Accurate PEG (polyethylene glycol) liquid pumping device

A pumping device and precise technology, which is applied in the direction of liquid distribution, transportation or transfer device, distribution device, special distribution device, etc., can solve the problem of low precision of PEG liquid pumping volume, different operation stability and accuracy, unfavorable Standardize production and other issues to achieve the effect of shortening the dosing time, avoiding human operation errors, and reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

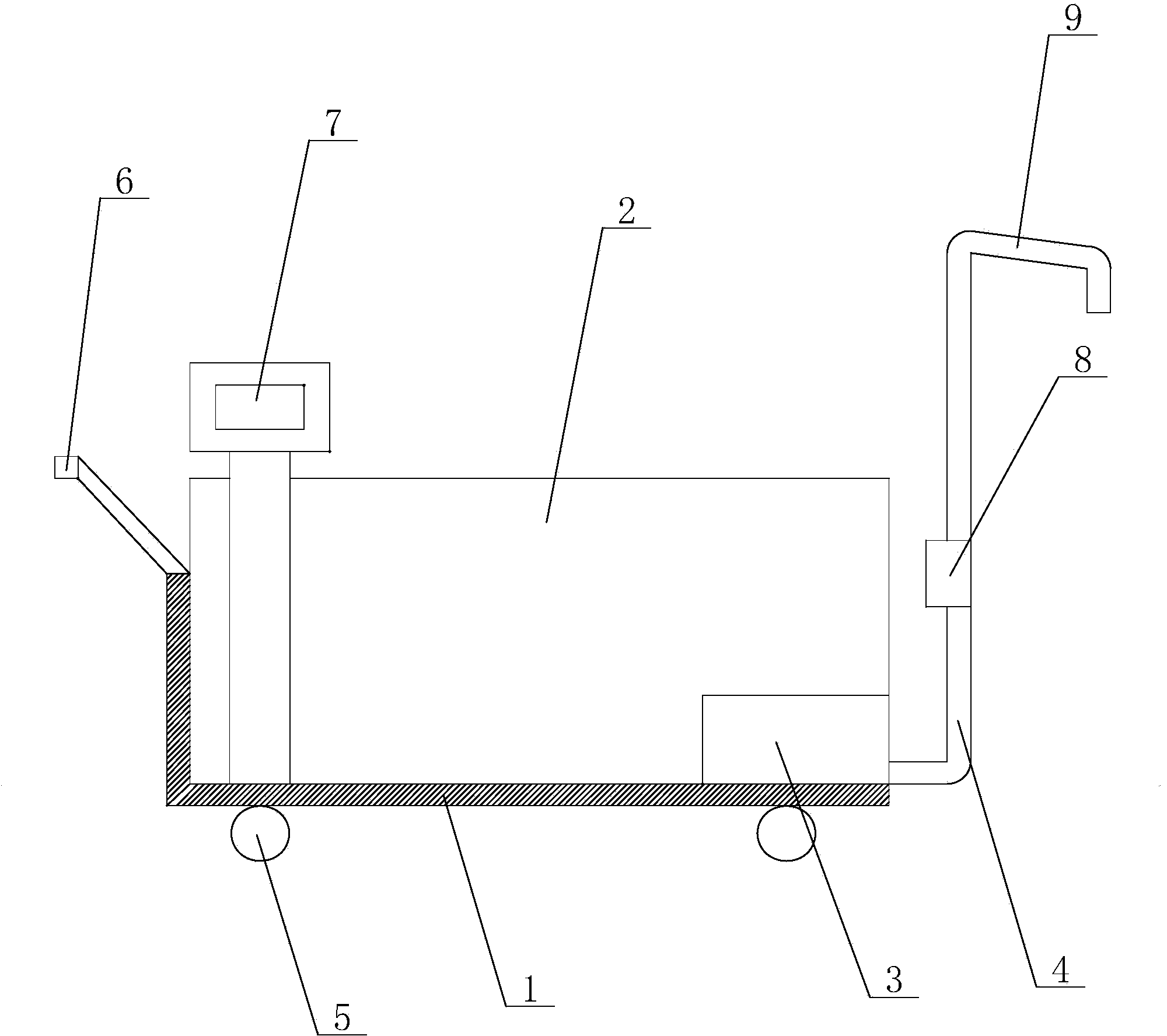

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0013] see figure 1 as shown, figure 1 It is a schematic structural diagram of the PEG liquid precision pumping device provided in Embodiment 1 of the present invention.

[0014] In this embodiment, a precise pumping device for PEG liquid includes a car body 1, a liquid storage tank 2, an electric water pump 3 and a liquid outlet pipeline 4, the bottom of the car body 1 is equipped with a walking wheel 5, and one end of the car body is equipped with a Handle 6, to facilitate the movement of the car body 1, a controller 7 is installed on one side of the car body 1, so as to facilitate manual operation, the liquid storage tank 2 is arranged on the car body 1, and the liquid storage tank An electric water pump 3 is installed at the bottom of one end of 2, and the liquid outlet end of the electric wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com