A high-efficiency and energy-saving spray can capping system

A high-efficiency, energy-saving, spray can technology, which is applied to conveyor objects, transportation and packaging, packaging, etc., can solve the problems of limited physical strength, insufficient energy saving, and high energy consumption of operators, so as to avoid harm to the human body, ensure completion efficiency, The effect of shortening the conveyor line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

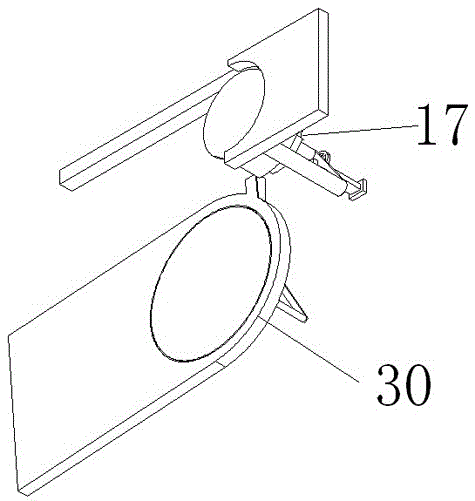

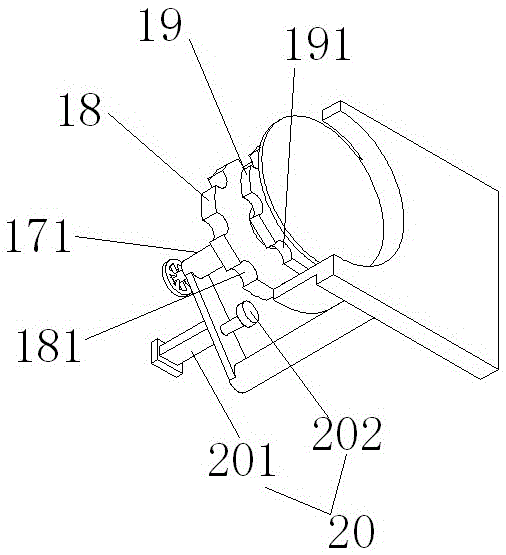

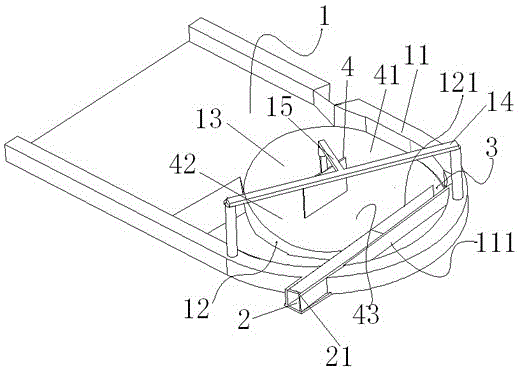

[0029] A high-efficiency and energy-saving spray can capping system provided by the present invention, as attached figure 1 Shown: comprise can lid transmission device 30 and add cap device 17; Described add cap device 17 comprises rotating shaft 171, the upper rotating disc 18 that is fixed on the rotating shaft 171, the lower rotating disc 19 that is fixed on the rotating shaft 171 and is used for aerosol can The body and the tank cover are pressed together, and the top of the rotating shaft 171 is provided with a hand wheel. When the material is stuck or malfunctions, it can be manually rotated, and the angle can be adjusted as required for maintenance. The pressing device 20 includes a vertical pressing cylinder 201, the piston rod of the vertical pressing cylinder 201 is screwed with a pressure head 202, the lower surface of the pressure head 202 is circular, and the diameter of the circle is 0.9-1.1 times the outer diameter of the can lid, so that the force of the gland ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com