Device and method preventing wet sand from adhering

A moisture-proof and wet-sand technology, which is applied to cleaning devices, transportation and packaging, and conveyor objects, can solve problems affecting equipment operation efficiency and reliability, affecting the fluidity of wet sand materials, time-consuming and labor-intensive problems, etc., to achieve improved efficiency. High transport efficiency and dryer drying efficiency, extended reliability and service life, and good anti-clogging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

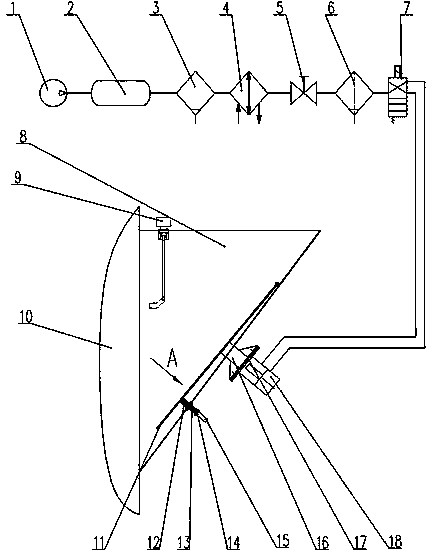

[0014] refer to figure 1 Among them, the present invention includes a vibration device, a pneumatic system, a vibration damping device and a clogging detector (9). The vibration device includes a vibrator (18), a vibrator base (17) and a vibrating rod (16), wherein the vibrator base (17) is fixed on the bottom plate of the bucket elevator feed hopper (8), and the vibrating rod (16) is fixed on the vibrating tongue (11). The installation position of the vibrating device is: make the center line of the vibrating rod (16) vertically intersect with the longitudinal center line of the vibrating tongue (11), and keep a distance of 300~320mm from the hinge point at the upper end of the vibrating tongue (11).

[0015] The pneumatic system includes air compressor (1), air storage tank (2), oil-water separator (3), cooler (4), ball valve (5), filter (6), solenoid valve (7) and other pneumatic components. The pneumatic components are connected and communicated through air pipes; the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com