Wafer transmission system

A chip transmission system and chip technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of time and cost waste, affecting the production process yield, aging and wear of transmission components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The possible implementation of the wafer transfer system of the present invention will be described below through the embodiments and accompanying drawings.

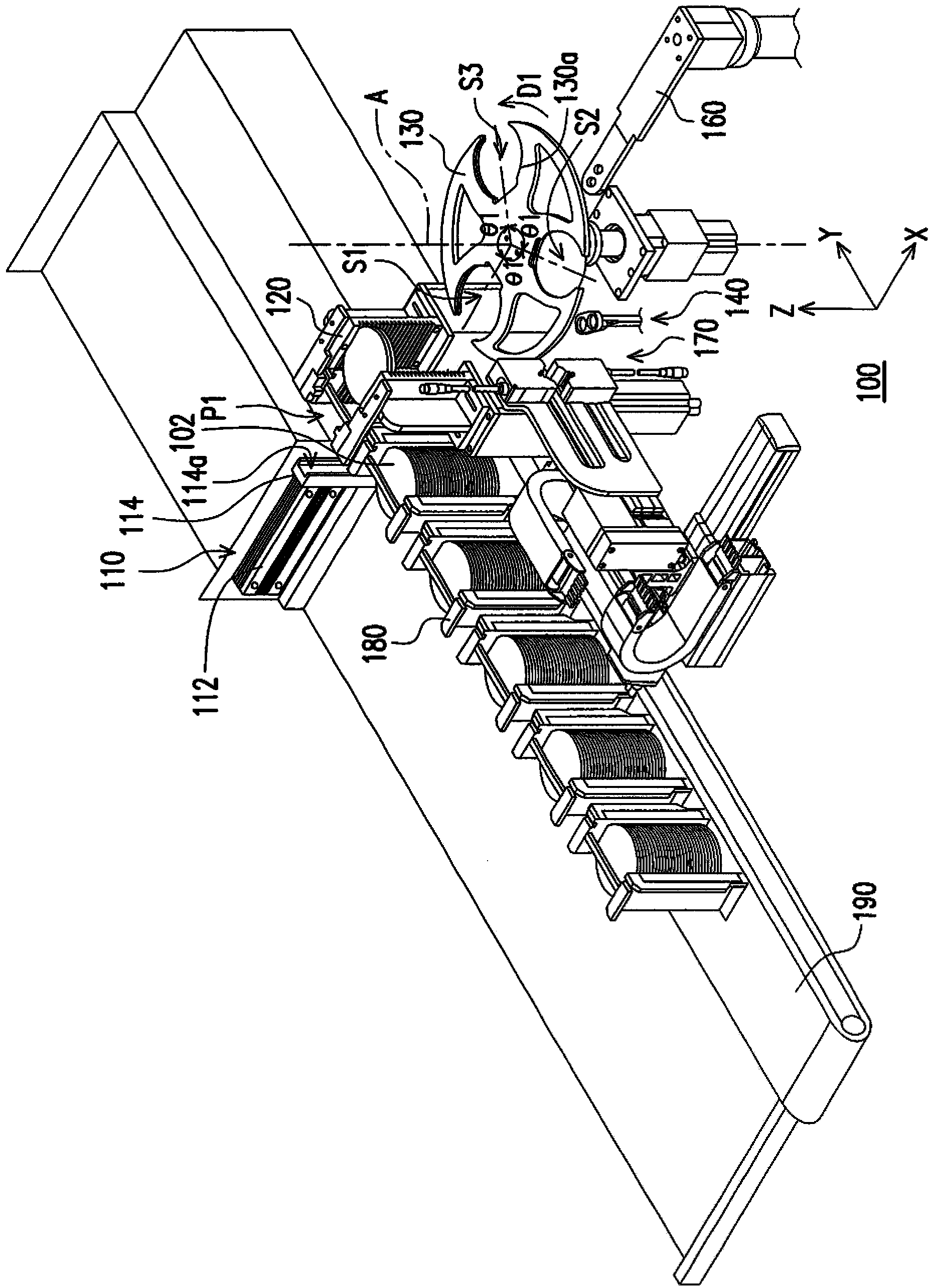

