Filter support

A technology of filters and mirror clips, which is applied in installation, optics, instruments, etc., can solve problems such as unfavorable outdoor use, inability to enter light vertically, troublesome installation, etc., and achieve convenient and quick installation and adjustment, small light dimming effect, Effect to prevent entrance of stray light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

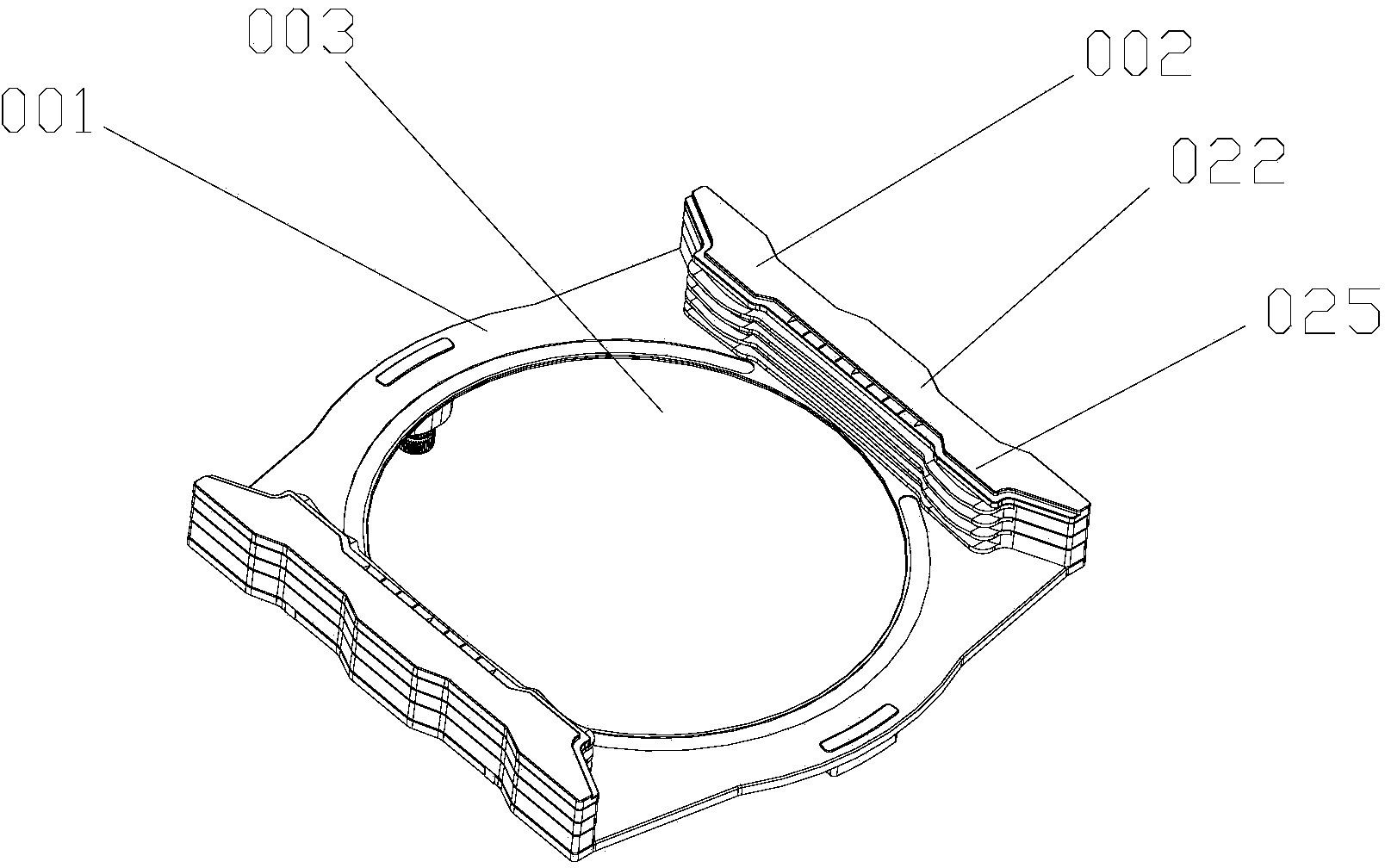

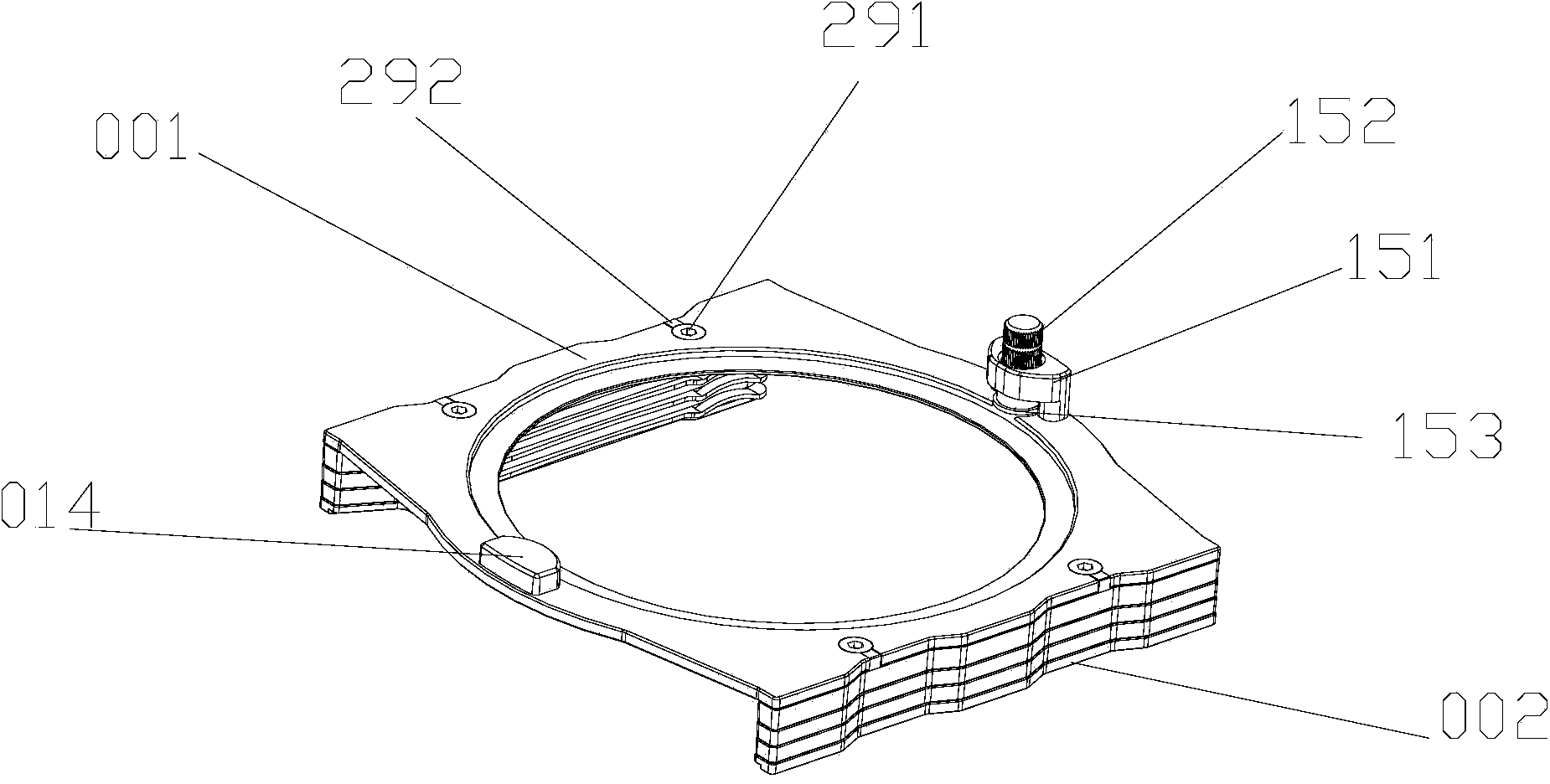

