Atmospheric pressure magnetic field enhanced low temperature plasma brush generator

A low-temperature plasma and generating device technology, applied in the direction of plasma, electrical components, etc., can solve the problems of wasteful energy consumption, increased operating costs, and unsatisfactory devices, and achieve low discharge power, extended service life, and rich active species Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Those skilled in the art consider reducing the energy consumption and operating cost of the plasma generator, usually by adjusting the external DC voltage to reduce the discharge current or adjusting the flow controller to reduce the working gas flow. However, the reduction of the discharge current or the gas flow will reduce the volume of the plasma jet, reduce the working efficiency of the plasma generator, and even fail to generate a stable plasma jet, making it unable to work normally.

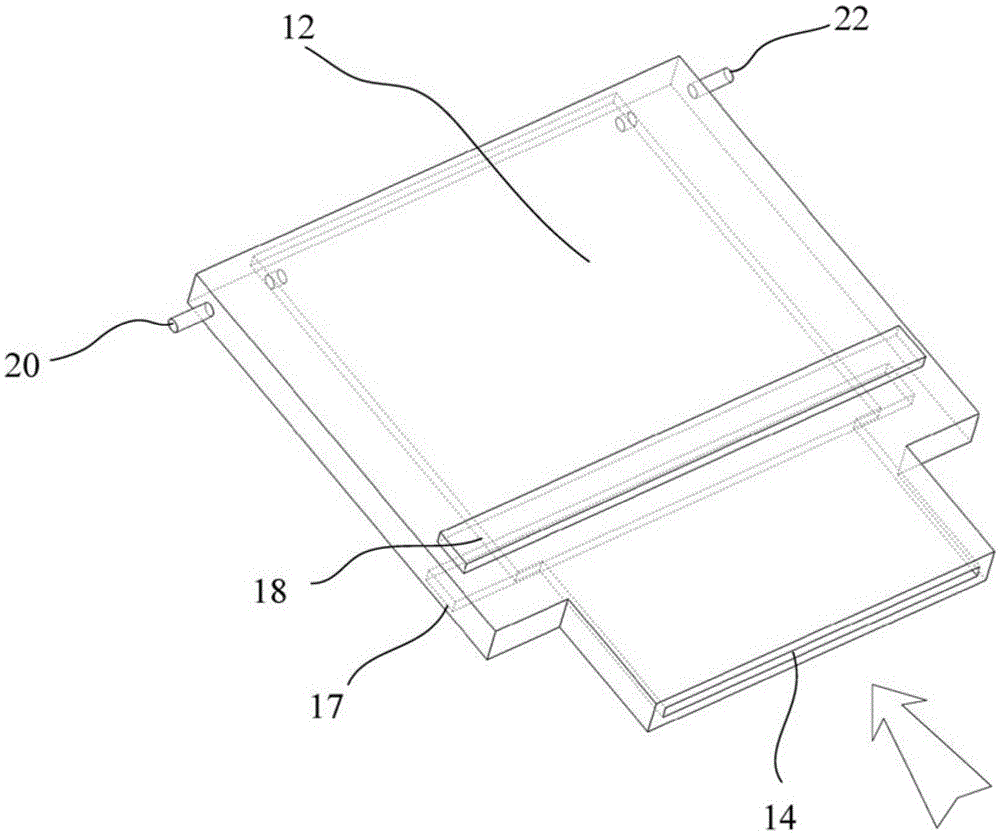

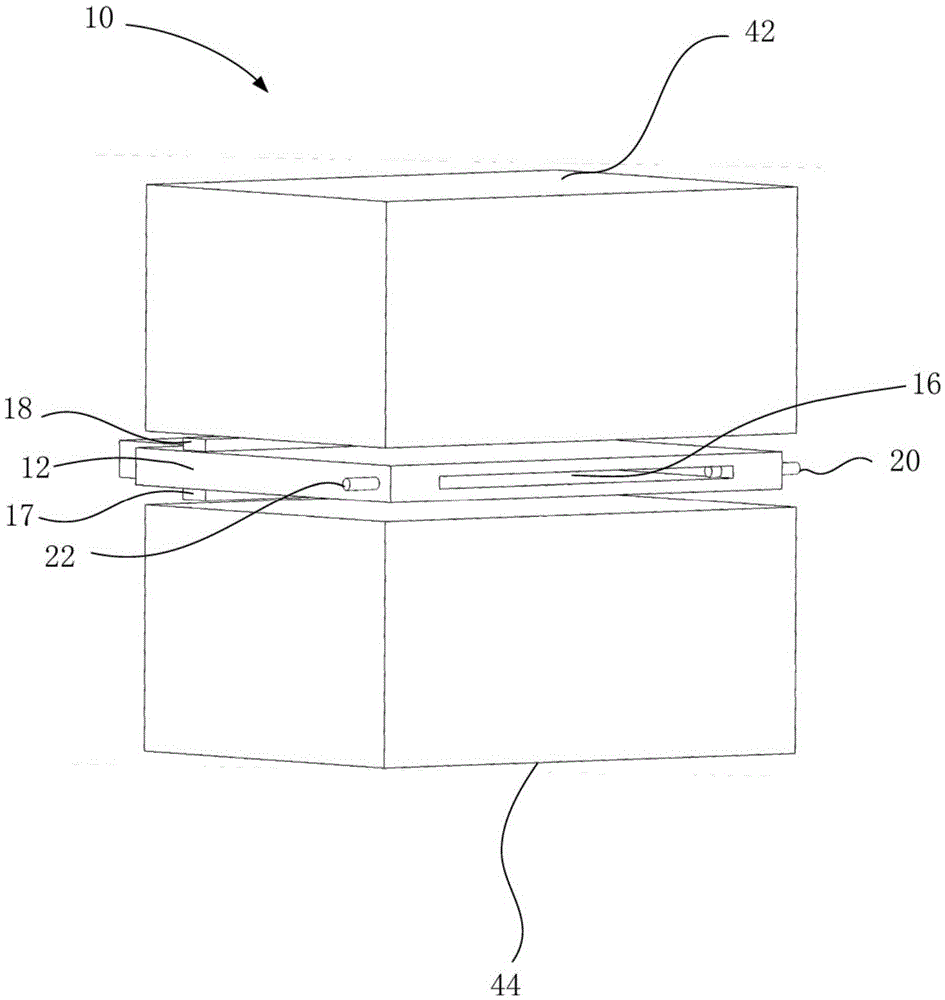

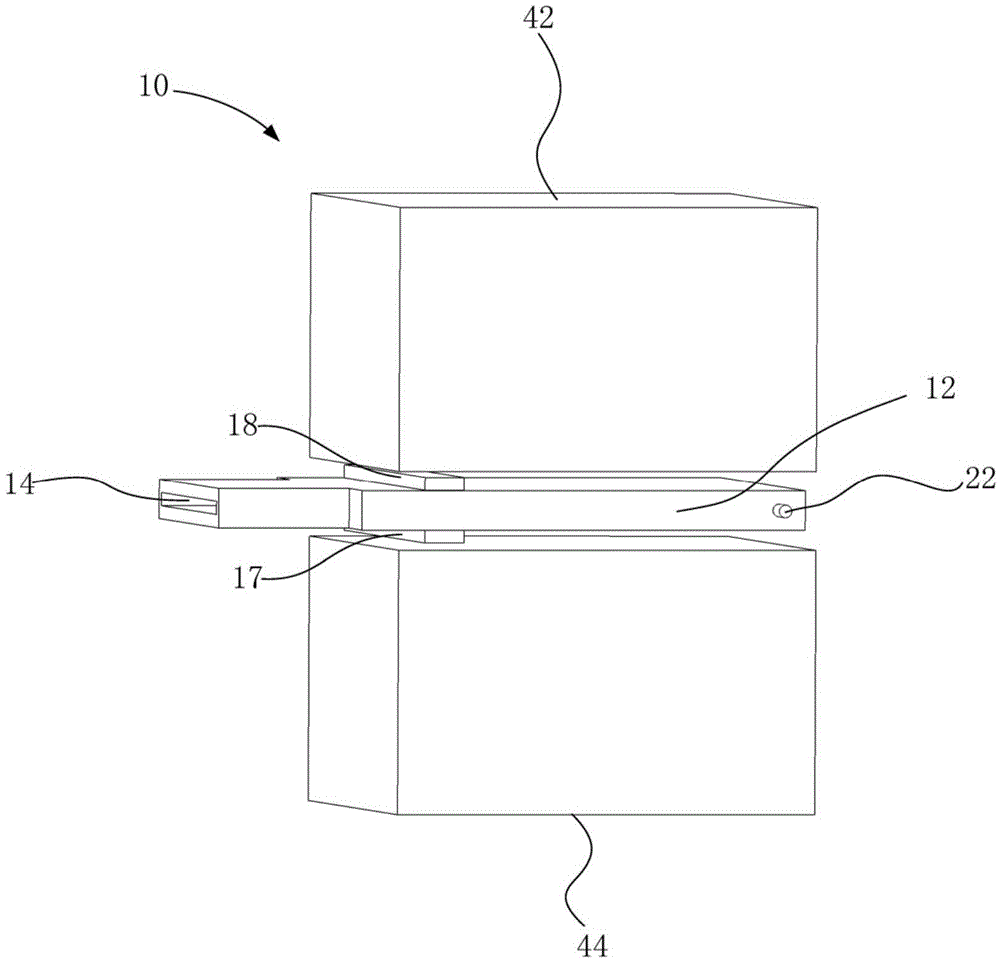

[0029] After a lot of theoretical analysis and experimental research, the present invention skillfully utilizes the principle of electromagnetic induction and achieves remarkable effects. The specific working principle is: the working gas (plasma maintenance gas and / or active gas) is first pre-ionized by dielectric barrier discharge. Part of the pre-ionized working gas flows through the main discharge area for discharge, so that there are a large number of charges (electrons and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com