Ballastless track designing, checking and calculating system based on space detail solid model

A ballastless track and solid model technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems that the calculation accuracy of internal force cannot be guaranteed, and the design requirements cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

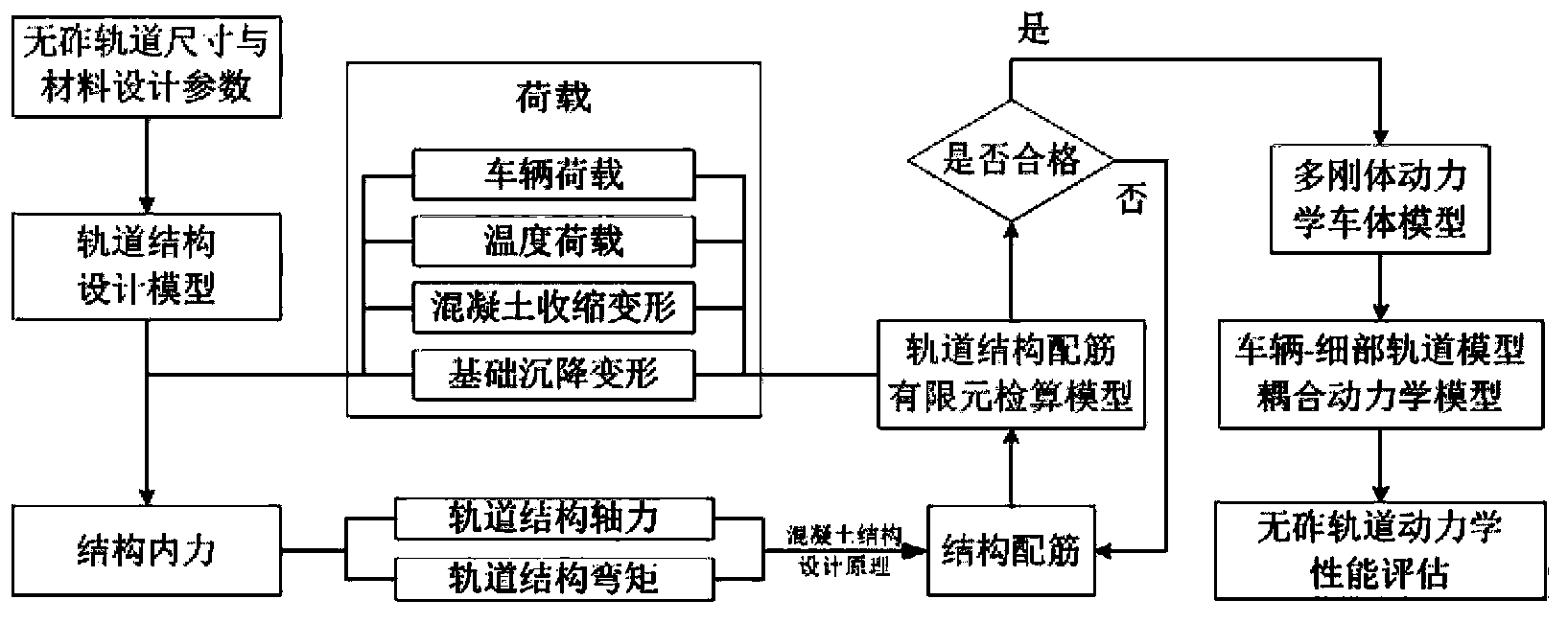

[0084] This embodiment is the design and calculation of the ballastless track of the station line, the design method of the ballastless track of the station line is as follows figure 2 shown.

