Hilum cutting machine

A technology for umbilical cutting and umbilical cutting machine, applied in the field of umbilical cutting machine, can solve the problems of complicated machine maintenance and high manufacturing and use costs, and achieve the effects of simple structure, low manufacturing and use costs, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

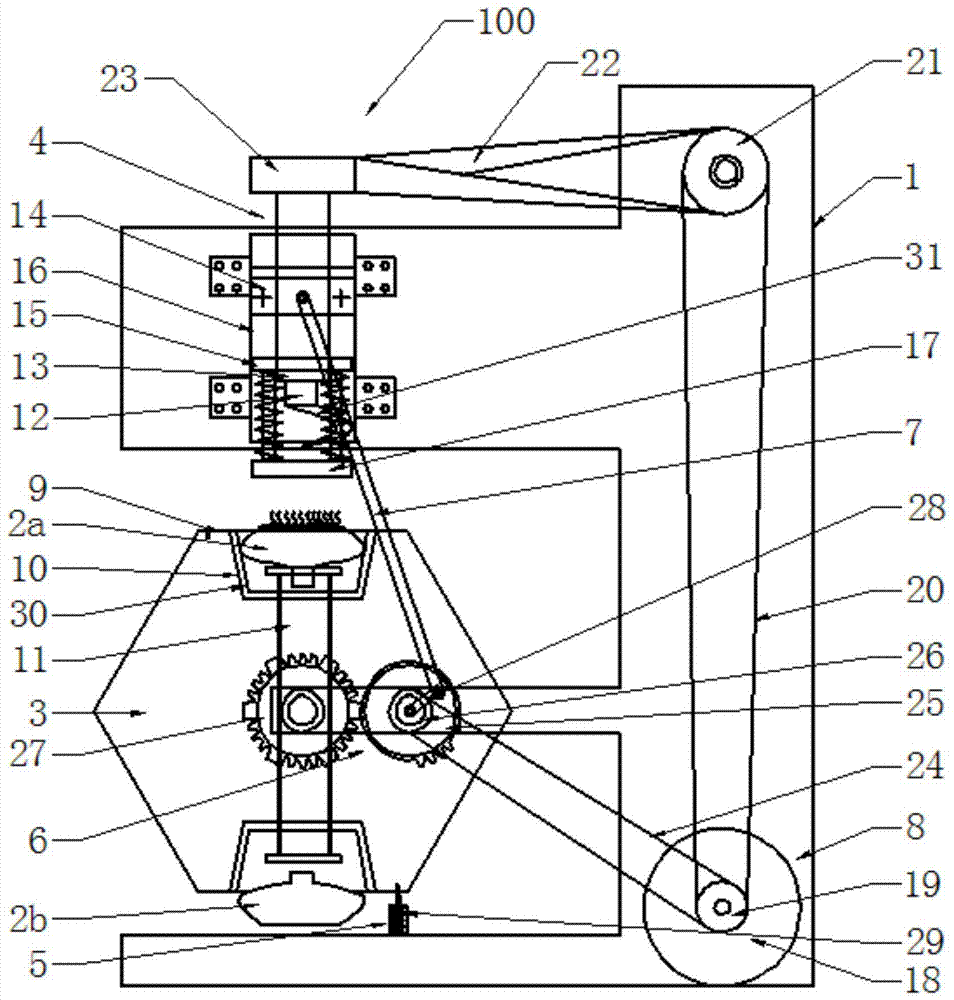

[0030] figure 1 It is a structural schematic diagram of a central cutting umbilical machine according to Embodiment 1 of the present invention.