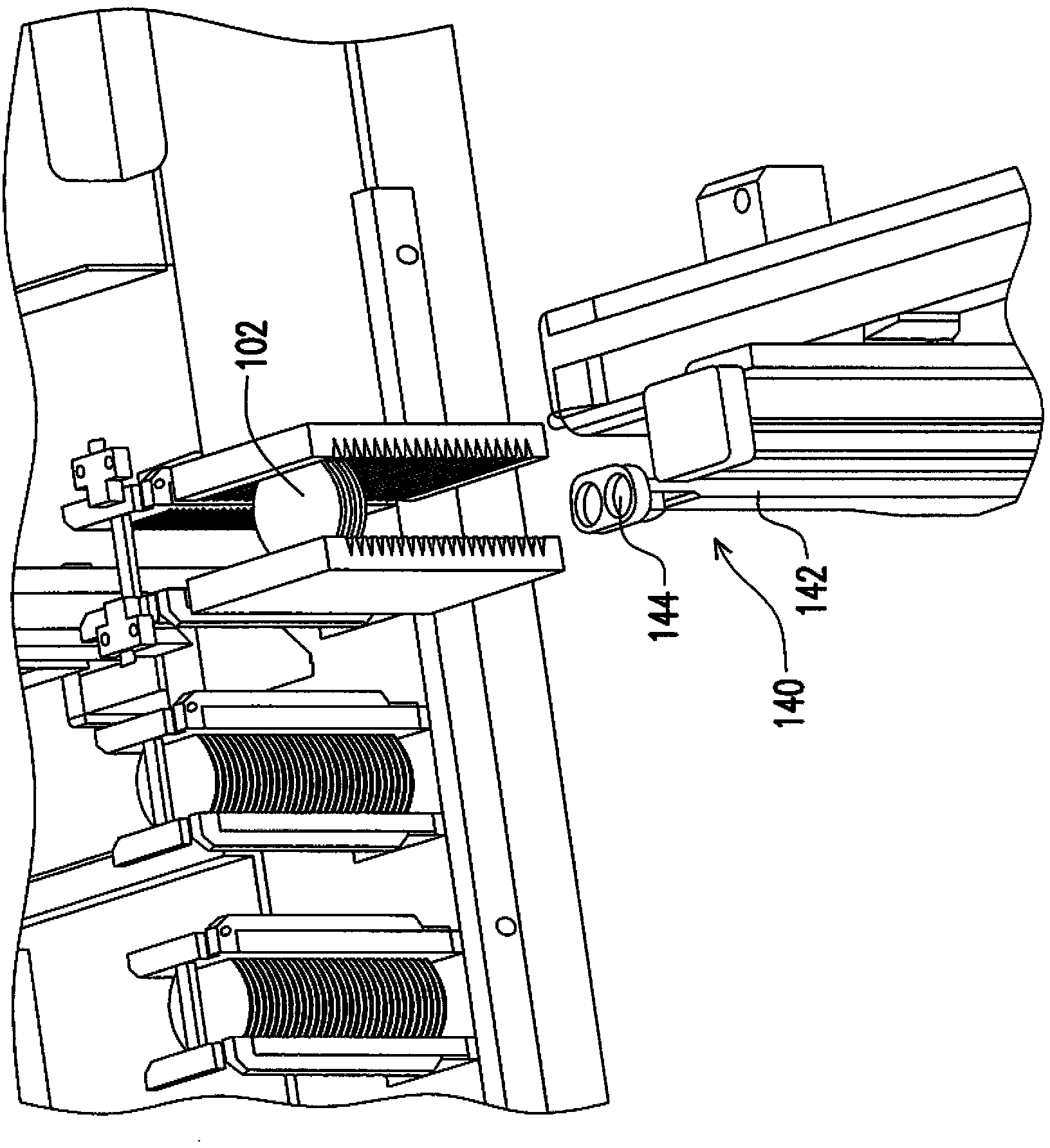

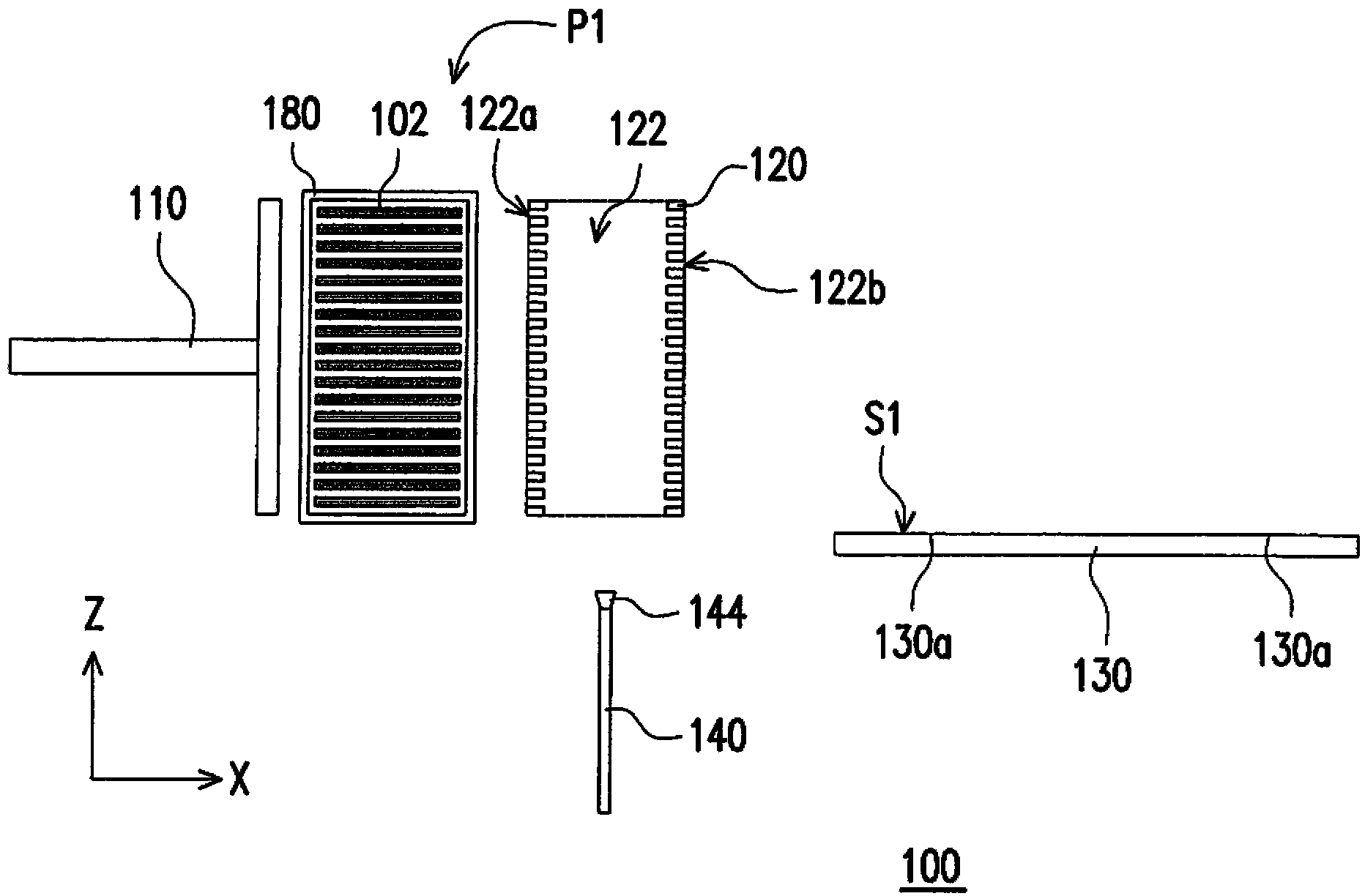

[0052] figure 1 A wafer transfer system 100 according to an embodiment of the present invention is shown. figure 2 This is a partially enlarged view of the wafer transport system 100 . The wafer transfer system 100 of this embodiment includes a feeding mechanism 110 , a positioning jig 120 , a carrying unit 130 and a pick-and-place unit 140 . figure 2 The enlarged view of FIG. 2 omits the carrying unit 130 to clearly show the pick-and-place unit 140 located below the carrying unit 130 .

[0053] The wafer transfer system 100 of the present embodiment can be applied in semiconductor manufacturing process to transfer the wafer 102 between various manufacturing process reaction chambers. Usually, the wafers 102 are stored in the wafer cassette 180, and the wafers 102 are taken out from the wafer cassette 180 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com