Guide oil injection device of steel wire rope of haulage winch

An oil injection device and wire rope technology, which is applied in hoisting devices, engine components, engine lubrication, etc., can solve problems such as fast wear of wire ropes, contamination of lubricating oil, and corrosion of wire ropes, so as to prevent rust and winding deviation, and ensure safe transportation The effect of improving and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

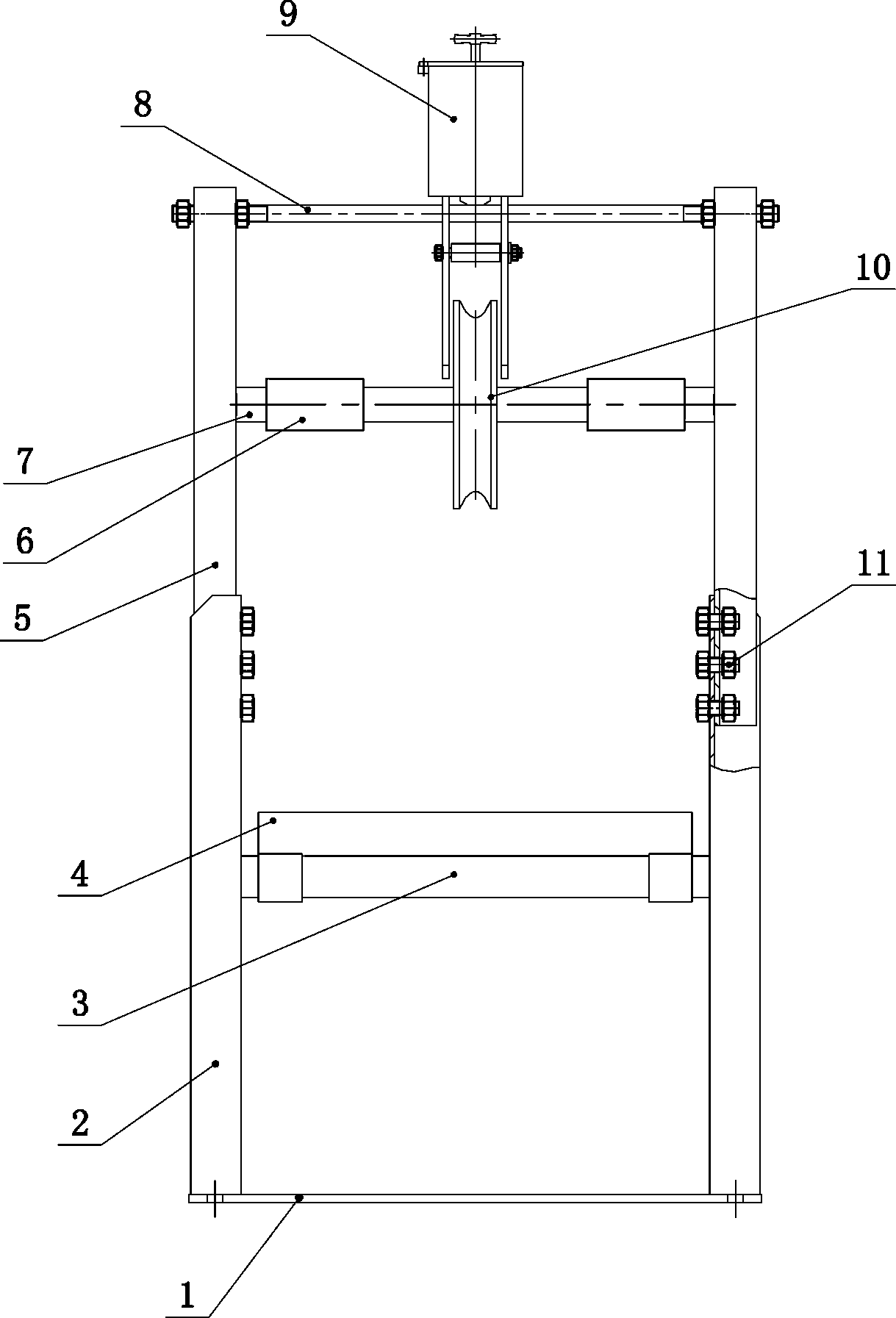