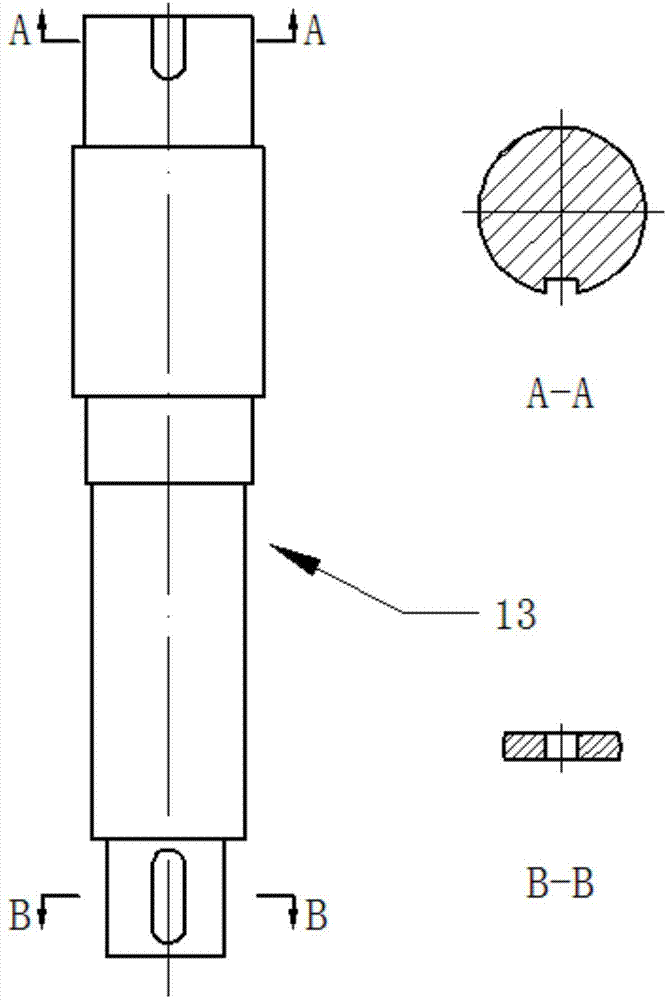

[0031] figure 2 for figure 1 Schematic diagram of the main shaft in the center cutting umbilical machine.

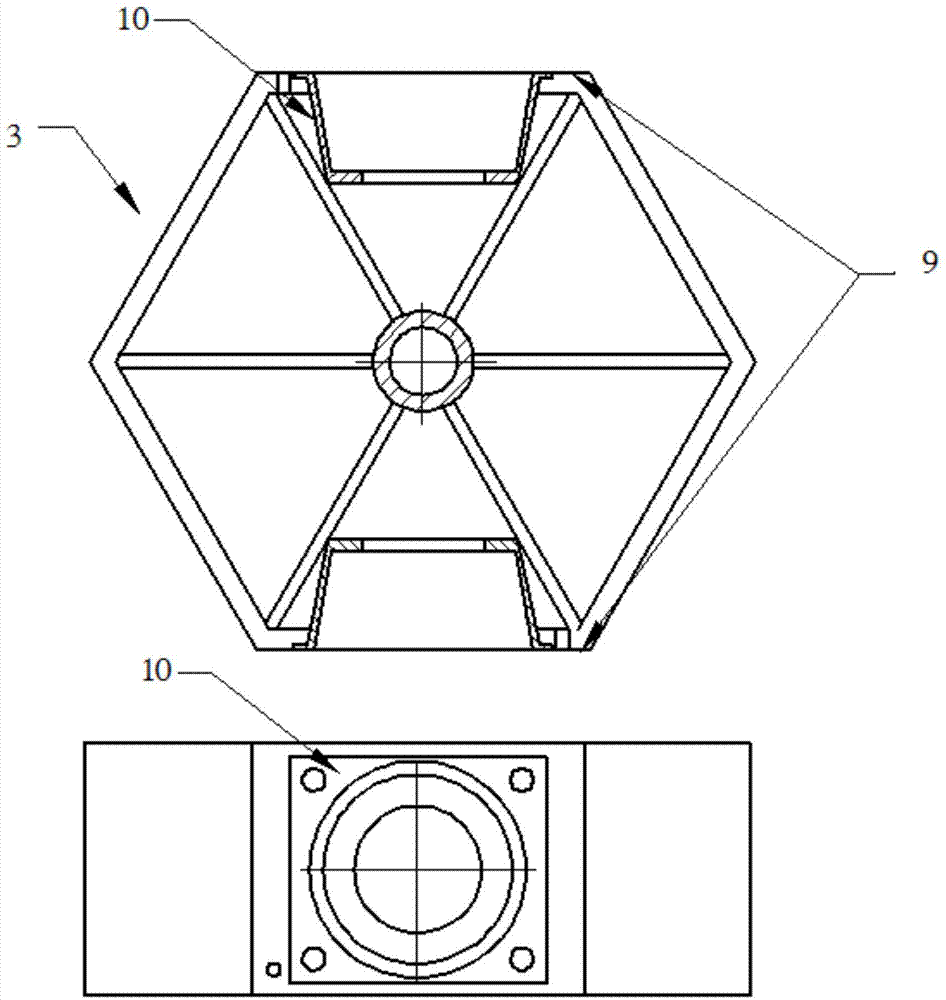

[0032] like figure 1 As shown, the umbilicus cutting machine 100 for removing the umbilical part of the umbilical item to be cut with the umbilical part in this embodiment includes a frame part 1; a rotary table 3 for carrying the umbilical item to be cut; On the frame part 1 and the cutting device 4 that is arranged opposite to the rotary table 3; the spring positioning pin 5 that is fixed on the frame part 1 for positioning the rotary table 3; is arranged on the frame part 1 for driving The gear pair 6 that the rotary table 3 rotates; the crank-link slider mechanism 7 that is installed on the gear pair 6 to drive the cutting device 4 to reciprocate toward the umbilical item to be cut; and simultaneously drives the gear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com