An air gap armature motor

An armature and air gap technology, which is applied in the fields of high-capacity high-temperature superconducting motors for ship propulsion, high-temperature superconducting wind generators, and air-gap armature motors, can solve the problems of limited heat dissipation capacity and long thermal path, and achieve increased The effect of reducing the number of conductors, reducing circulation and eddy current losses, and reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

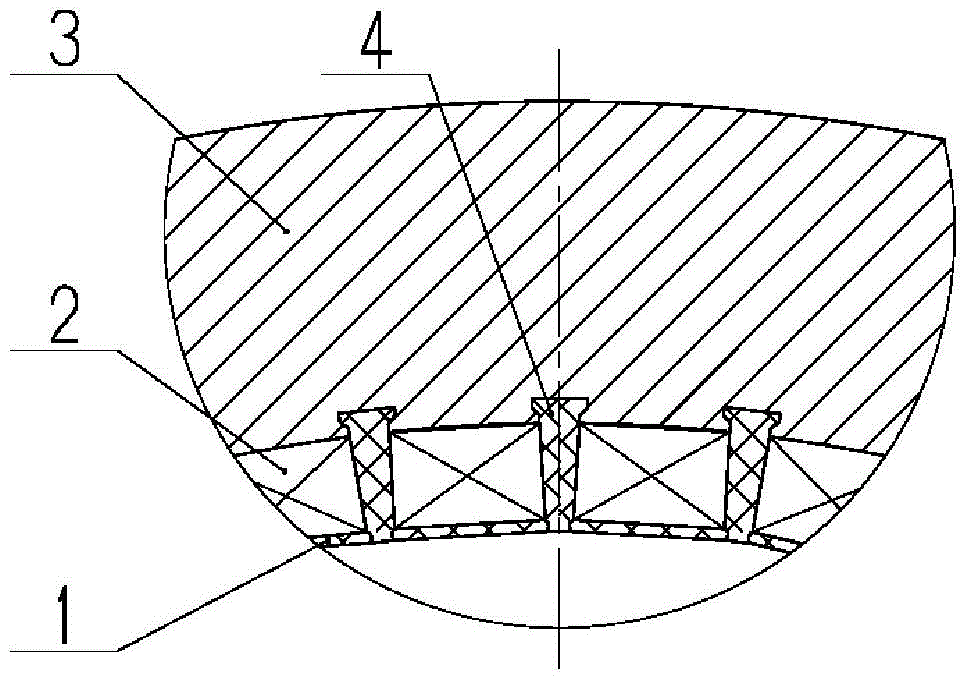

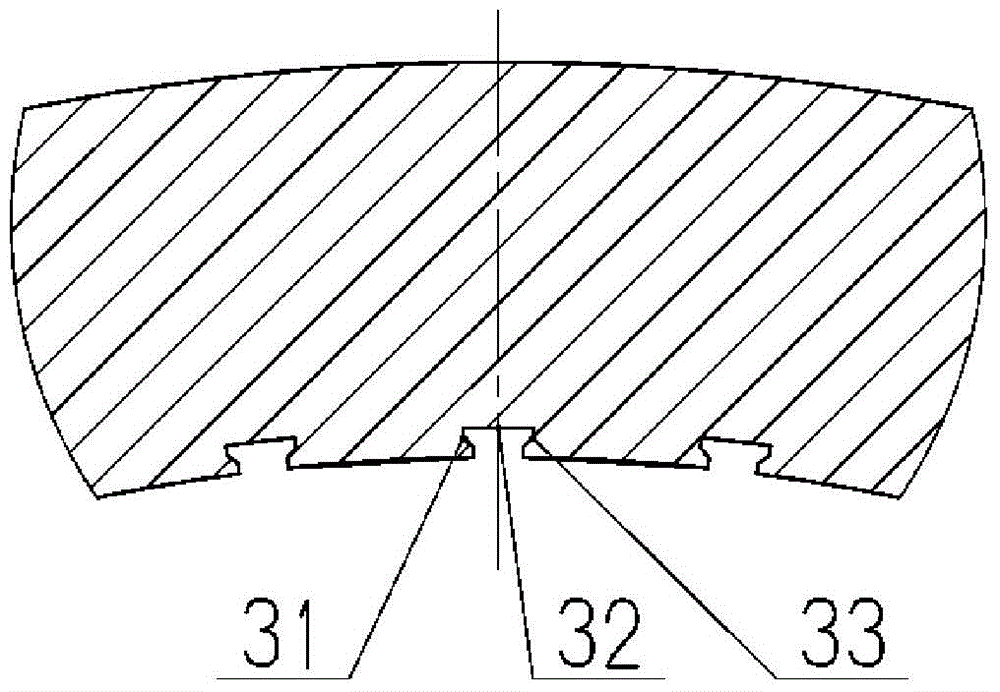

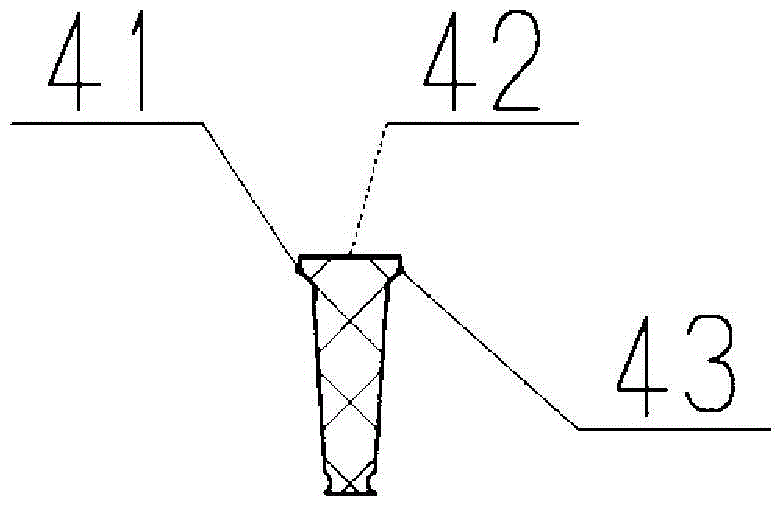

[0027] Example 1: Such as Figure 1-7 Shown is a basic embodiment of the invention. An air-gap armature motor, including a stator, a rotor and a bearing system, the stator is composed of a machine base and an air-gap armature, and the air-gap armature is composed of an iron core punch 3, a coil support 4, a coil 2 and a slot 1; the core punch 3 is an annular structure with a dovetail groove in the axial direction; the coil support 4 is an isosceles trapezoidal wedge-shaped strip embedded in the dovetail groove; the coil 2 is a belt The multi-turn shuttle structure with cooling channels and transposition is co-located and supported by the iron core punch 3 and the coil support 4 .

Embodiment 2

[0028] Example 2: is a further example. The difference from Embodiment 1 is that the coil 2 of the air gap armature motor includes a coil lead wire 21 and a coil cooling pipe joint 22 . The cooling method of the coil 2 is liquid internal cooling, and the cooling medium is deionized water or transformer oil. Coil 2 is a double-layer, transposed multi-turn formed coil. It is another embodiment when the coil 2 is a single layer. The coil 2 is a hollow copper conductor with a small wire gauge. The cross section of the hollow copper conductor is a square on the outside and a circle on the inside. It can be selected as a square on the outside, or a circle on the outside, or a square on the outside is another embodiment. The material of the coil support 4 is a composite material that is non-magnetic, non-conductive, high-strength and excellent in thermal conductivity, and may also be plastic.

Embodiment 3

[0029] Example 3: is yet another further embodiment. The difference from Embodiment 2 is that the coil 2 is a combination of a small-gauge hollow copper wire and a small-gauge solid copper wire. An outer circle and an inner circle, or an outer circle and an inner square are other embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com