High Efficiency Crystallizer for Continuous Casting Machine

A mold and casting machine technology, applied in the field of high-efficiency molds for continuous casting machines, can solve problems such as uneven cooling of molds, and achieve the effects of improving appearance quality, improving internal quality, and uniform cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

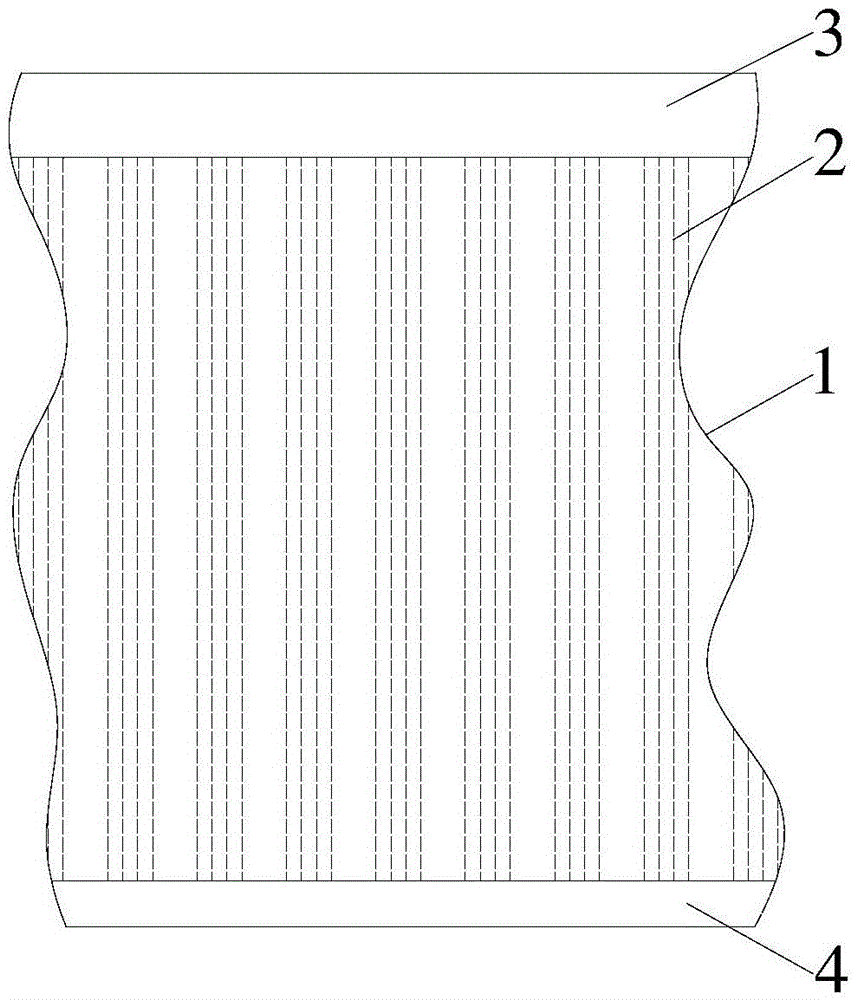

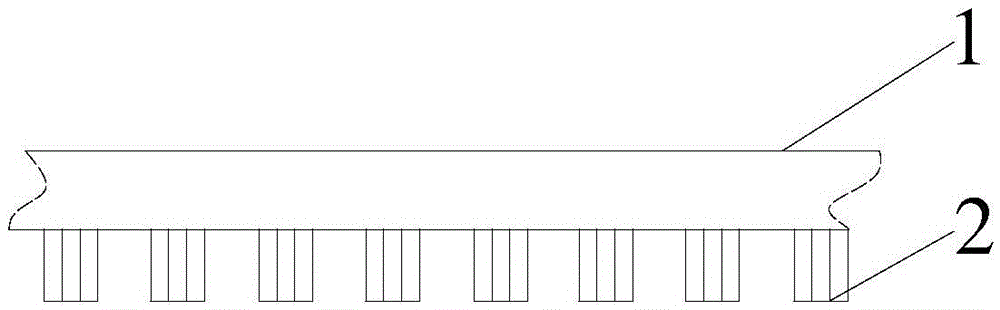

[0024] Such as figure 1 , figure 2 As shown, a high-efficiency crystallizer for a continuous casting machine includes a slab copper tube crystallizer wall 1 and straight fins 2, the fins 2 are evenly distributed outside the crystallizer wall 1, and the distance between the fins 2 The fins 2 and the crystallizer tube wall 1 form an upper cavity 3 and a lower cavity 4. The upper cavity 3 and the lower cavity 4 are respectively located at the upper and lower ends of the crystallizer tube wall 1. The height of the upper cavity 3 is 80mm, the height of the lower cavity 4 is 54mm.

