semiconductor sputtering, can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Since the present invention focuses on explaining the principle, the drawings are not drawn to scale.

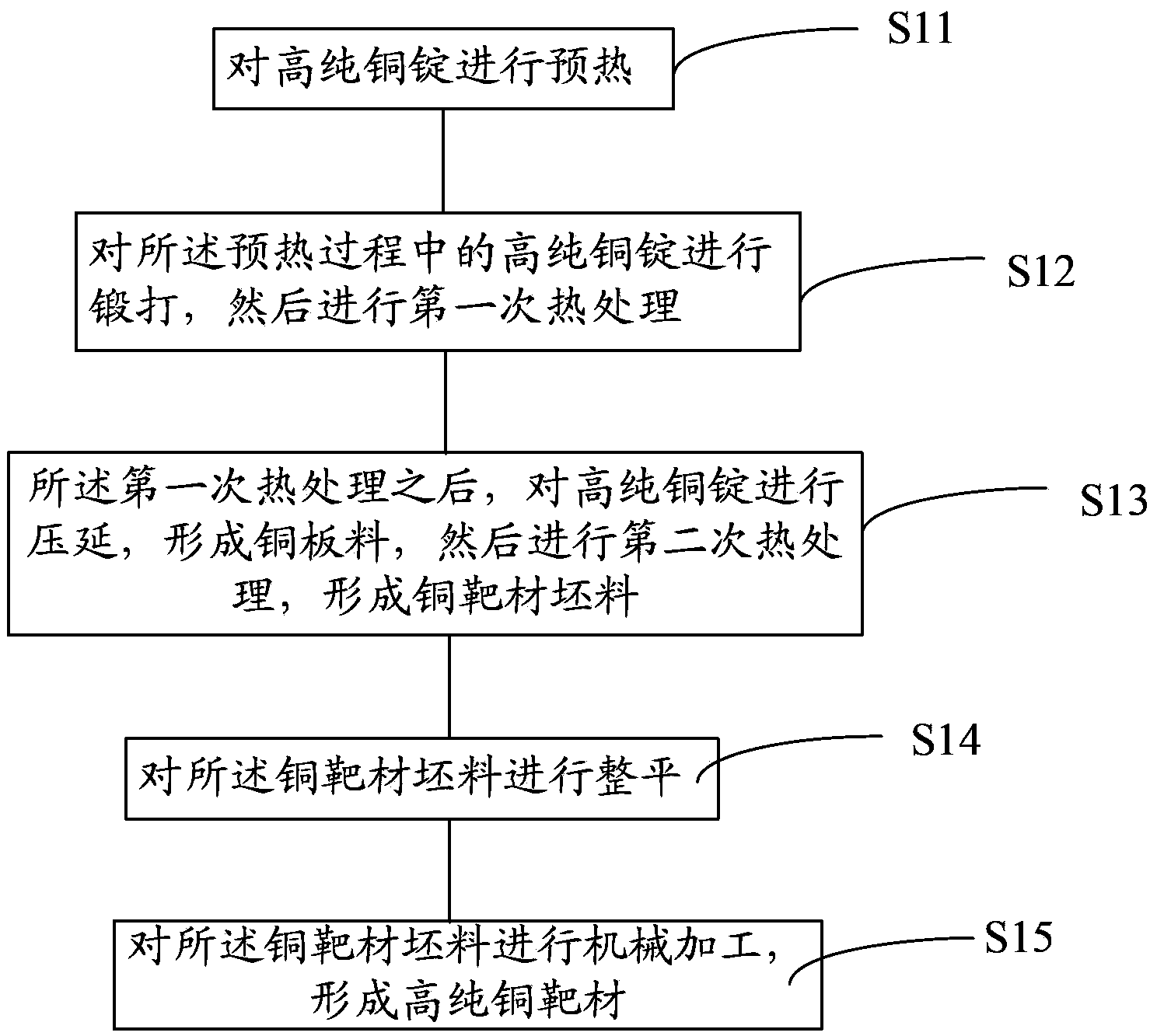

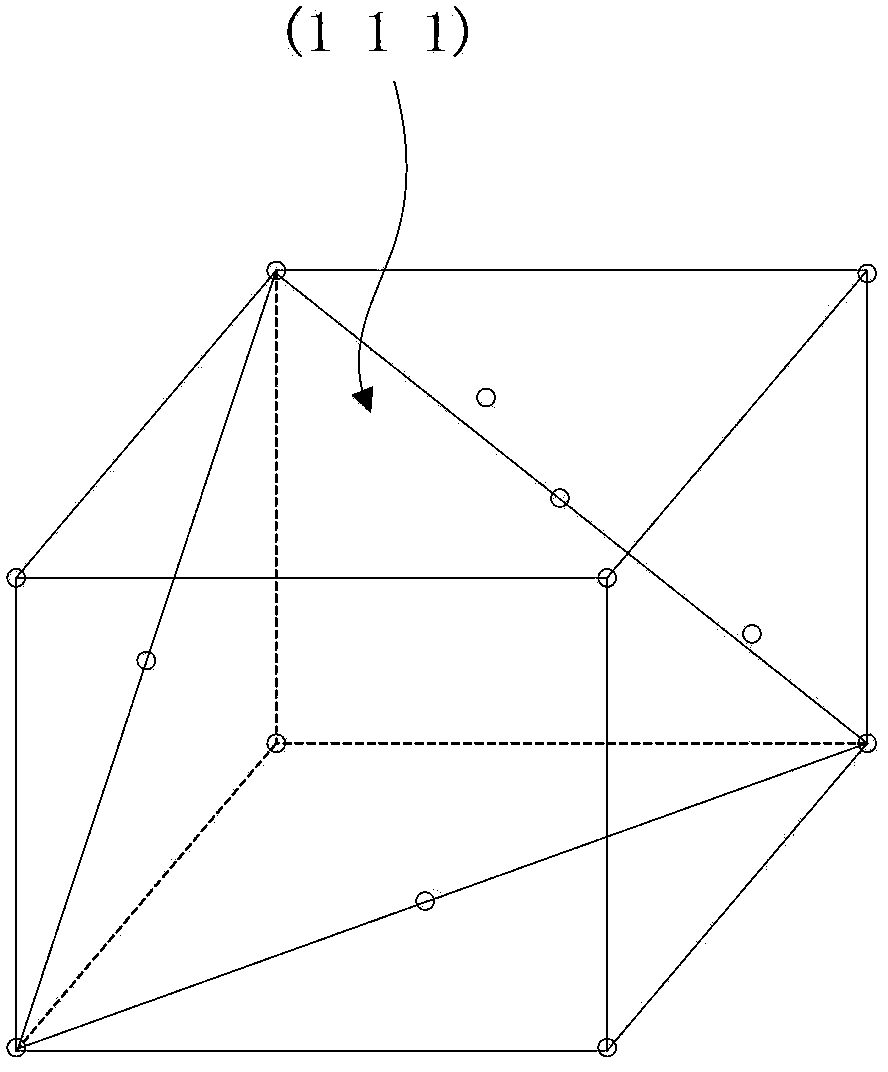

[0029] figure 1 Shown is the flow chart of the preparation method of the high-purity copper target provided by this embodiment, figure 2 for figure 1 The structure diagram corresponding to the middle forging process. The following is a specific introduction.

[0030] Step S11 is executed to preheat the high-purity copper ingot.

[0031] The general purity of the semiconductor copper target is required to be above 3N (99.99%), such as 4N5 (99.995%) or 5N (99.999%). Therefore, the purity of the high-purity copper ingot used is above 4N (99.99%), and in this embodiment, it is preferably a 4N5 (99.995%) copper ingot. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com