Light guide device, light source assembly and projection device

A technology of light guide device and light source assembly, applied in the direction of light guide, projection device, optical element, etc., can solve the problems of reducing output light brightness, reducing output light brightness, large light energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

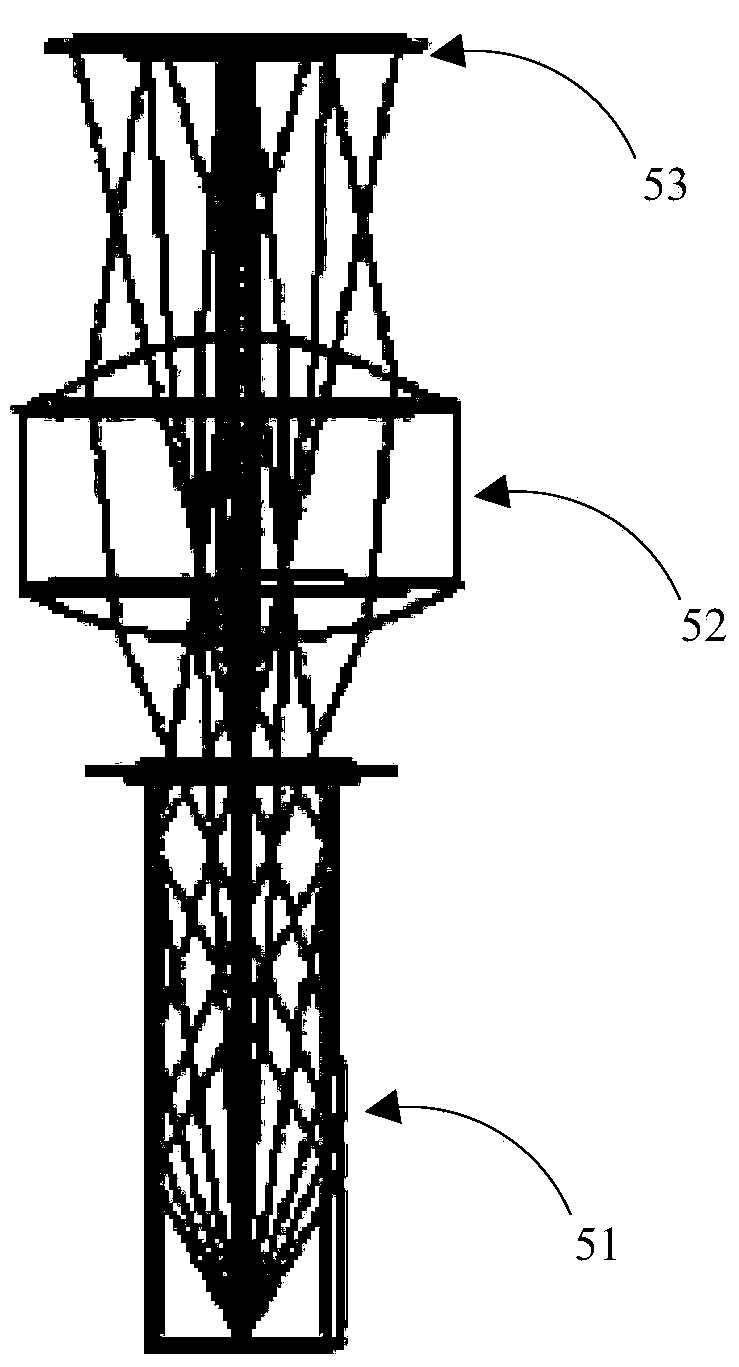

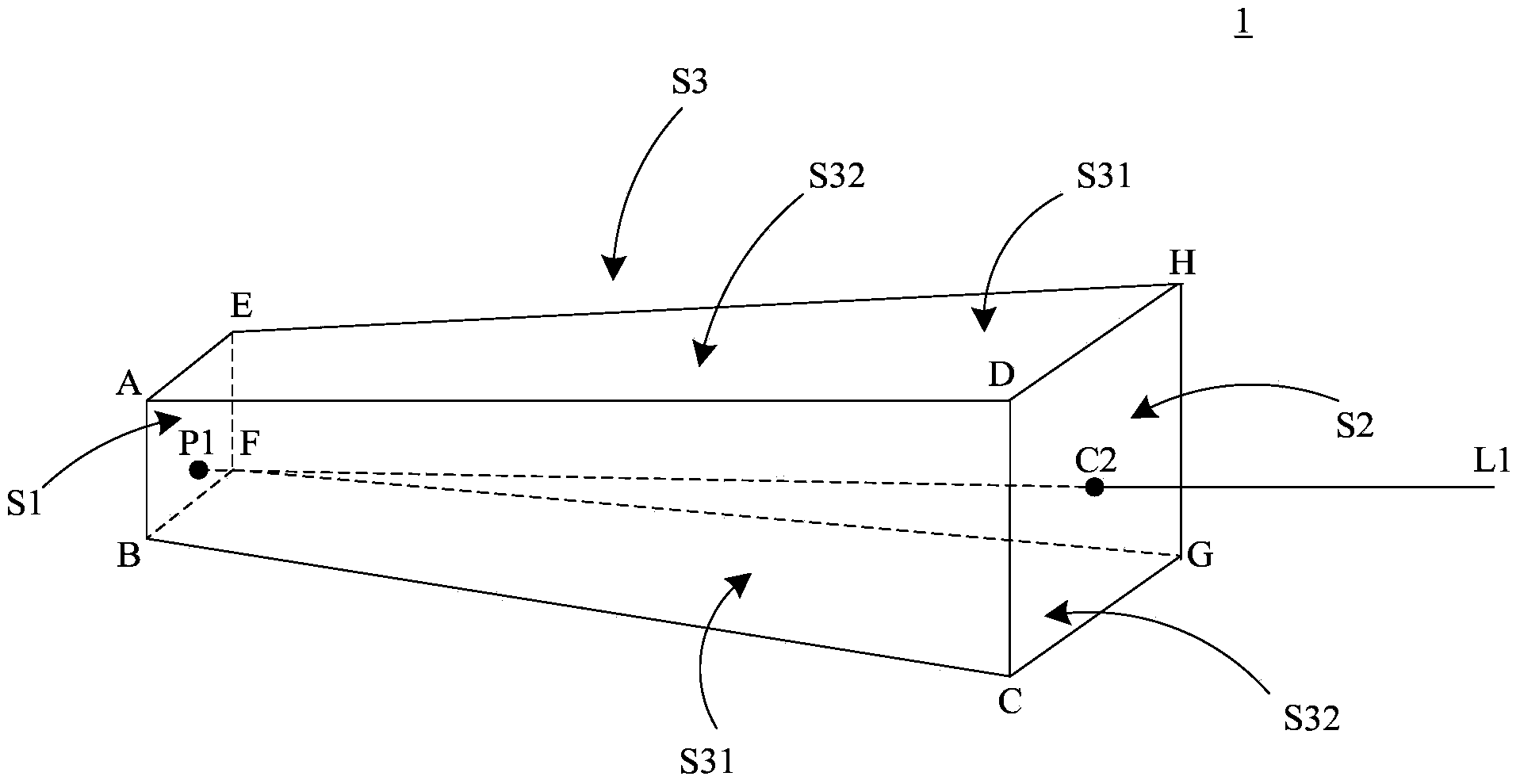

[0028] image 3 A schematic structural view of a light guide device provided by an embodiment of the present invention is shown, as shown in image 3 As shown, the light guide device in the embodiment extends along a straight line. The light guide device 1 has a light incident surface S1 (defined by the vertex ABFE) and a light exit surface S2 (defined by the vertex DCGH), and the light exit surface S2 is located opposite to the light incident surface S1 . In the center C2 of the light-emitting surface S2, a first central axis L1 perpendicular to the light-emitting surface S2 is defined. The intersection point of the first central axis L1 and the light-incident surface S1 is P1, which is not at the center of the light-incidence surface S1, that is, the first A central axis L1 does not pass through the center of the light incident surface S1.

[0029] In addition, the side wall S3 of the light guide device 1 connects the light incident surface S1 and the light exit surface S2...

Embodiment 2

[0038] Figure 5 It shows a schematic structural diagram of another light guide device provided by the embodiment of the present invention, such as Figure 5As shown, the light guide device 1' in this embodiment extends along a straight line, and the light guide device 1' has a light incident surface S1' and a surface S2'. The photoconductive device in this embodiment and image 3 The difference of the light guide device shown in is that: in this embodiment, the light incident surface S1' and the light exit surface S2' of the light guide device 1' are both circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com