Concrete-filled steel tube column needle type concrete pouring construction method

The technology of steel pipe concrete and construction method is applied in the direction of construction, building structure, and construction material processing, etc. It can solve the problems of difficult selection of jacking power, injury of people when sprayed out of concrete grout, and high requirements for equipment, so as to save construction materials, Save time and labor, smooth pouring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

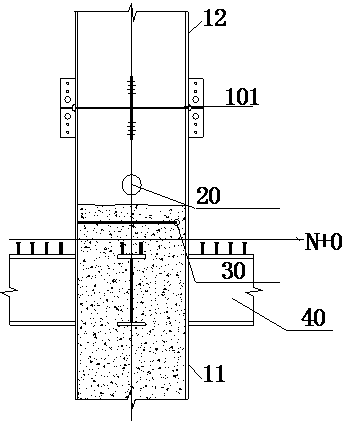

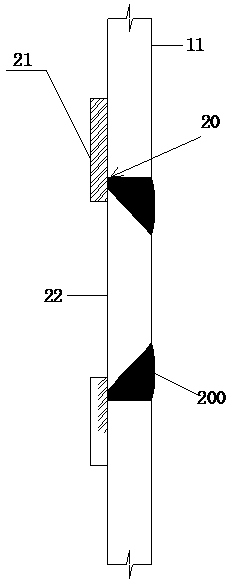

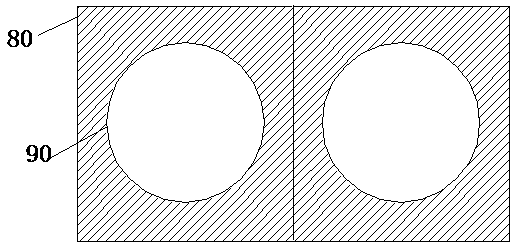

[0038] Such as figure 1 — image 3 As shown, the concrete pouring construction method of steel pipe concrete columns in this embodiment includes the following steps.

[0039] 1. Conduct concrete mix test.

[0040] Specifically, first select quality qualified raw materials, measure the temperature of the material, weigh the weight, and then add water in a certain proportion for mixing to obtain concrete. Then perform performance tests on the concrete, check the expansion and slump of the self-compacting concrete, and the emptying time of the inverted slump cylinder, and obtain the concrete mix ratio that meets the design requirements for actual construction.

[0041] 2. Carry out the minimum height pouring simulation test.

[0042] Take the first test steel pipe column with the same cross-section as the steel pipe column to be poured for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com