Fine temperature control environment-friendly fuse machine

A hot-melting machine and sophisticated technology, applied in the direction of using electric means for temperature control, auxiliary controller with auxiliary heating device, etc., can solve the problems of insufficient energy reduction, environmental protection, high energy consumption, endangering the life and health of operators, etc. To achieve the effect of reducing energy consumption and preventing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be specifically introduced with reference to the drawings and specific embodiments.

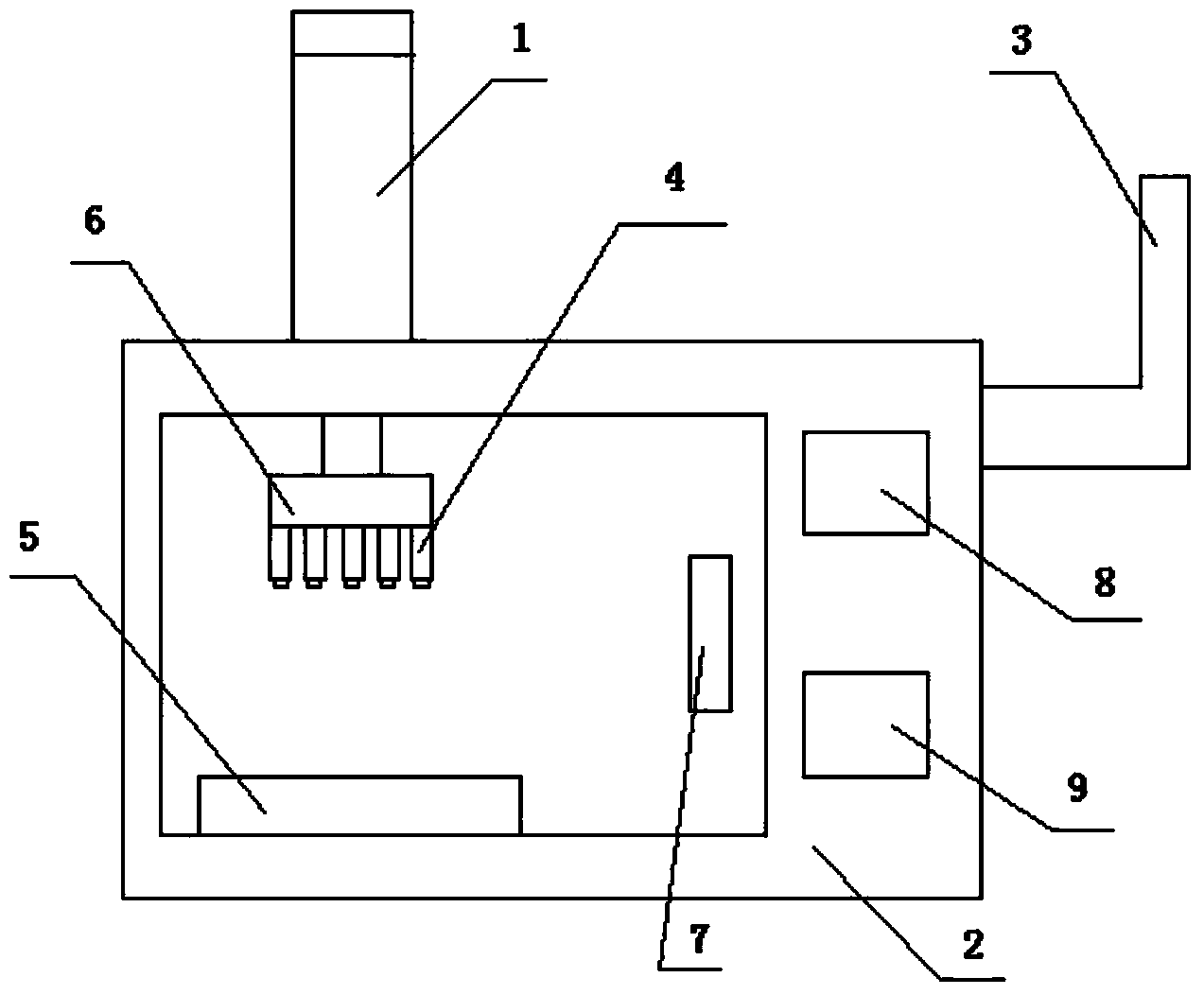

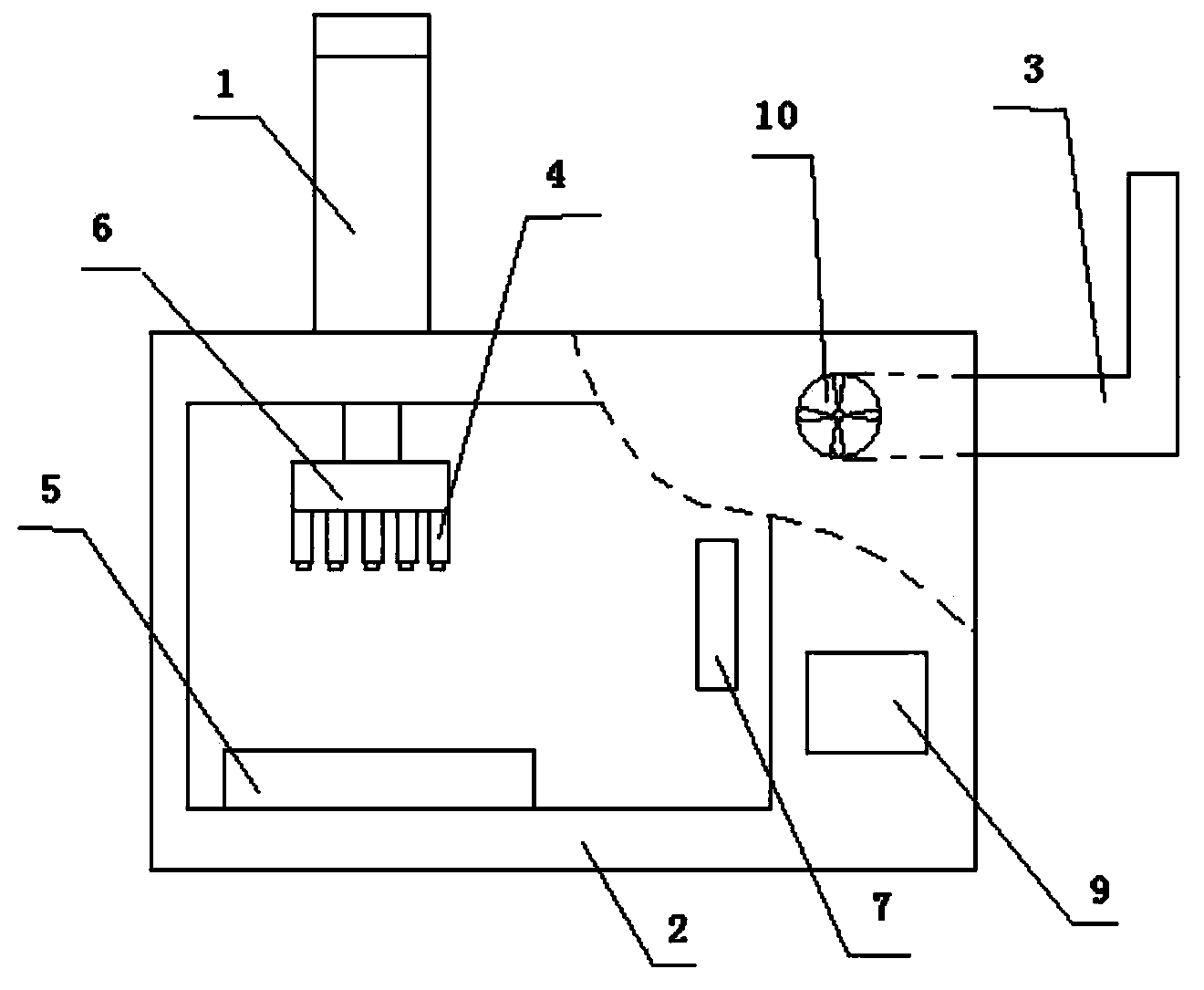

[0015] Combine figure 1 , A fine temperature control environmental protection hot melt machine, including a fuselage 2. The fuselage 2 is provided with a product workbench 5 and a hot melt device 6. The hot melt device 6 is located above the product workbench 5, and the top of the fuselage 2 is provided There is a power device 1. The power device 1 can drive the hot melt device 6 to move up and down corresponding to the product table; the fuselage 2 is also equipped with an exhaust port, which is connected with the exhaust pipe 3, which can remove harmful gases The front of the fuselage is also equipped with a temperature input device 9, which can input temperature control signals to the temperature control device inside the fuselage, and through the temperature sensing on the hot melt head 4 of the hot melt device 6 The device achieves the purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com