Household paper and preparation thereof

A technology for household paper and single-layer paper, applied in papermaking, papermaking machines, household appliances, etc., can solve the problems of yellowing, stubby, rough surface feel, etc., so as to reduce production costs, save wood resources, and increase surface smoothness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

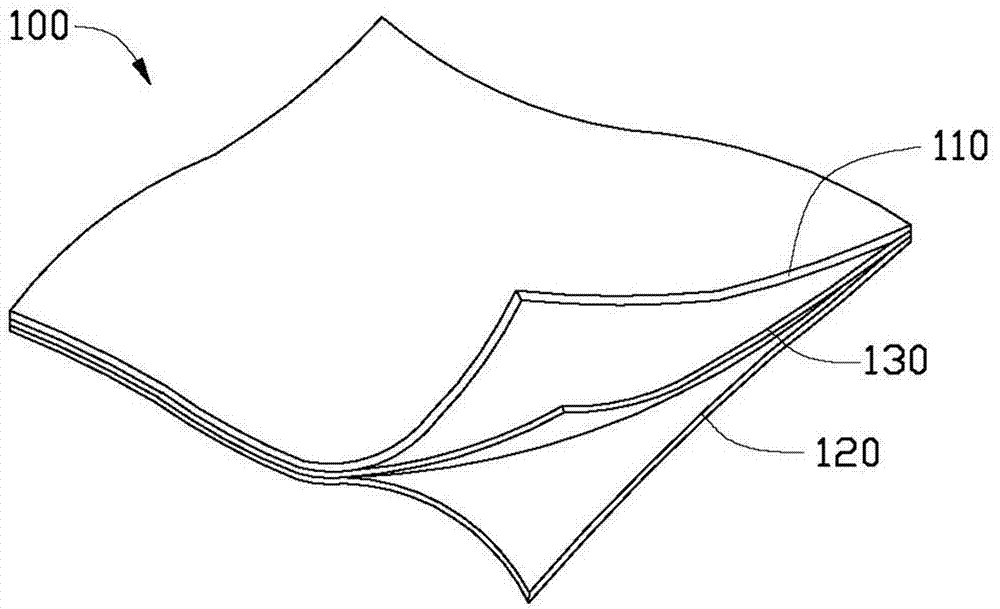

[0014] see figure 1 , the household paper 100 includes at least one layer of single-layer paper, the single-layer paper is composed of three layers of fiber layers stacked, one of the three layers of fiber layers is made of high The fiber layer formed by yield pulp has one layer of fiber layer formed by short fiber slurry, and one layer of fiber layer formed by long fiber slurry.

[0015] The three fiber layers include a first outer layer 110 , a second outer layer 120 and an intermediate layer 130 sandwiched between the first outer layer 110 and the second outer layer 120 . Preferably, the first outer layer 110 is a fiber layer formed from filled high-yield pulp, the second outer layer 120 is a fiber layer formed from short fiber pulp, and the middle layer 130 is formed from long fiber pulp Formed fiber layers.

[0016] It can be understood that, in other embodiments, the household paper can also be composed of four or more fiber layers, at least one layer is a fiber layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com