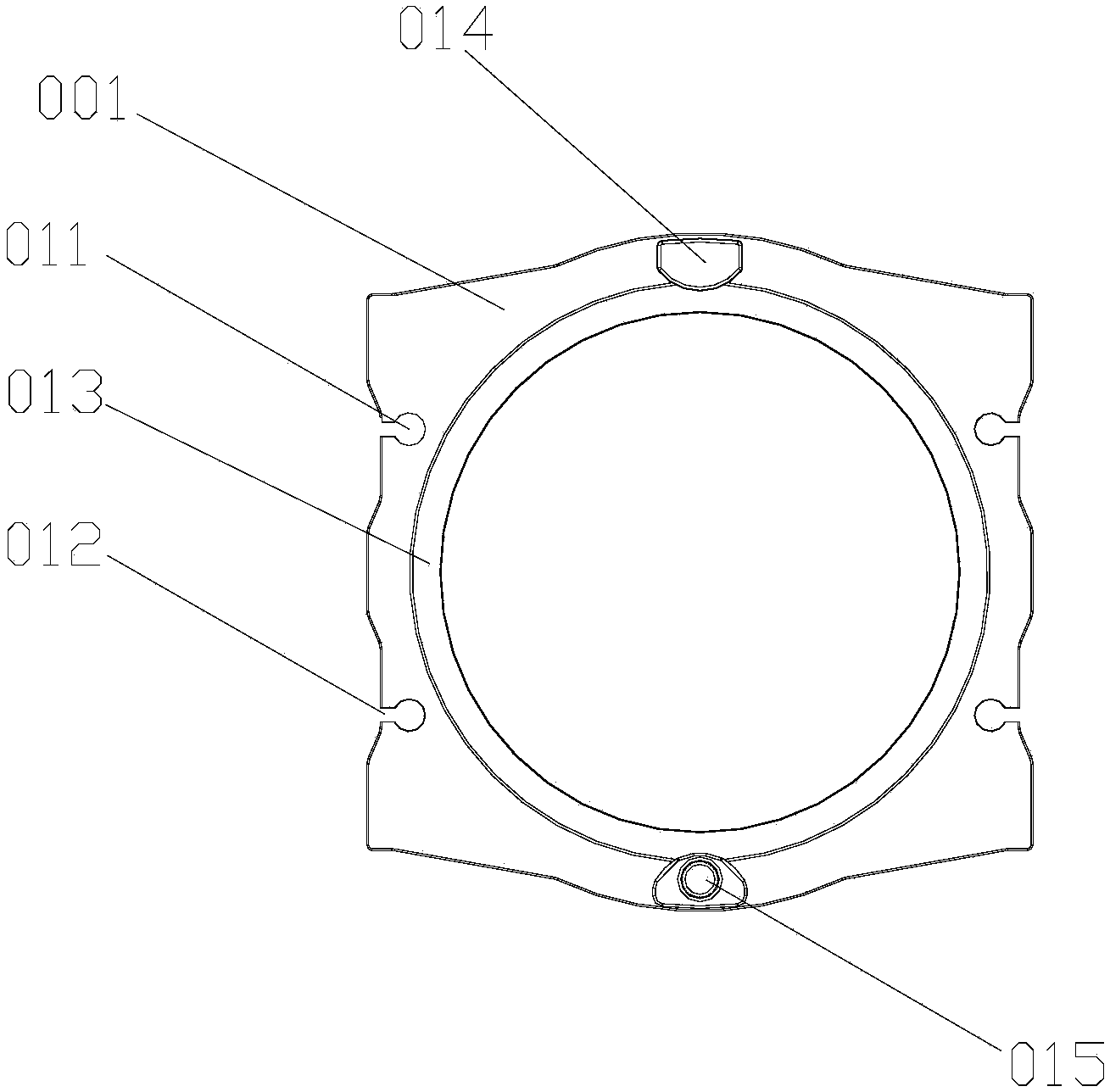

[0024] figure 1 A filter holder according to the invention is schematically shown.

[0025] According to one aspect of the present invention, a filter holder is provided, such as figure 1 Shown includes the bracket body 001 and the mirror clip 002 installed on the bracket body 001:

[0026] The bracket body 001 is integrally formed by precision machining of 6061T aluminum alloy. It has a square structure as a whole, and hard anodized treatment is performed on its surface to form a hard oxide film layer. The use of 6061T aluminum alloy ensures the support strength of the bracket body 001 while ensuring the pressure resistance, wear resistance and low temperature resistance of the bracket body 001. It will not be deformed after long-term use. A hard oxide film layer is set on the surface to increase the wear resistance of the surface degree, thereby increasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com