Environmental-friendly polypropylene foaming bead and preparation method thereof

A technology of foamed beads and polypropylene, applied in the field of preparation of environmentally friendly polypropylene foamed beads, to achieve strong adsorption, good adsorption effect, and simple preparation method

Inactive Publication Date: 2014-01-22

WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the blending system of bamboo charcoal or activated carbon and polypropylene, there are related patents, but this is still blank in the foaming industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment example

[0033] Example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Login to View More

Abstract

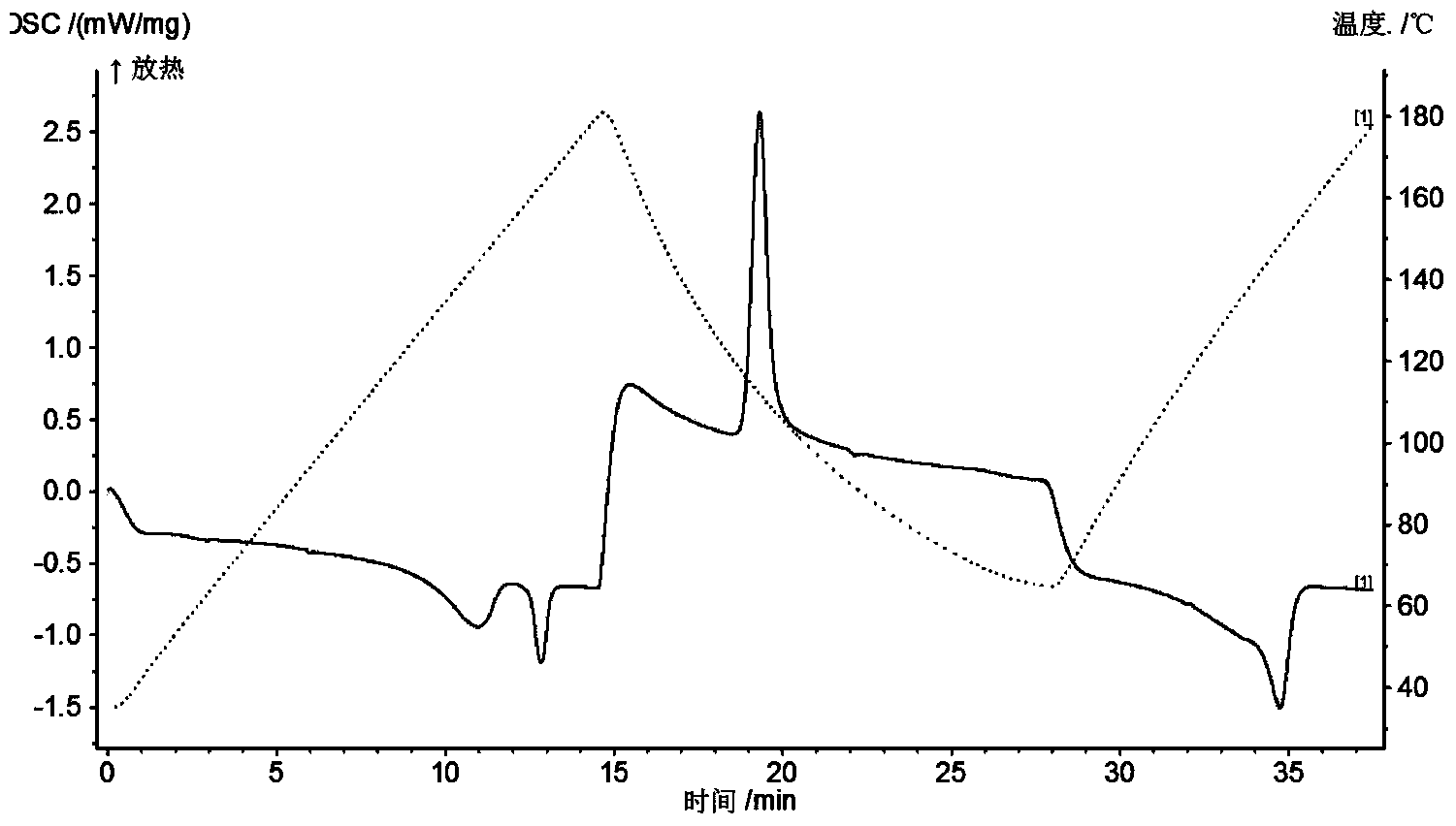

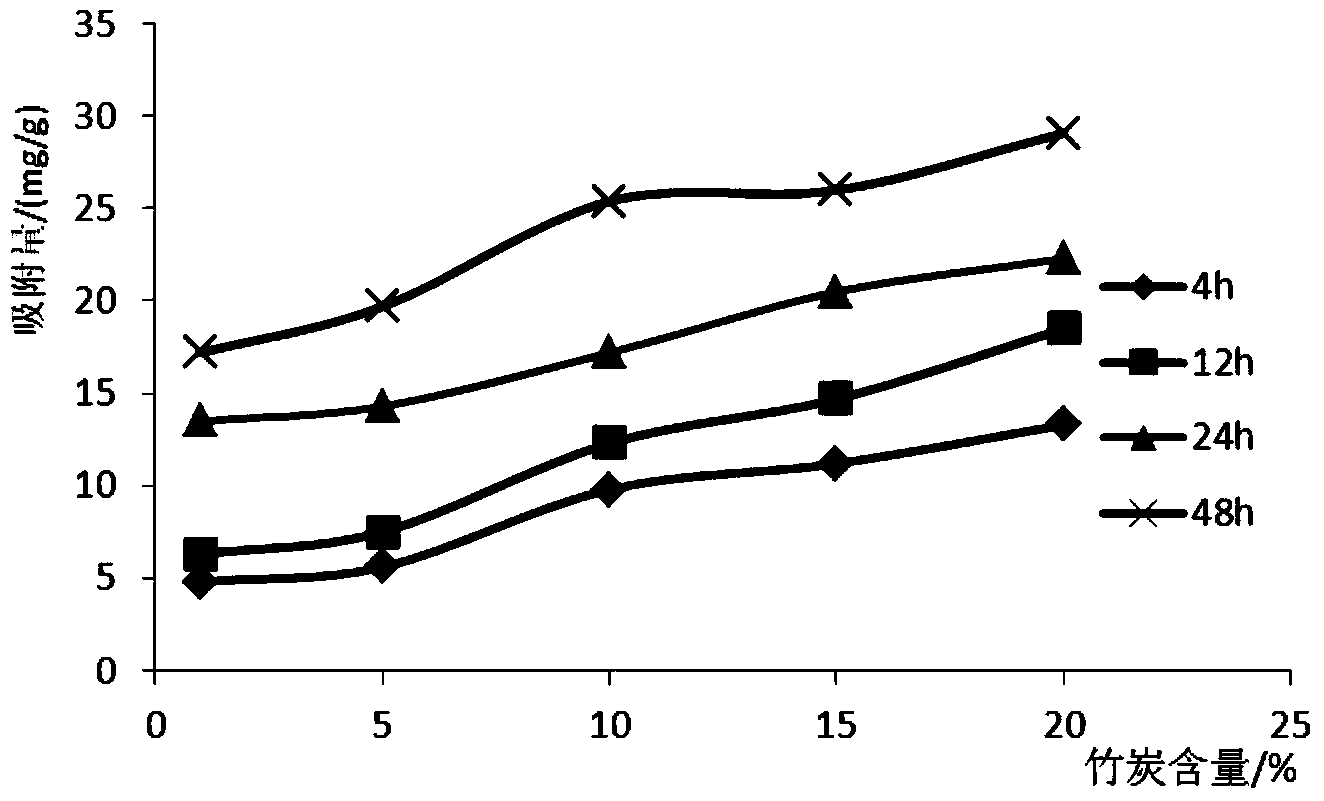

The invention relates to an environmental-friendly polypropylene foaming bead. Preparation of the foaming bead comprises steps of: a) subjecting a polypropylene resin and a porous material with an adsorption function to mixing, extrusion, wire drawing and granulation through an extruder to obtain polypropylene particles; and b) adding the polypropylene particles into a reactor, heating and pressuring, and releasing into the air in an instant to obtain a certain multiplying power of the environmental-friendly polypropylene foaming beads having adsorption, air purification and disinfection functions. The porous material with the adsorption function comprises active silicon, active carbon, active alumina, bamboo charcoal, graphitized carbon black, active carbon fiber, and the like. The porous material with the adsorption function accounts for 0.1%-20% by