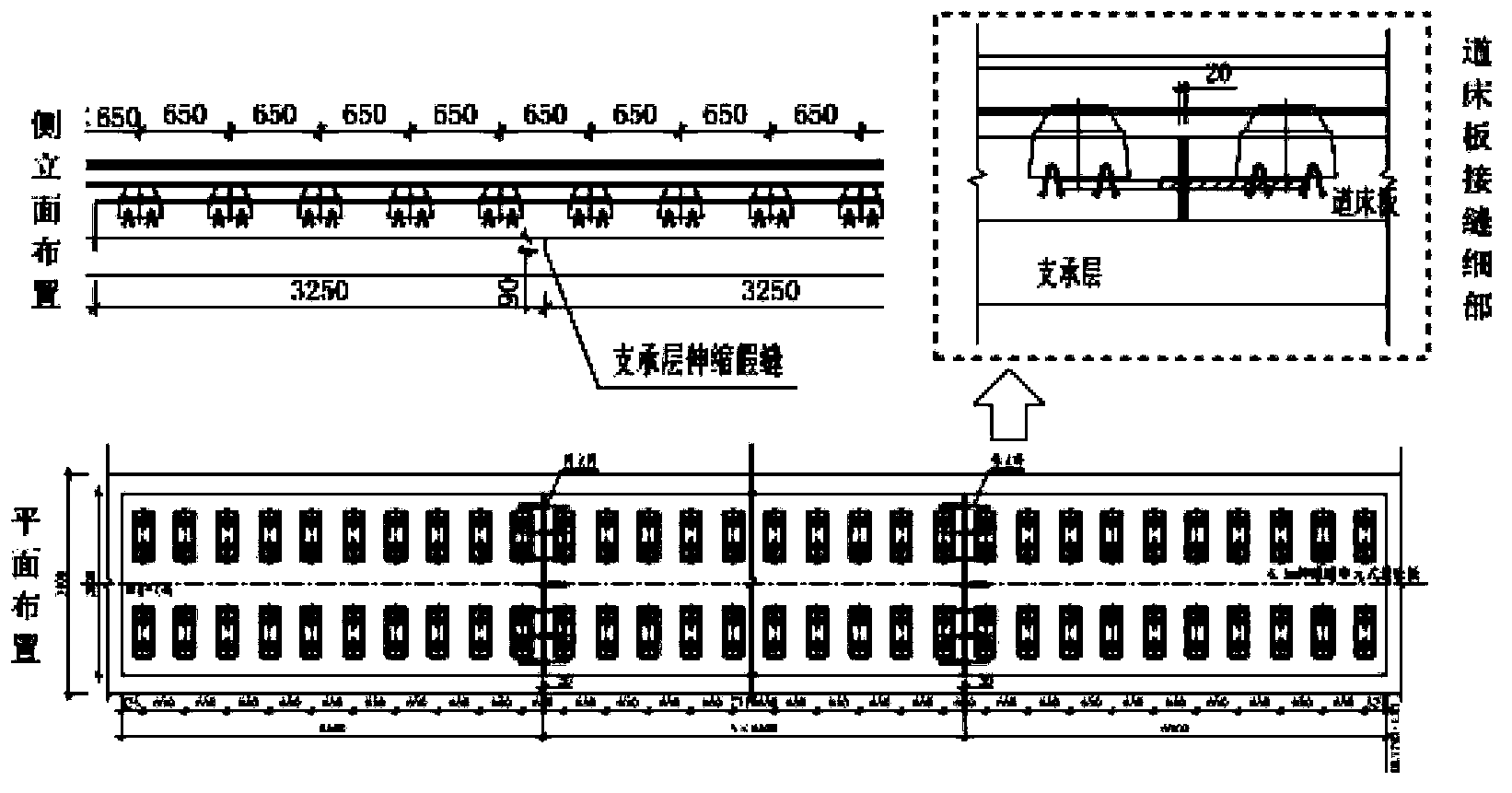

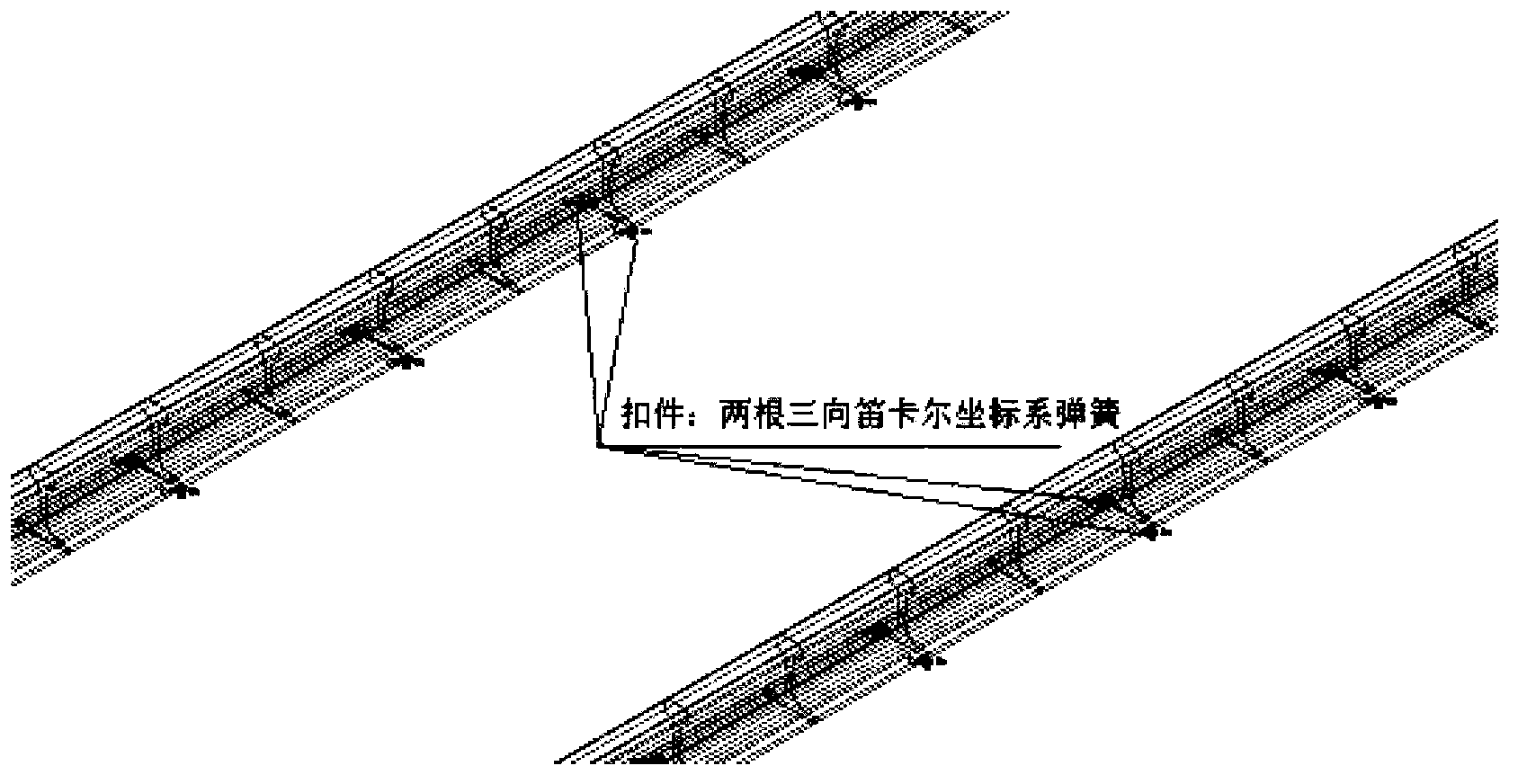

[0085] In the design model, the solid model of the rail is established, and the fastener is simulated by two three-way springs in the Cartesian coordinate system, such as image 3 shown. Both the ballast bed slab and the supporting layer are considered as solid units, and the subgrade springs are evenly distributed under the supporting layer. The spring stiffness is 76MPa / m according to the "Code for Design of High-Speed Railways (Trial)" and the theoretical results of ballastless track re-innovation. The subgrade spring model is as follows: Figure 4 As shown, the overall model of the track structure is as follows Figure 5 shown.

[0086] The loads applied in the design and calculation include temperature loads, vehicle loads, self-weight loads, concrete shrinkage deformation, fou...

Embodiment 2

[0102] In this embodiment, the static and dynamic design and calculation are carried out for the prestressed ladder track structure. Ladder-type track is a kind of frame-type ballastless track, which is mainly used in the vibration reduction section of urban rail transit. The layout of the ladder track is as follows Figure 13 shown.

[0103] The ladder-type track longitudinal beam is a prefabricated prestressed reinforced concrete structure with a length of 6.15m, a width of 0.46m, and a thickness of 0.185m. The material is C60 concrete. The ladder-type track steel pipe is used to connect two longitudinal beams to make it a whole. The length of the steel pipe is 1.85m, and the cross-sectional size is 0.125×0.075m. Vertical, horizontal and vertical elastic buffers and anti-vibration materials are arranged around the ladder track to transmit the vibration of the track structure to the surroundings. The finite element model obtained according to the above design parameters is...

Embodiment 3

[0125] This embodiment mainly introduces the application of this introduction method in the detailed checking model. Taking the application and inspection of CRTSⅢ slab ballastless track as an example, the application of this method in detailed inspection is introduced. Among them, the following two calculations are mainly carried out: 1) Analysis of the influence of different reinforcement methods on the base plate on the force of the base plate; 2) The strength check of the door-shaped steel bars connected to the bottom of the track slab and the self-compacting concrete.

[0126] CRTSⅢ slab ballastless track consists of rails, fasteners, track plates, door steel bars, self-compacting concrete, isolation layer, rubber cushion, base plate, etc. from top to bottom. The rail is CHN60 rail, the fastener is WJ-8 type fastener system, the distance between fasteners is 0.63m, the longitudinal force provided by each group of fasteners is 9.0kN, the transverse static stiffness is 50kN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com