Simple battery pack battery equalization method

An equalization method and battery equalization technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of poor equalization effect and complex equalization method, and achieve the effects of short equalization time, improved cycle life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

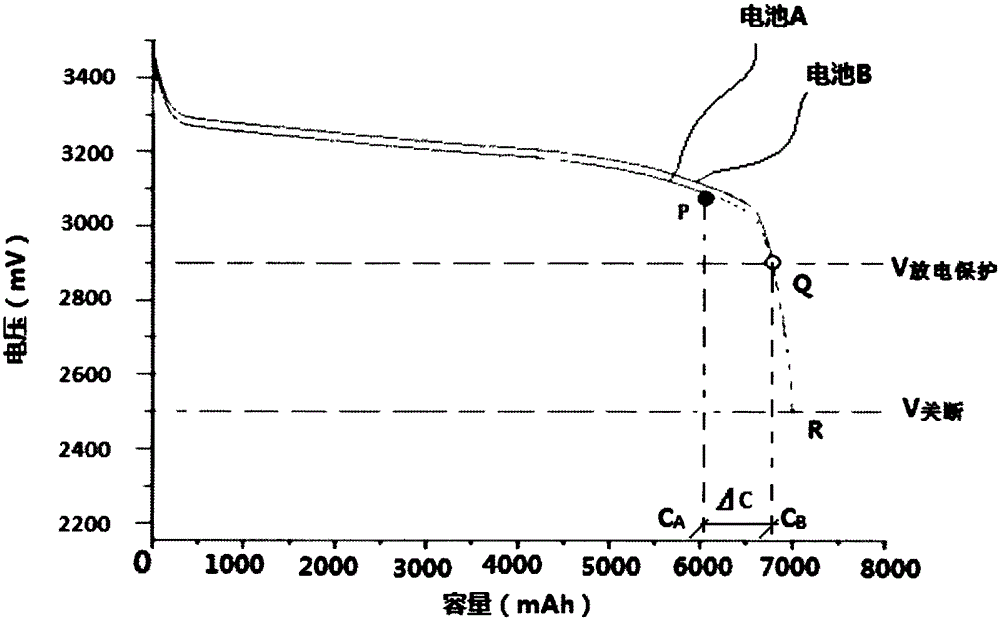

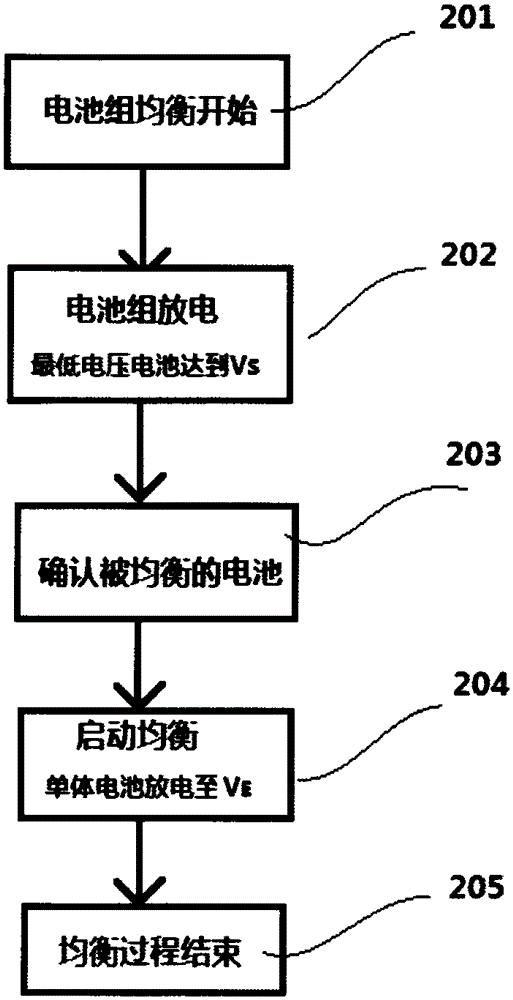

Method used

Image

Examples

Embodiment 1

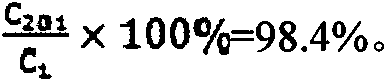

[0025]Sixteen 3.2V105Ah lithium iron phosphate batteries are connected in series to form a battery pack, and it is equipped with a management system board and a battery voltage acquisition board with a balance module. The maximum charging voltage allowed for a single cell in a battery pack is 3.65V, and the minimum discharge voltage is 2.50V; the voltage of a single cell during cycling is limited to a charging voltage of 3.60V and a discharging voltage of 2.85V. Balance setting: V S 2.85V, V E is 2.5V, the equalizing current I J The minimum value is 3A (0.03CA), and the power consumption resistance R is 0.12Ω. According to the first batch of even-numbered batteries and the other batch of odd-numbered batteries, each battery is discharged and balanced. The battery pack is charged and discharged cycle test in the range of 45.6-57.6V with a current of 100A. The test results: the first discharge of the battery pack is 100Ah; the discharge capacity of the battery pack at the 200t...

Embodiment 2

[0027] Connect 32 3.2V105Ah lithium iron phosphate batteries in series to form a battery pack. First, 16 batteries form a module, and then 2 modules are connected in series to form a battery pack. The battery pack is equipped with a management system board and each module has a battery voltage acquisition board with a balancing module. The maximum charging voltage allowed for a single cell in a battery pack is 3.65V, and the minimum discharge voltage is 2.50V; the voltage of a single cell during cycling is limited to a charging voltage of 3.60V and a discharging voltage of 2.85V. Balance setting: V S 2.85V, V E is 2.6V, the balance current I J The minimum value is 2A (0.02CA), and the power consumption resistance R is 0.12Ω. According to the first batch of batteries with an even serial number, and the other batch with an odd serial number, each battery is discharged and balanced. The battery pack is charged and discharged cycle test in the range of 91.2-115.2V with a curre...

Embodiment 3

[0029] Connect 32 pieces of 3.6V33Ah lithium-nickel-manganese-cobalt oxide lithium-ion batteries in series to form a battery pack. First, 16 batteries form a module, and then 2 modules are connected in series to form a battery pack. The battery pack is equipped with a management system board and a battery voltage acquisition board with a balance module for each module. The maximum charging voltage allowed for a single cell in a battery pack is 4.20V, and the minimum discharge voltage is 2.85V; the voltage of a single cell during cycling is limited to a charging voltage of 4.10V, and a discharging voltage of 3.00V. Balance setting: V S 3.00V, V E is 2.85V, the equalizing current I J The minimum value is 2A (0.07CA), and the power consumption resistance R is 0.075Ω. According to the first batch of batteries with an even serial number, and the other batch with an odd serial number, each battery is discharged and balanced. The battery pack is charged and discharged cycle test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com