Sensorless vector control system and method for permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and vector control, which is applied in the direction of vector control system, control system, motor generator control, etc., and can solve problems affecting the reliability of vector control system, switching failure, and small induced electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

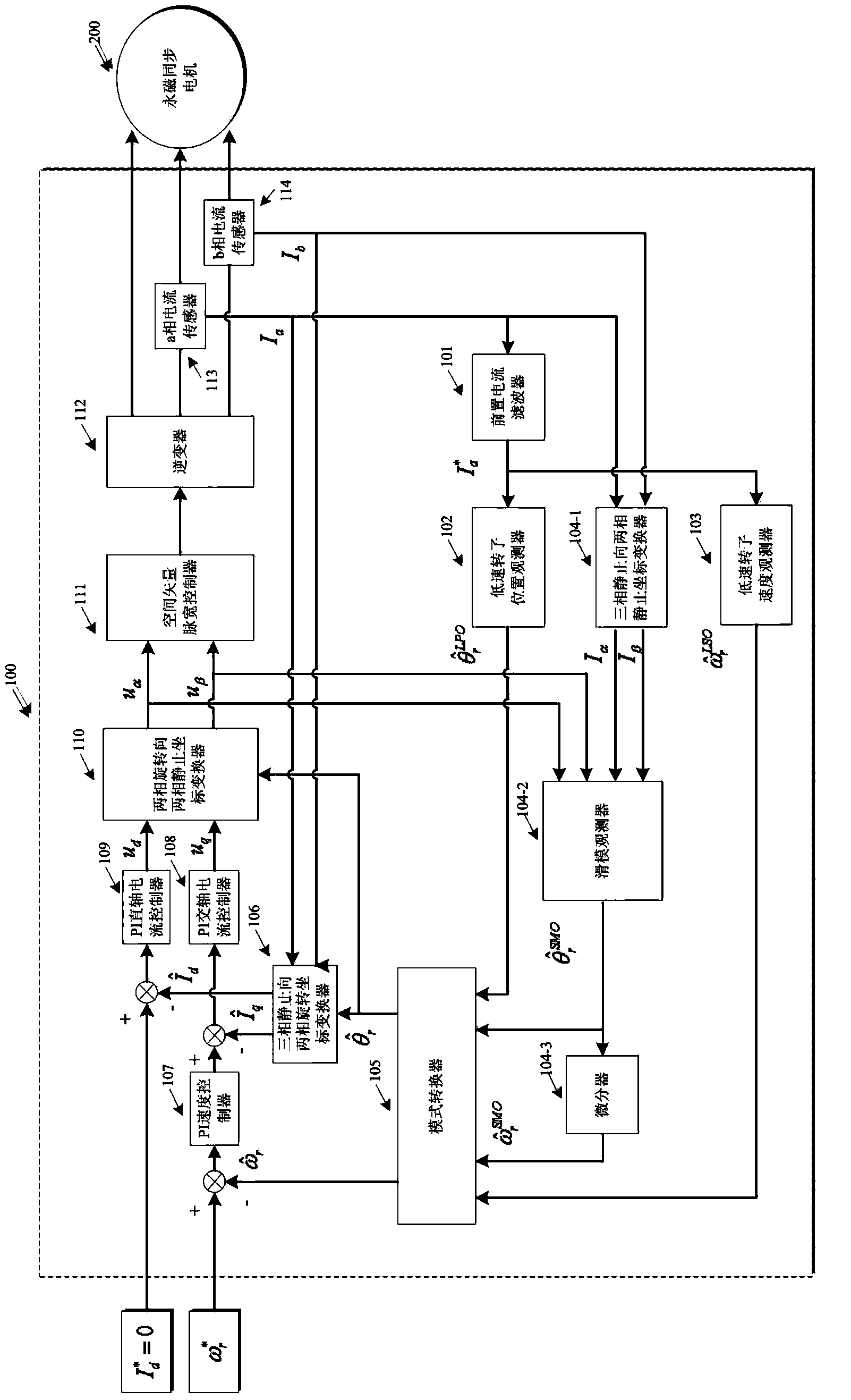

