Self-mixing type anaerobic ammonia oxidation baffle plate reactor

A baffled reactor and anaerobic ammonium oxidation technology, applied in anaerobic digestion treatment and other directions, can solve the problems of starvation and lack of microorganisms, and achieve the effect of enhancing stability and excavating effective reaction volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

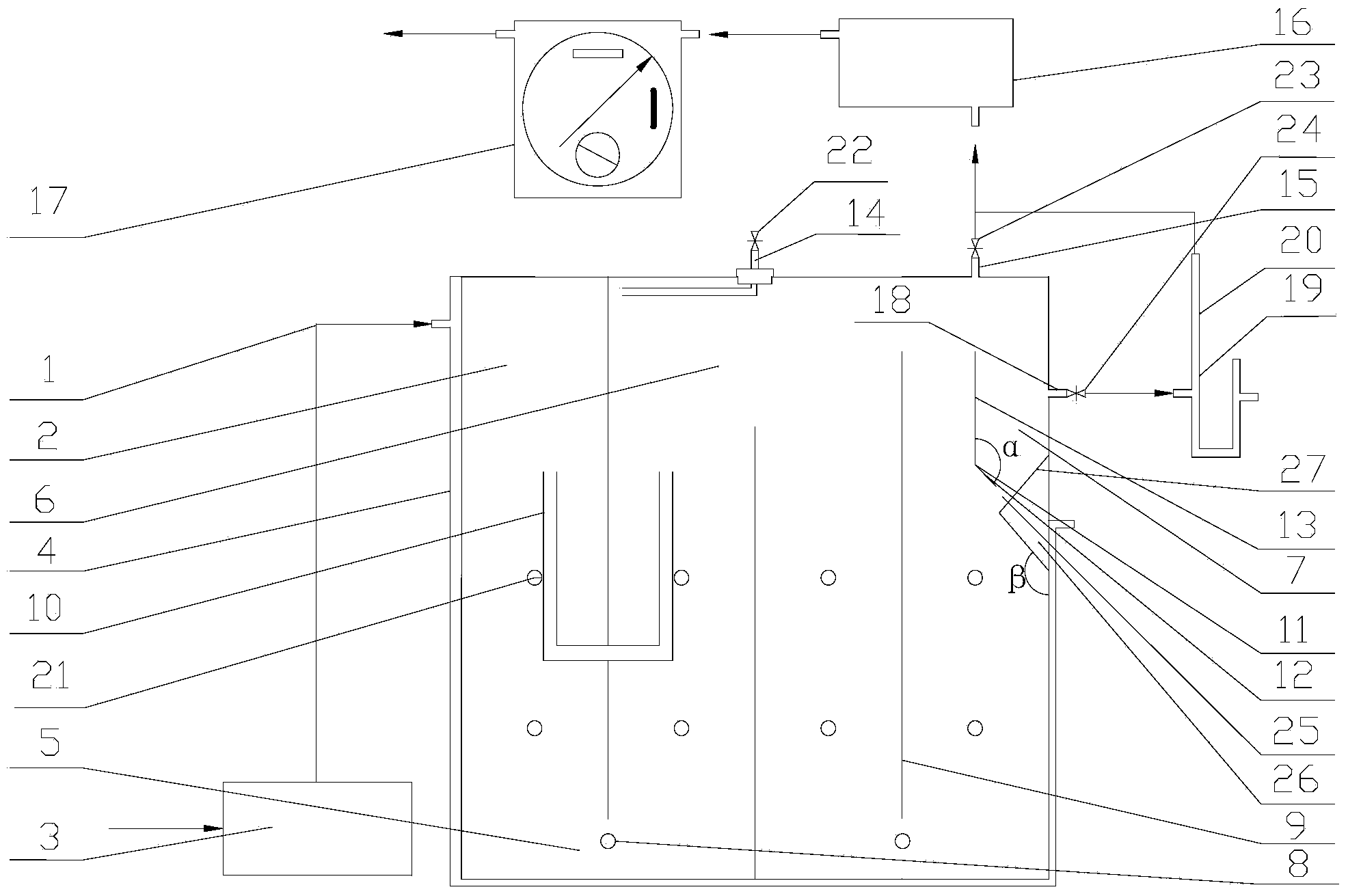

[0024] Reference figure 1 , A self-mixing anammox baffle reactor, comprising a water bath heating system 1 and a reactor body 2, wherein the water bath heating system 1 is arranged on the reactor body 2;

[0025] The water bath heating system 1 includes a heater 3 and a water bath heating layer 4; the water bath heating layer 4 is wrapped on the two side walls and bottom of the reactor body 2, and the heater 3 is connected to the The water bath heating layer 4 is connected;

[0026] The reactor body 2 includes a water distribution zone 5, a reaction zone 6 and a precipitation zone 7; the water distribution zone 5 includes a water inlet 8 arranged at the bottom of the reactor body 2; the reaction zone 6 has a vertical A number of folded plates 9 are provided, and the folded plates 9 divide the reactor body 2 into no less than four cells connected in series, near the upper end of the first folded plate on the left side of the reactor body 2 Connected to the top of the reactor body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com