Color film substrate and preparation method thereof, display panel and preparation method thereof and display device

一种彩膜基板、显示面板的技术,应用在光机械设备、图纹面的照相制版工艺、光学等方向,能够解决隔垫物压缩量小、重力Mura、产能降低等问题,达到提升可靠性、降低风险、增加压缩量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

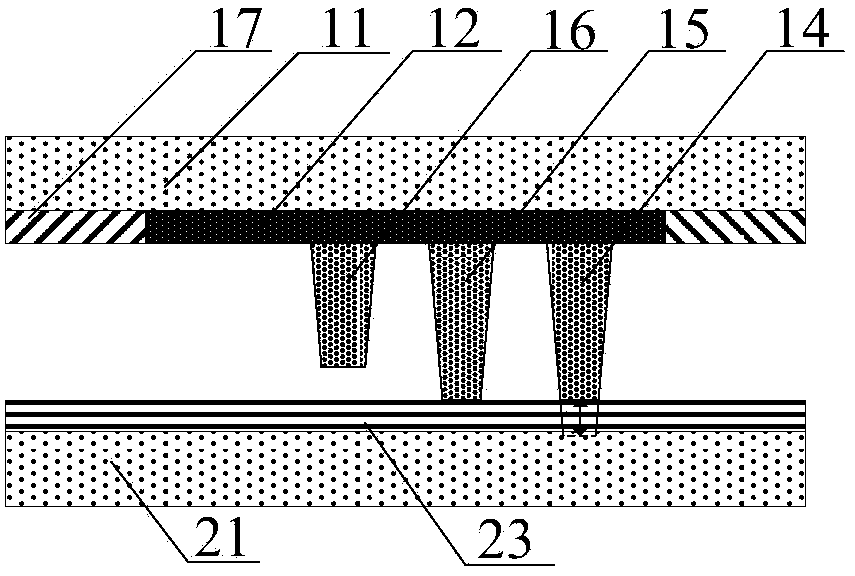

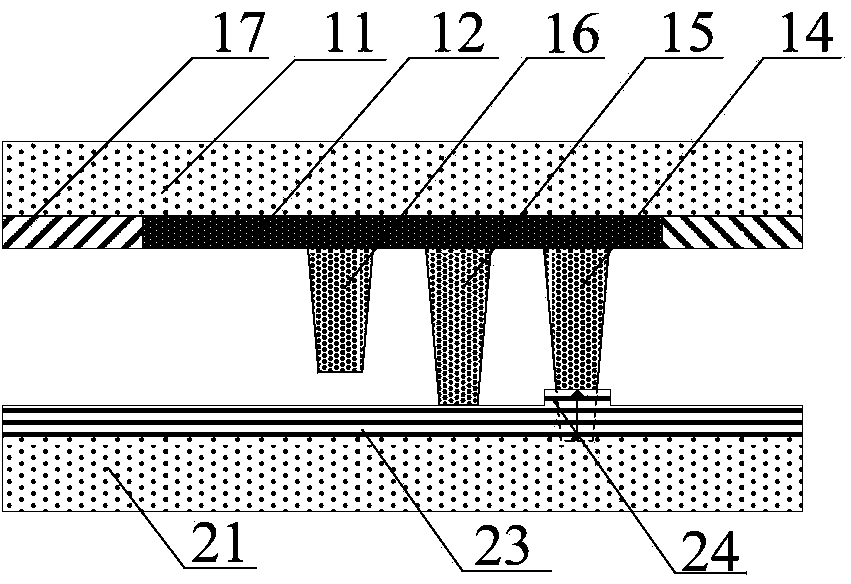

[0068] In this embodiment, a color filter substrate is firstly provided, such as figure 1 As shown in , the color filter substrate mainly includes a first base substrate 11, a black matrix 12 and a color resist layer 17 disposed on the first base substrate 11, and spacers disposed on the black matrix 12; The spacers in this embodiment include a main spacer 14, a first auxiliary spacer 15 and a second auxiliary spacer 16, the main spacer 14 is arranged on the pillow layer 13, and the first auxiliary spacer 15 and the second auxiliary spacer 16 are directly arranged on the black matrix 12; wherein, the main spacer 14 is mainly used to prevent gravity Mura, the first auxiliary spacer 15 is mainly used to prevent Push (wiping) Mura, and the second Auxiliary spacer 16 is mainly used to prevent blackening Mura; Certainly, first auxiliary spacer 15 and second auxiliary spacer 16 may not be provided, or only first auxiliary spacer 15 and second auxiliary spacer may be provided. One o...

Embodiment 2

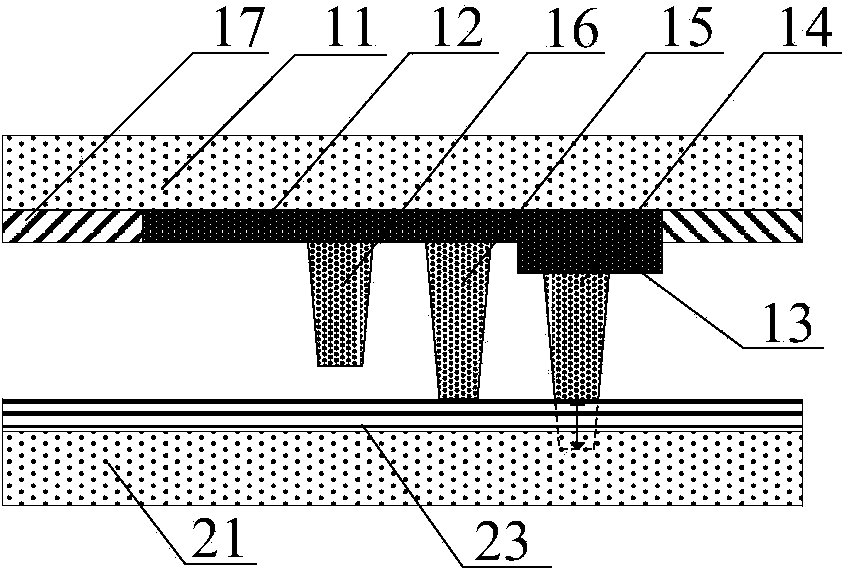

[0114] In this embodiment, a color filter substrate is firstly provided; Figure 7 As shown in , the color filter substrate mainly includes a first base substrate 11, a black matrix 12 and a color resist layer 17 disposed on the first base substrate 11, and spacers disposed on the black matrix 12; The spacers in