Horseshoe automatic continuous cleaning machine

A washing machine and horseshoe technology, applied in the field of machinery, can solve the problems of low work efficiency, easy fatigue of staff, etc., and achieve the effects of convenient water leakage, reduced resistance, and continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

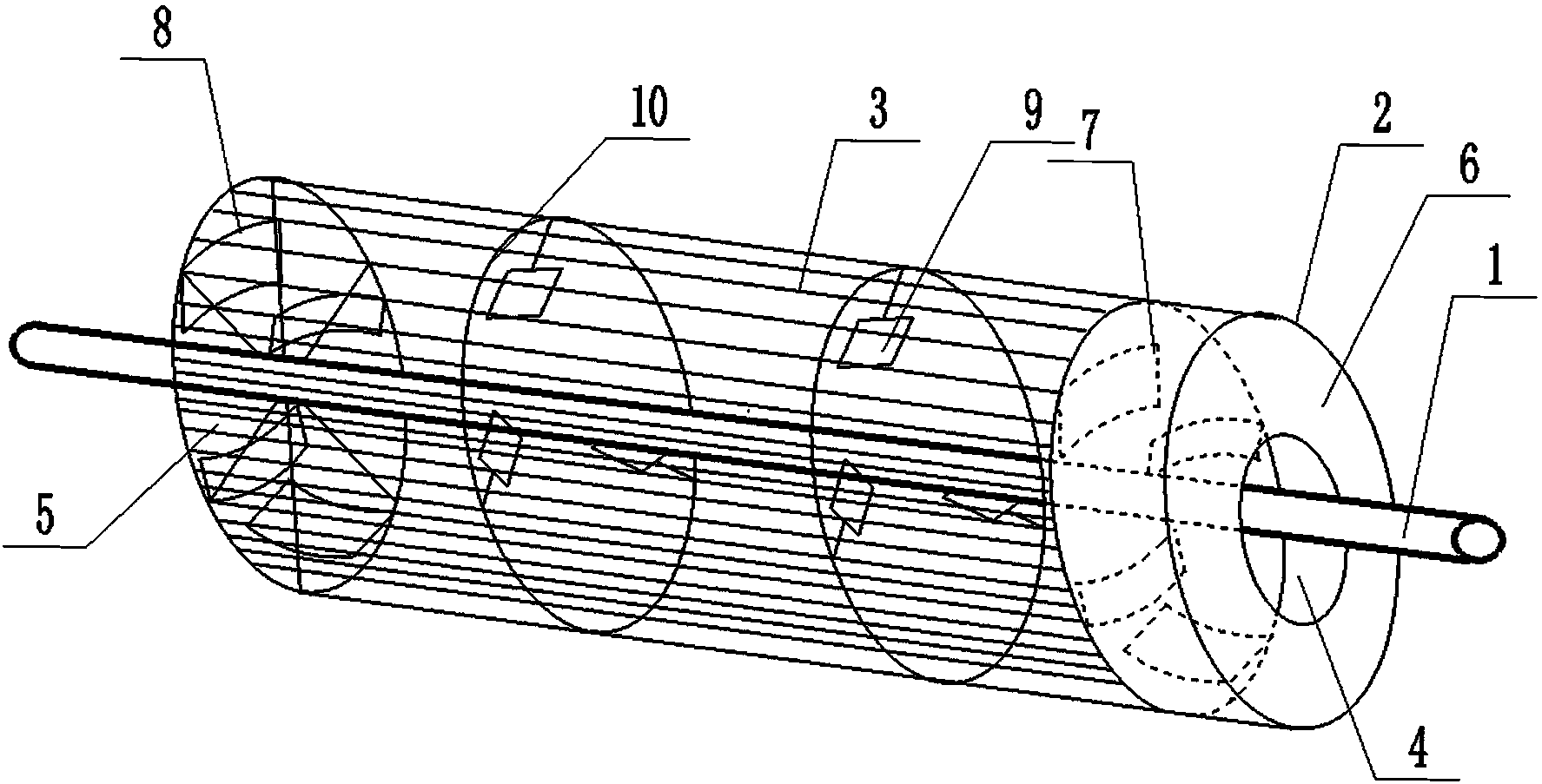

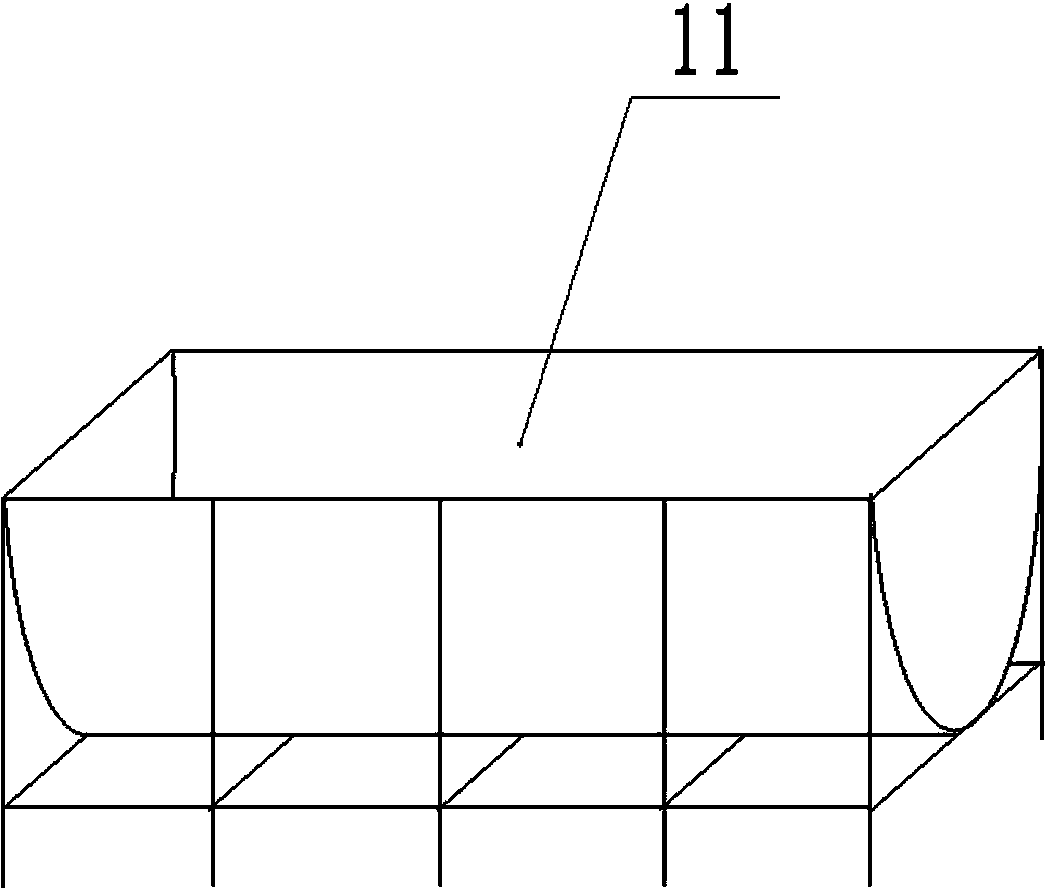

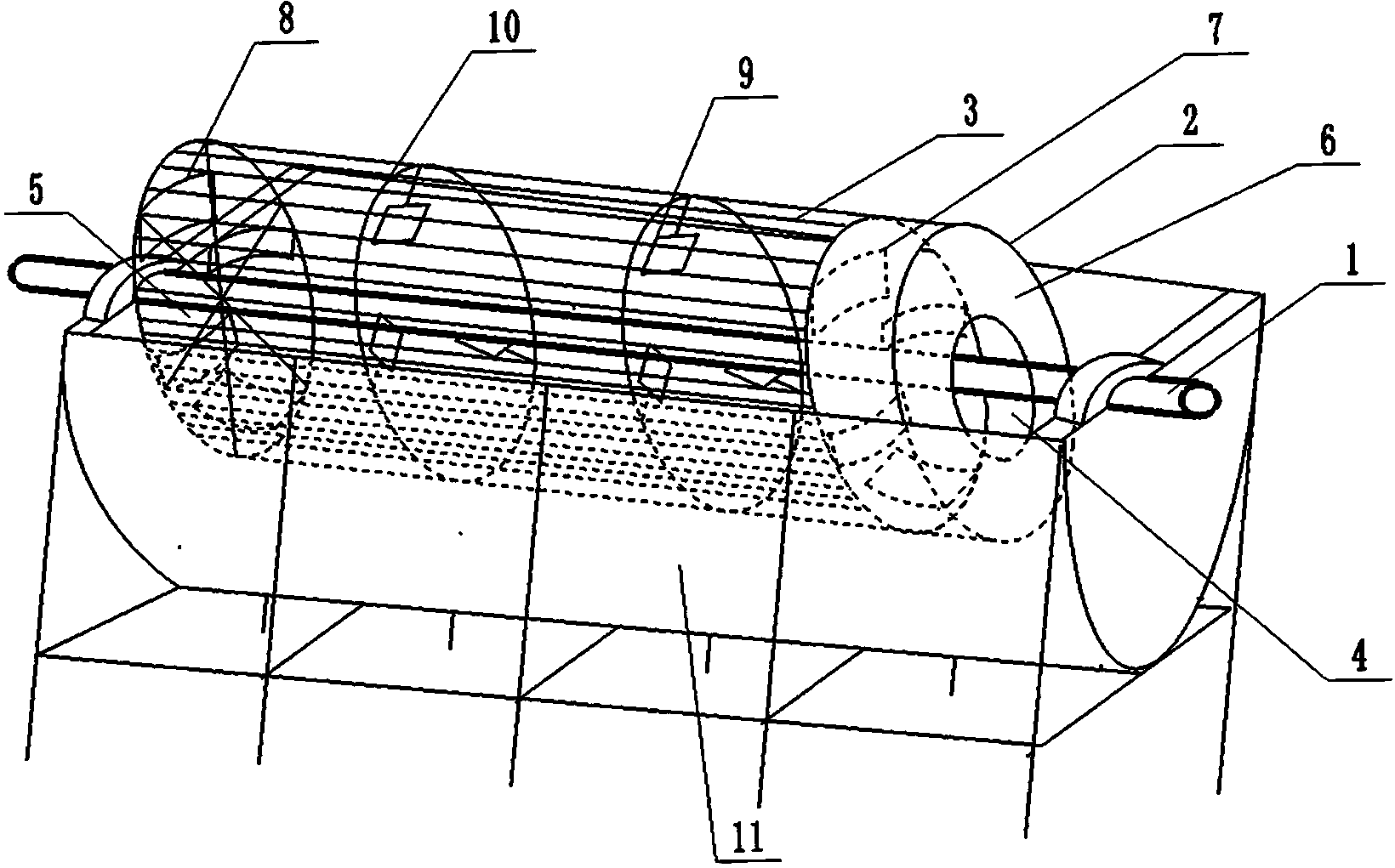

[0028] refer to Figure 1~Figure 4 . The horseshoe automatic continuous cleaning machine includes a horseshoe cleaning container. The horseshoe cleaning container is a drum 2 that can rotate around the central axis 1. The wall of the drum 2 is uniformly arranged ribs 3. One end of the drum 2 is provided with a feed port 4, and the other end of the drum 2 is provided. The discharge port 5 is provided with a feed port baffle 6 around the feed port 4, a feed plate 7 is provided at one end of the feed port 4 of the drum 2, a discharge plate 8 is provided at one end of the discharge port 5 of the drum 2, and a discharge plate 8 is provided at the middle section of the drum 2 Push plate 9. The ribs 3 of the drum 2 walls are spaced at 1.5cm, the ribs 3 are made of metal, and the ribs 3 are circular. An inlet stopper 6 is set at the feed port 4 to prevent the horseshoe from entering the feed port 4 and then exiting. Both the feed port 4 and the discharge port 5 are arranged around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com