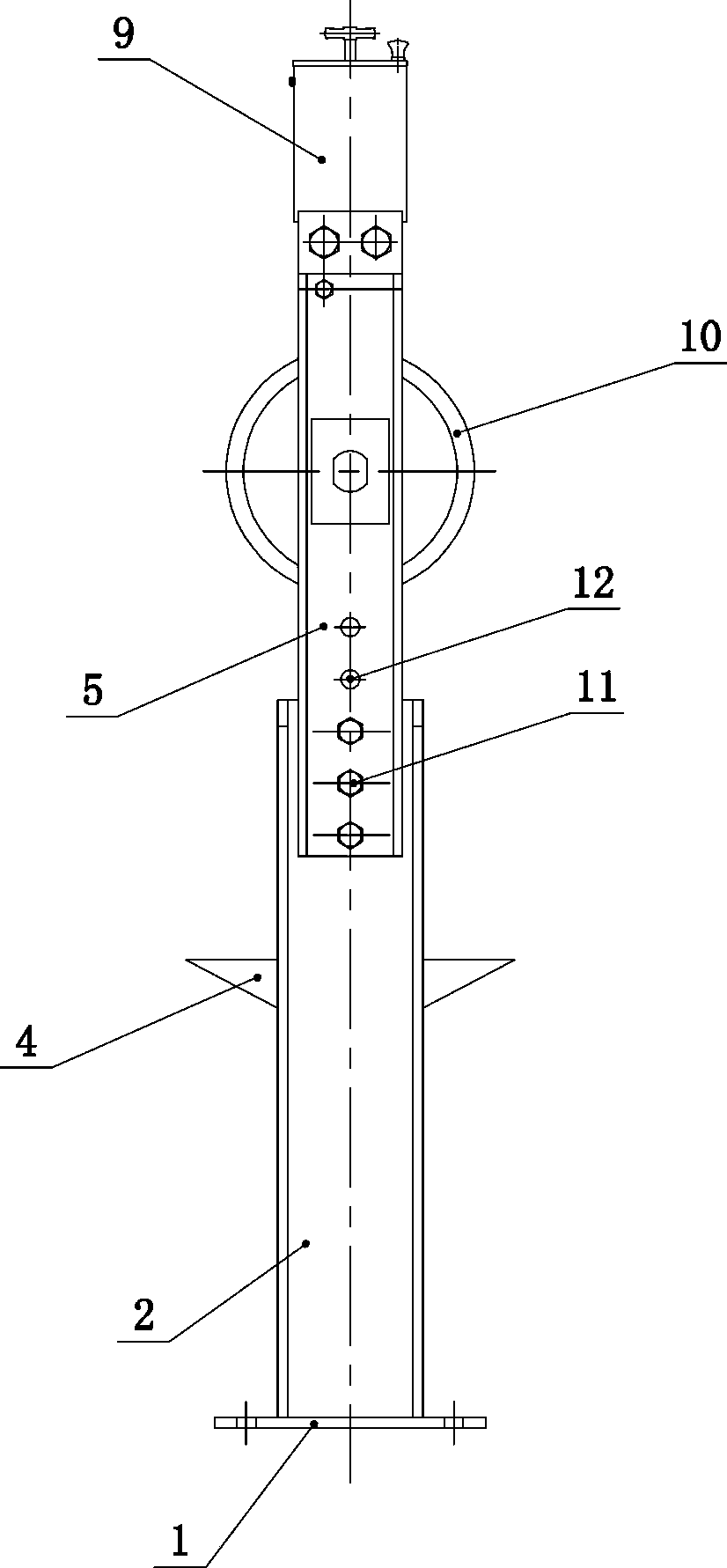

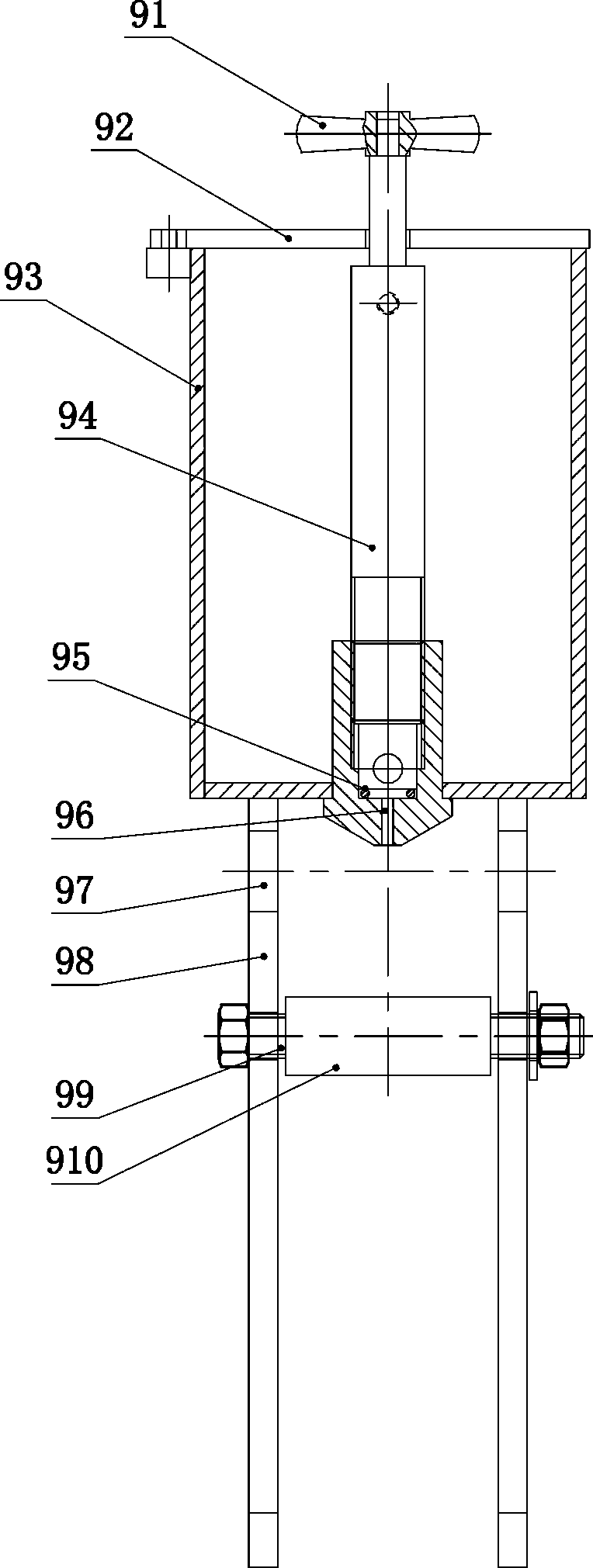

[0025] A transport winch wire rope guide oiling device, such as Figure 1 to Figure 4 As shown, it includes the underframe. The underframe includes upright columns 2 correspondingly arranged on the left and right. The upright column 2 is telescopically connected with telescopic station beams 5. The telescopic station beams 5 are connected with wheel shafts 7 and guide sliders 8. The guide sliders 8 are located on the wheel axles. 7 above, on the wheel shaft 7, slide left and right to be connected with guide swimming sheave 10, on guide slide bar 8, slide left and right and be connected with oiler 9; Oiler 9 comprises oil storage tank 93, and oil storage tank 93 has the opening upward, storage An upper cover is connected to the opening of the oil tank 93, and an oil filling valve is connected to the upper cover for relative rotation. The oil filling v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com