this embodiment include a main spacer 14, a first auxiliary spacer 15 and a second auxiliary spacer 16; the main difference from Embodiment 1 is that in this embodiment, the pillow layer 13 is Multi-level stepped structure; for example, it can be a three-level stepped structure, the main spacer 14 is arranged on the highest step, the first auxiliary spacer 15 is arranged on the next highest step, and the second auxiliary spacer 16 is arranged on the lowest step; or, it can be a two-stage stepped structure, the main spacer 14 is arranged on the highest step, the first auxiliary spacer 15 is arranged on the lowest step, and the second auxiliary spacer The objects 16 are...

Embodiment 3

[0134] This embodiment provides a display device including the display panel provided in Embodiment 1 or Embodiment 2. Because in this display device, the compression amount of the spacer is increased by the pillow layer arranged on the black matrix, the risk of gravity Mura is reduced, and the picture display quality and the reliability of the display device are improved; in addition, because the pillow The thickness of the layer can be flexibly set according to requirements, so the compression amount of the spacer can be flexibly controlled without being limited by various limitations of the prior art, thereby improving the manufacturing efficiency of the display device and reducing the production cost. The above-mentioned display device may be any product or component with a display function such as a liquid crystal display panel, electronic paper, liquid crystal TV, liquid crystal display, digital photo frame, mobile phone, and tablet computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com