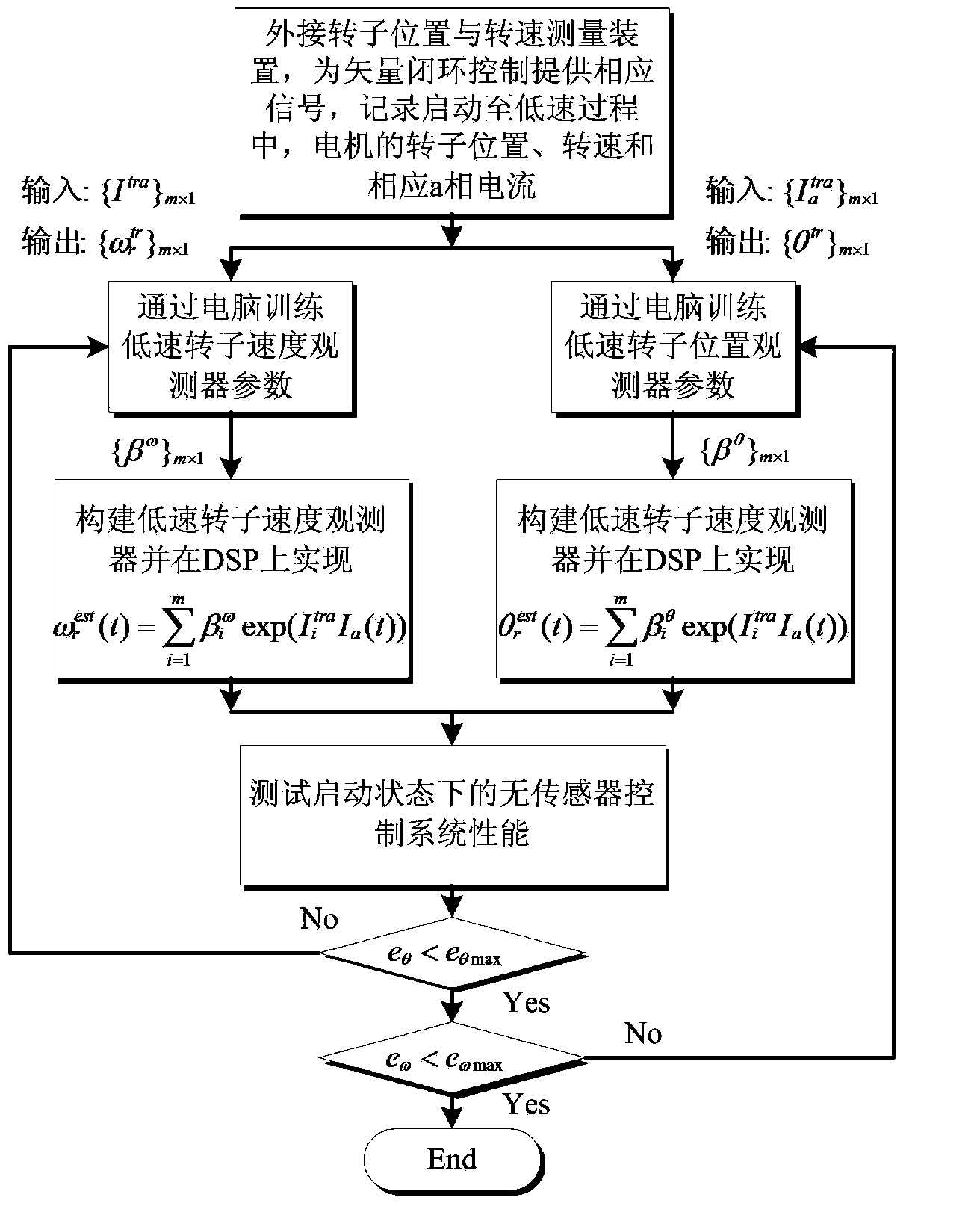

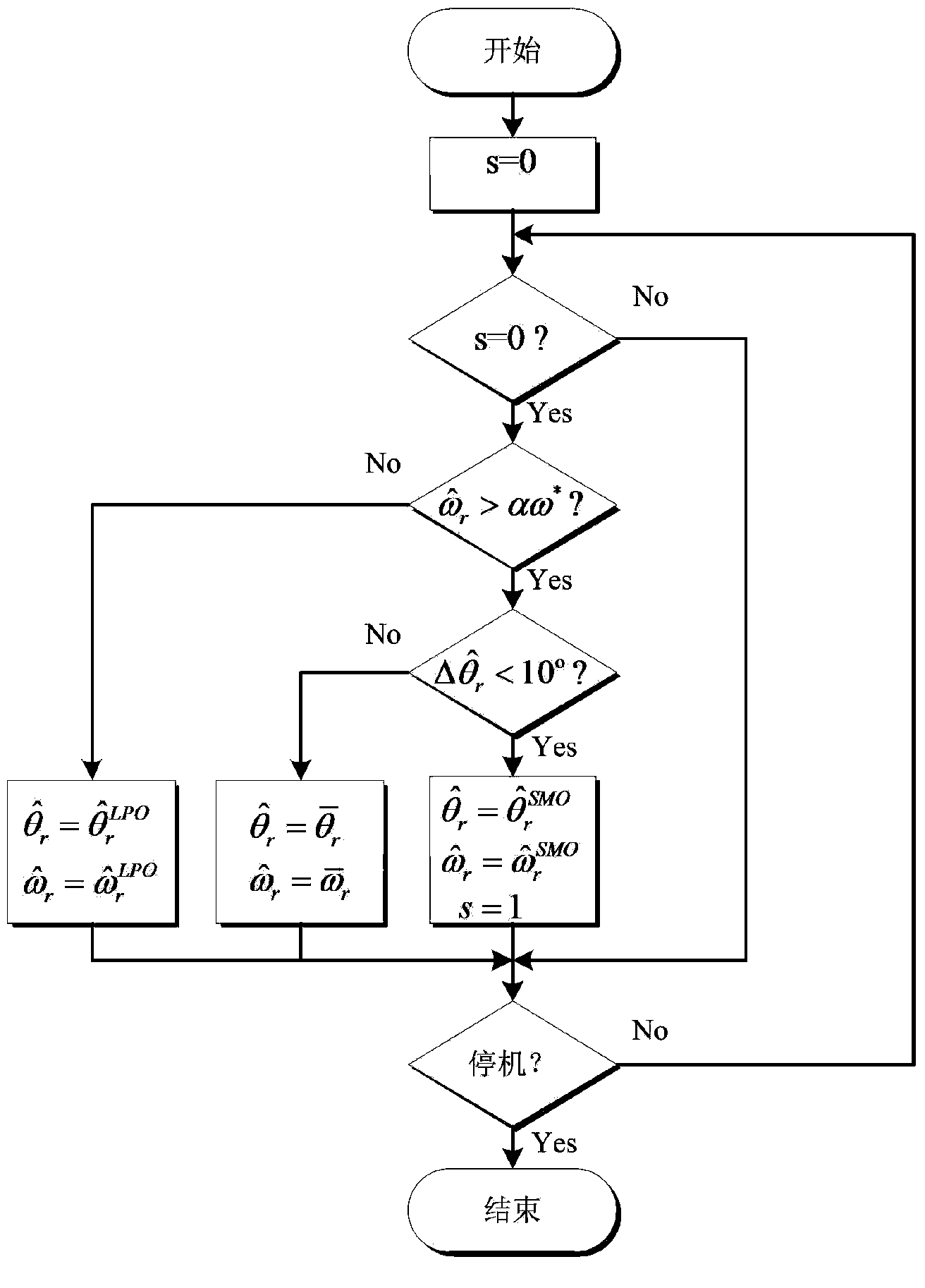

[0054] Such as figure 1 combine figure 2 , image 3 As shown, according to a preferred embodiment of the present invention, a sensorless vector control method of a permanent magnet synchronous motor, the method realizes the sensorless vector control of the permanent magnet synchronous motor in the range of starting, low speed, medium speed to full speed.

[0055] refer to figure 1 As mentioned above, the sensorless vector control system of permanent magnet synchronous motor includes: pre-current filter (101), low-speed rotor position observer (102), low-speed rotor speed observer (103), three-phase stationary to two-phase stationary coordinates Converter (104-1), sliding mode observer (104-2), differentiator (104-3), mode converter (105), three-phase stationary to two-phase rotating coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com