Embodiment 2

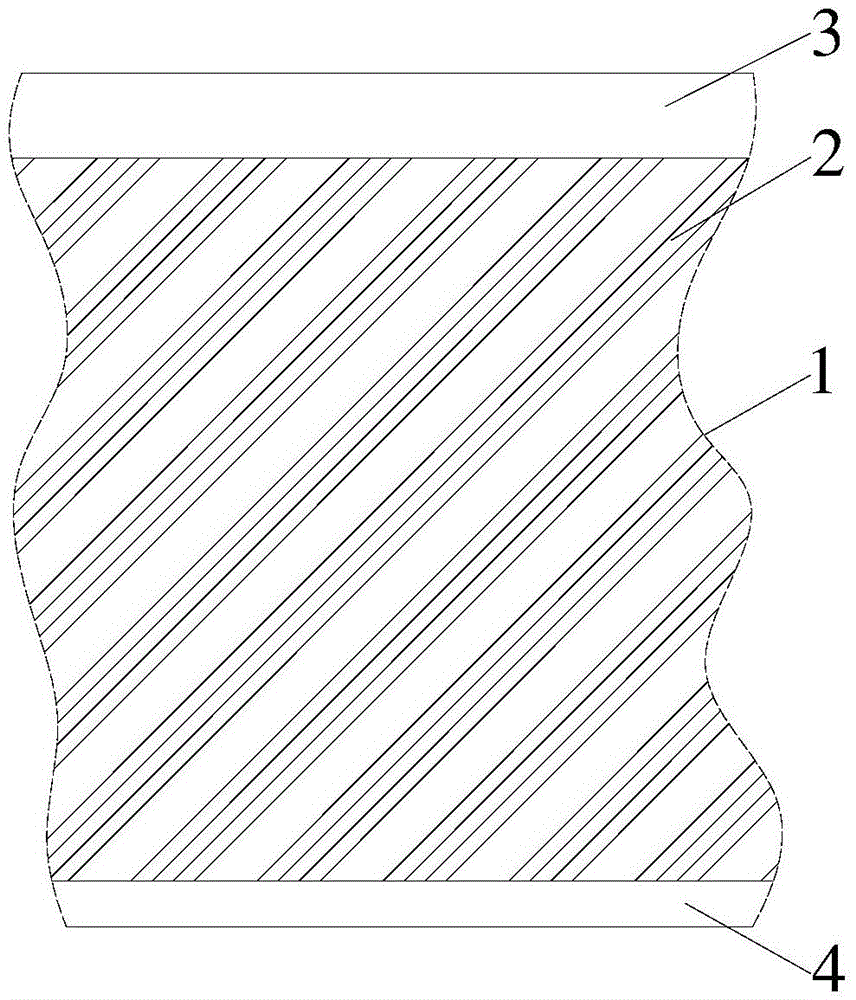

[0026] Such as image 3 , Figure 4 As shown, a high-efficiency crystallizer for a continuous casting machine includes a round billet copper tube crystallizer tube wall 1 and trapezoidal fins 2, and the fins 2 are evenly screwed outside the crystallizer tube wall, and the distance between the fins 2 is 5mm, the fins 2 and the crystallizer tube wall 1 form an upper cavity 3 and a lower cavity 4, the upper cavity 3 and the lower cavity 4 are respectively located at the upper and lower ends of the crystallizer tube wall 1, and the height of the upper cavity 3 is 50mm, the height of the lower cavity 4 is 40mm.

Embodiment 3

[0028] Such as Figure 5 , Figure 6 As shown, a high-efficiency crystallizer for a continuous casting machine includes an annular mold tube wall 1 and an annular fin 2, the distance between the fins 2 is 7 mm, and the fins 2 and the crystallizer tube wall 1 form an upper cavity 3 And the lower cavity 4, the upper cavity 3 and the lower cavity 4 are respectively located at the upper and lower ends of the crystallizer tube wall 1, the height of the upper cavity 3 is 80mm, and the height of the lower cavity 4 is 60mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com