Torque loading mechanism

A technology of torque loading and bolt loading, which is applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc. It can solve problems such as high cost of hydraulic torque loaders, inability to increase the speed of test benches, and no mature manufacturers. , to achieve the effect of compact structure, strong competitive advantage and simple structure of the test bench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with accompanying drawing:

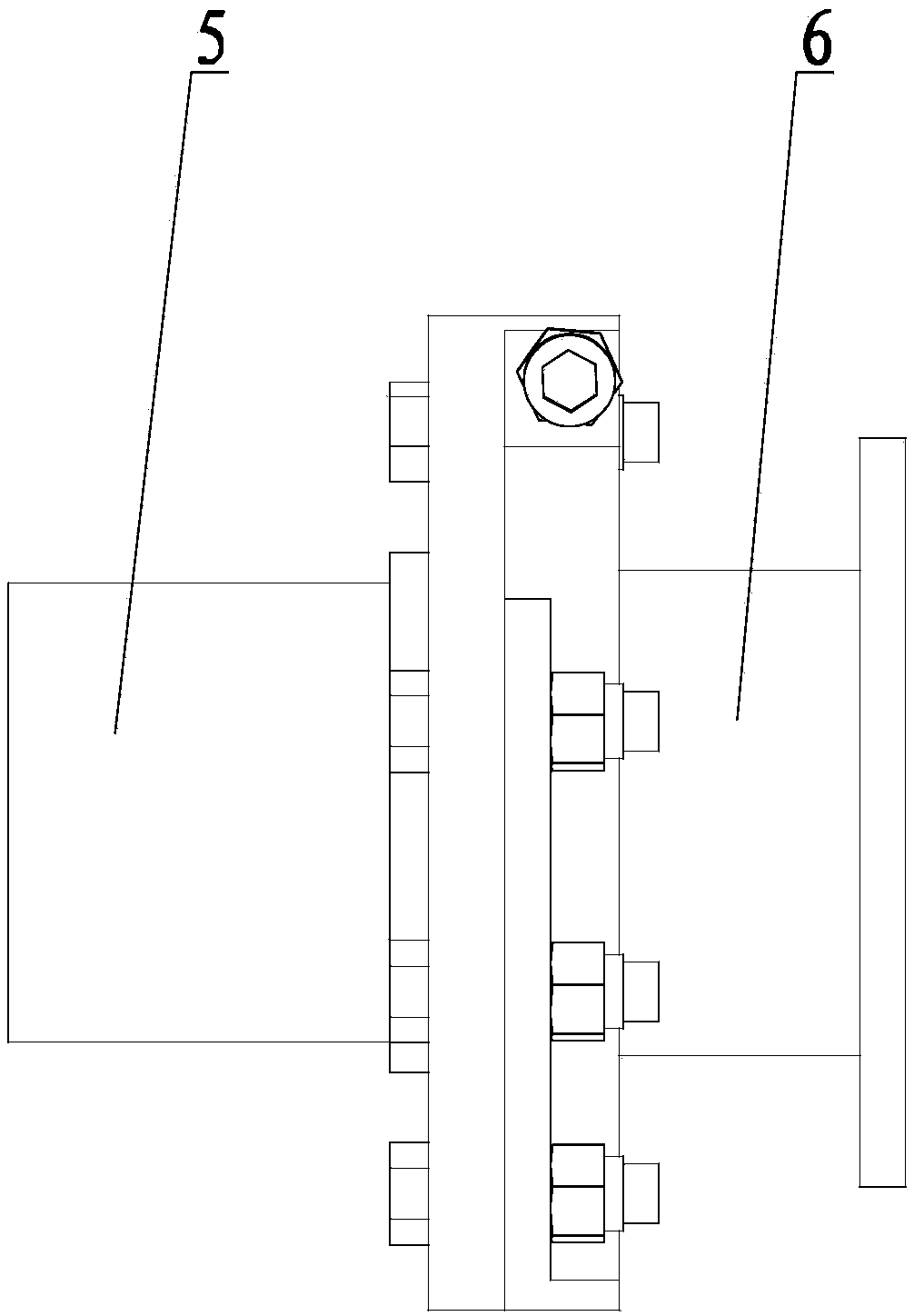