weight of the total adding amount of the polypropylene. The porous material with the adsorption function has a particle size of 700-1200 meshes, and a pore diameter of 2-500 nm. The polypropylene foaming bead has a great application potential in environment purification of automobile inner decoration, home decoration, and other industries.

Description

technical field [0001] The invention relates to a preparation method of environment-friendly polypropylene foam beads with the functions of adsorption, air purification and bacteria removal, and is applied to the fields of environmental purification and buffering such as automotive interior parts, packaging materials, and home decoration materials. Background technique [0002] Expanded polypropylene materials include various engineering plastics and are used in various fields due to their excellent mechanical strength, heat resistance, machinability, flame resistance, and recyclability. For example, automotive interior parts, packaging materials, building materials, heat insulation materials, etc. Especially in the field of transportation such as automobiles, expanded polypropylene materials have been used in various parts such as bumpers, sun visors, tool boxes, seats, etc. [0003] The smell of new cars, newly renovated houses, newly added furniture and electrical applia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/16C08L23/14C08L23/12C08K3/02C08K3/04C08K3/22C08K7/06C08K3/08C08J9/12

CPCC08L23/12C08J9/0061C08J9/16C08J2323/12C08J2323/14C08J2423/12C08J2423/14C08K2201/003C08L23/14C08K7/24C08K3/04

Inventor 曾佳黄芸万惠忠朱民

Owner WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com