Centripetal joint bearing with spiral groove on internal diameter

A technology of joint bearings and spiral grooves, which is applied to bearing components, shafts and bearings, sliding contact bearings, etc., can solve the problems of low processing efficiency, easy wear and sticking of inner diameter and shaft, and less oil storage in lubricating grooves. Product quality and process efficiency, improved process operability, reduced wear and seizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

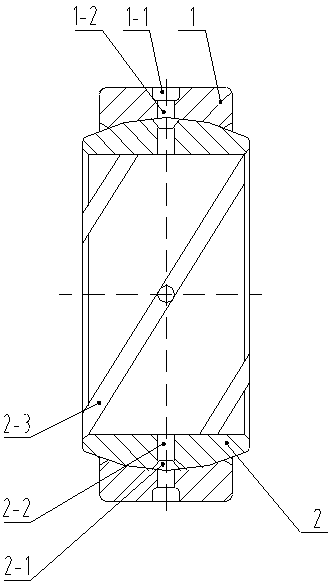

[0013] like figure 1 As shown, the present invention is composed of an outer ring 1 and an inner ring 2, the inner surface of the outer ring 1 and the outer surface of the inner ring 2 are sliding contact surfaces, the inner surface of the outer ring 1 is an inner spherical surface, the outer surface of the inner ring 2 is an outer spherical surface, and the outer surface of the outer ring 2 is an outer spherical surface. There is an annular outer ring outer diameter lubricating groove 1-1 and an outer ring lubricating oil hole 1-2 at the center of the outer diameter width of ring 1; there is an annular outer ring outside the inner ring at the center of the outer spherical surface width of inner ring 2 that is perpendicular to the center line of the inner hole. Spherical lubricating groove 2-1 and inner ring lubricating oil hole 2-2, inner ring inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com