Carbonizing agent for halogen-free expansion flame-retardant system and preparation method of carbonizing agent

A technology of intumescent flame retardant and char forming agent, which is applied in the direction of organic chemistry to achieve the effects of improving char forming and flame retardancy, improving compatibility, and improving the deterioration of mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

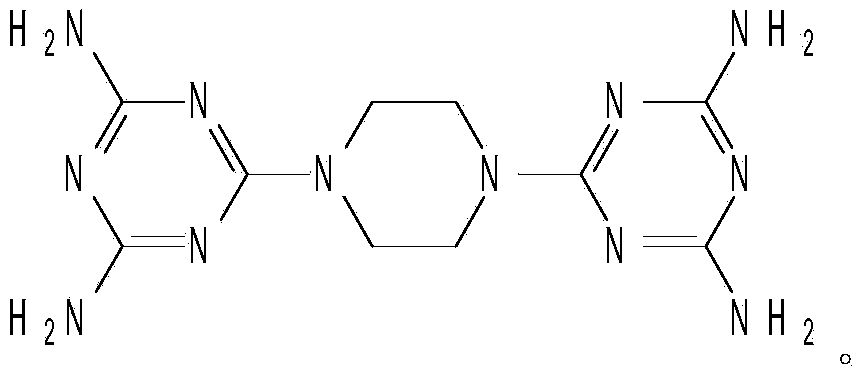

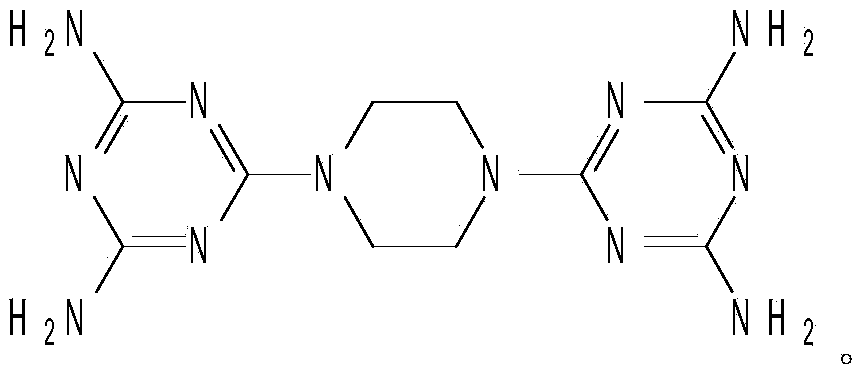

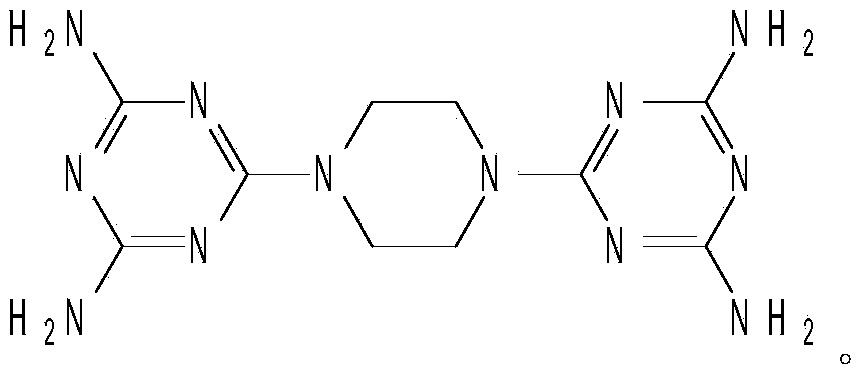

Image

Examples

Embodiment 1

[0026] Add cyanuric chloride and acetone to a four-necked flask equipped with a stirrer, a dropping funnel, a thermometer and a reflux condenser to prepare a solution with a volume molar concentration of 1.25 mol / L, and stir under a nitrogen atmosphere to make trimerization Cyanogen chloride is dispersed evenly, and then piperazine is added dropwise, and the reaction molar ratio of it to cyanuric chloride is 0.3:1. Control the temperature at 0-5°C in an ice bath, and add ammonia water dropwise after reacting for 5 hours. The reaction molar ratio of cyanuric chloride and ammonia in ammonia water is 1:1.7. Heat up to 25°C, continue to stir for 10 hours, add sodium hydroxide, the reaction molar ratio of it to cyanuric chloride is 2.5:1, and raise the temperature to 60°C, continue to react for 6 hours, then filter and dry to obtain the final The product is a char-forming agent for halogen-free intumescent flame retardant systems.

Embodiment 2

[0028] Add cyanuric chloride and 1-methyl-2-pyrrolidone to a four-necked flask equipped with a stirrer, a dropping funnel, a thermometer and a reflux condenser, and prepare a solution with a volume molar concentration of 0.8mol / L, in nitrogen Stir under the protection of the atmosphere to disperse the cyanuric chloride evenly, then add piperazine dropwise, the reaction molar ratio of the piperazine to the cyanuric chloride is 0.7:1, control the temperature in an ice bath to 0°C, react for 6 hours, drop Add ammonia. The reaction molar ratio of cyanuric chloride and ammonia in ammonia water is 1:2.3. Heat up to 30°C, continue to stir for 8 hours, add sodium bicarbonate, the reaction molar ratio of it to cyanuric chloride is 3.5:1, and raise the temperature to 70°C, continue to react for 4 hours, then filter and dry to obtain the final The product is a char-forming agent for halogen-free intumescent flame retardant systems.

Embodiment 3

[0030] Add cyanuric chloride and N,N-dimethylacetamide in the four-necked flask that stirrer is installed, dropping funnel, thermometer and reflux condenser, be mixed with the solution that volume molar concentration is 1.5mol / L, in Stir under the protection of nitrogen atmosphere to disperse cyanuric chloride evenly, then add piperazine dropwise, the molar ratio of its reaction with cyanuric chloride is 0.5:1, control the temperature in an ice bath to 3°C, and react for 6 hours, Add ammonia water dropwise, and the reaction molar ratio of cyanuric chloride to ammonia in ammonia water is 1:2.0. Heat up to 30°C, continue to stir for 8 hours, add triethylamine, the reaction molar ratio of it to cyanuric chloride is 3.0:1, and raise the temperature to 70°C, continue to react for 4 hours, then filter and dry to obtain the final The product is a char-forming agent for halogen-free intumescent flame retardant systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com