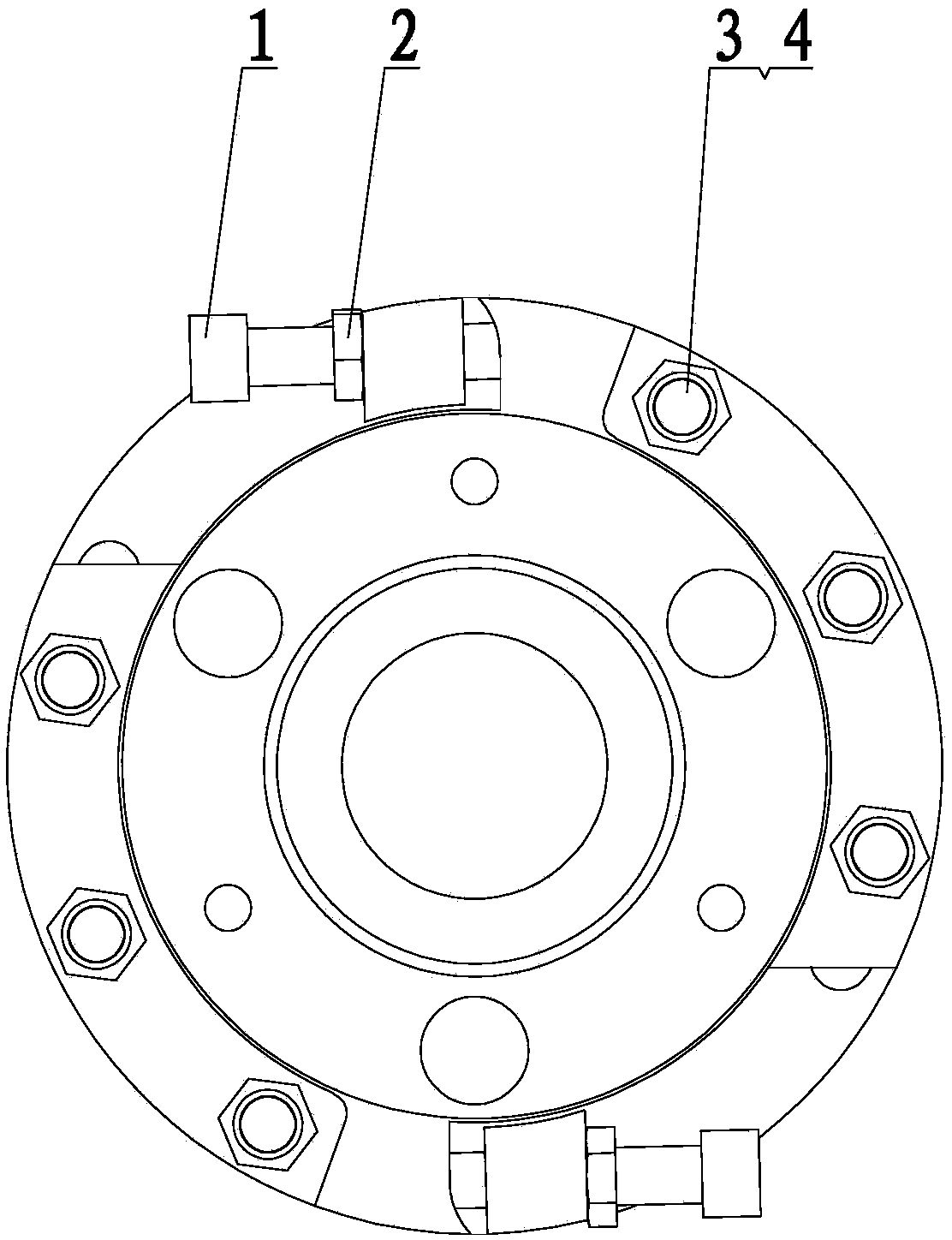

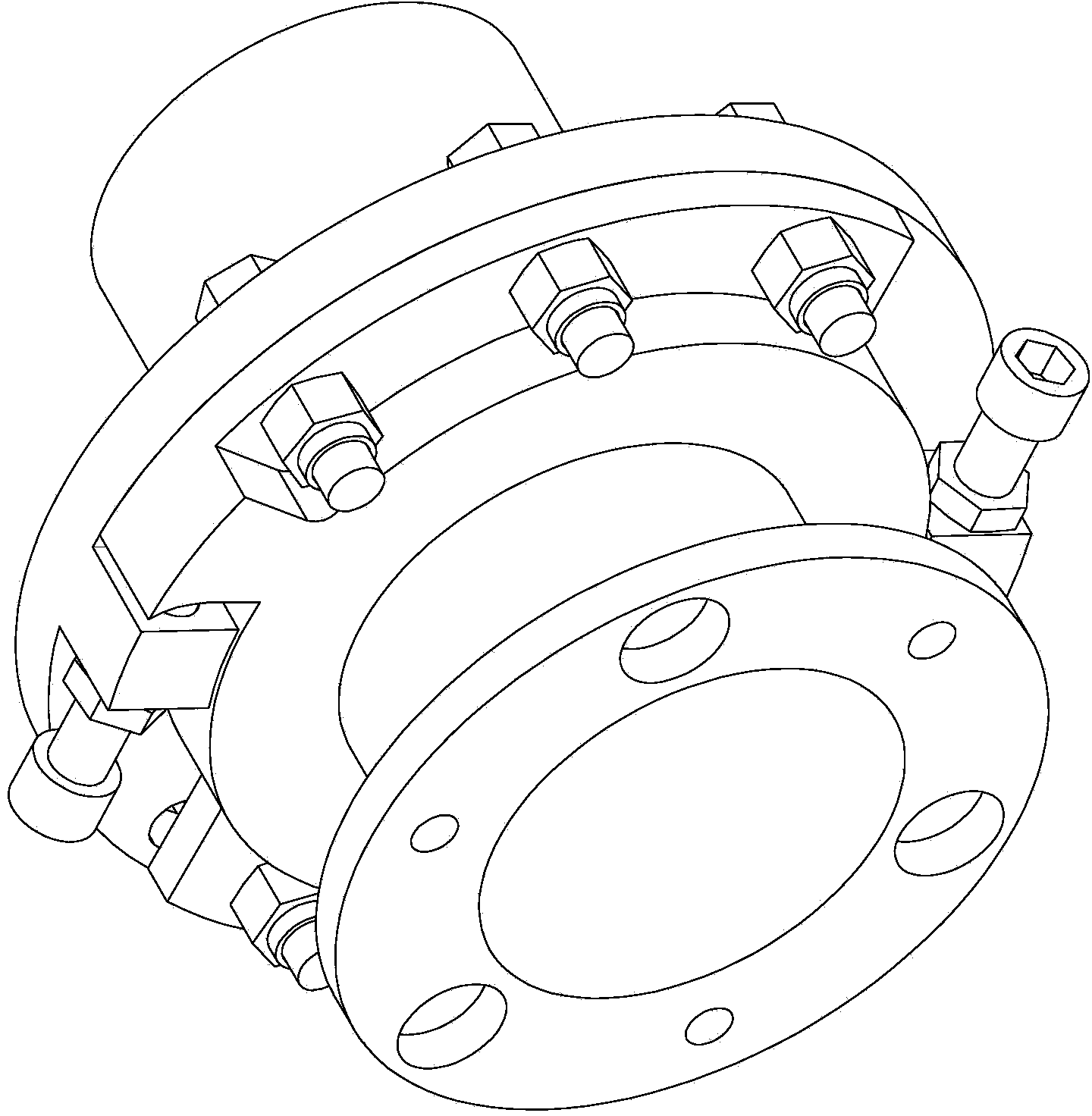

[0016] Such as Figure 1-Figure 2 As shown, it includes loading bolt 1, locking nut 2, locking bolt 3, self-locking nut 4, loading flange 5 and loading adapter plate 6.

[0017] The loading flange 5 is provided with two centrally symmetrical loading threaded holes; the loading flange 5 is provided with two groups of symmetrical arc grooves, each group of three grooves; the loading bolt 1 is connected from the loading flange 5 Tighten in the threaded hole, and put it on the loading adapter plate 6. The loading adapter plate 6 is provided with two groups of symmetrical holes, each group of three holes corresponds to the loading flange one by one; the loading flange 5 is nested with the loading adapter plate 6; locked with the lock nut 2, the loading flange 5 and the load adapter plate 6 produce an angular displacement, and the torque is observed through the torque sensor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com