Forged golf club head manufacturing method

A technology for golf club heads and manufacturing methods, which is applied to golf balls, golf clubs, rackets, etc., can solve problems such as inaccurate shapes, welding marks, time-consuming and labor-intensive processing, etc., so as to reduce working time, reduce working time, Ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

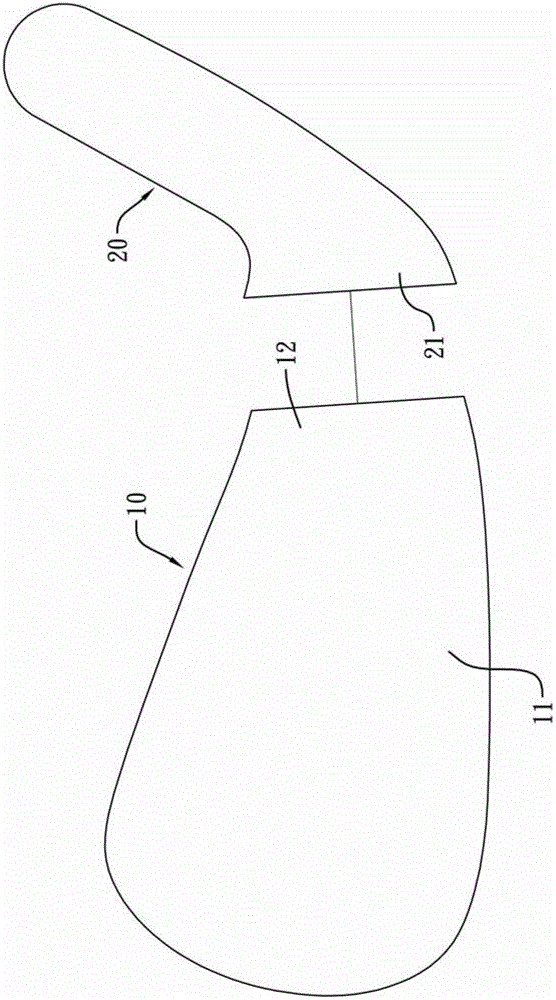

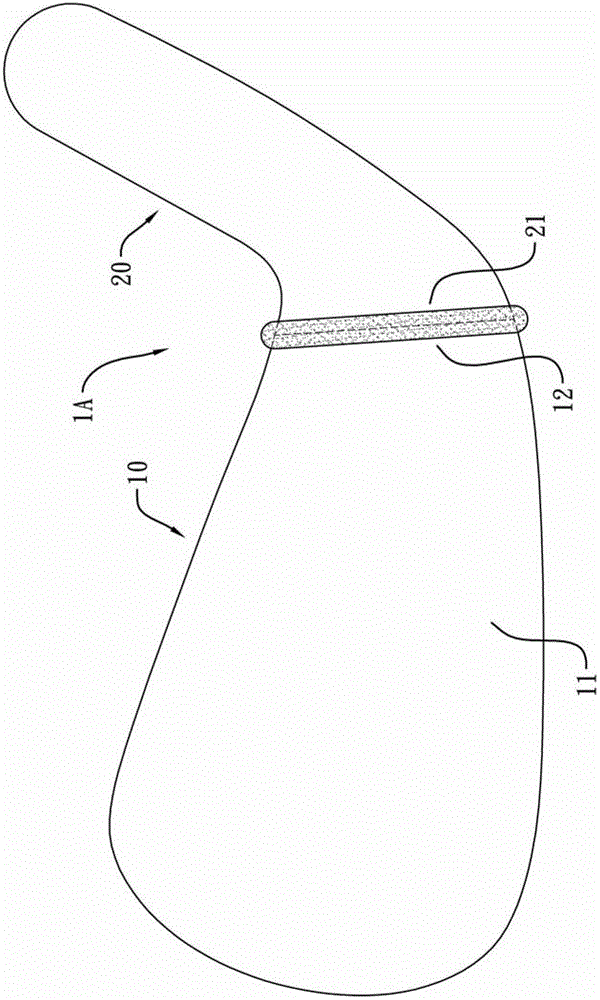

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

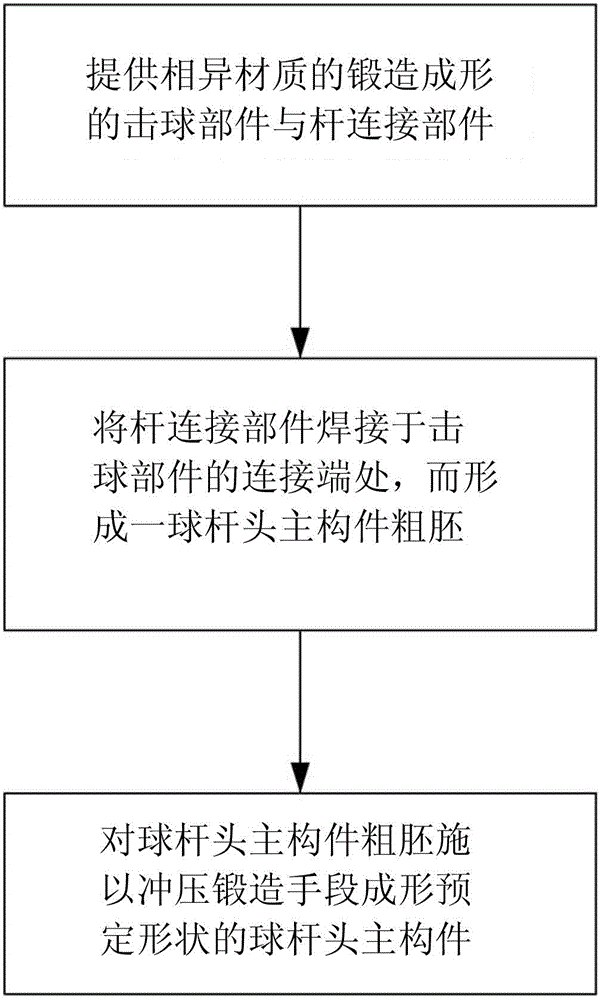

[0039] Such as figure 1 and Figure 5 Shown is a flow chart disclosing several preferred embodiments of the manufacturing method of the forged golf club head of the present invention. It can be seen from these flow charts that the manufacturing method of the forged golf club head mainly includes the following implementation steps:

[0040] Provide a pre-forged ball hitting part and a rod connection part, the ball hitting part and the rod connecting part are parts of different materials, the ball hitting part includes a ball hitting surface and a connecting end located at one end of the ball hitting surface, so The material of the ball-hitting part is selected from high-strength, high-hardness and high-elastic metal material, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com