Optimization energy-saving dedusting control method and system of cloth bag pulse dust collector

A pulse dust collector and control system technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high hardware and software costs, difficult promotion, and huge system, and achieve high dust removal efficiency and optimized control methods , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

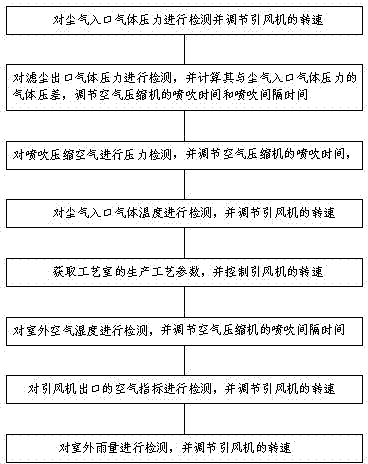

[0034] An optimized energy-saving and dust-removal control method for a bag pulse dust collector according to the present invention uses a dust removal control system to optimize energy-saving control for the bag pulse dust collector.

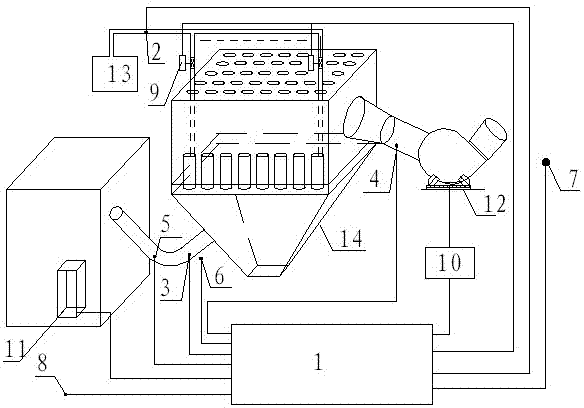

[0035] Such as figure 1 As shown, the optimized energy-saving dust removal control system of the bag pulse dust collector includes a main control system 1 and a first pressure sensor 2, a second pressure sensor 3, a third pressure sensor 4, and a temperature sensor respectively connected to the main control system 1 5. Humidity sensor 6, air detector 7, rain sensor 8, pulse control valve 9 and frequency converter 10, the main control system 1 is electrically connected with the control system 11 of the process room, and the pulse control valve 9 is arranged on the compressed air In the pipeline, the frequency converter 10 is connected to the main control system 1 and the induced draft fan 12 respectively.

[0036] The first pressure sensor 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com