Method of continuously purifying potassium nitrate in batch in waste generated by glass hardening process

A technology of glass hardening and potassium nitrate, applied in the field of purification of potassium nitrate, which can solve the problems of waste, high manufacturing cost, and the melt can no longer undergo ion exchange reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0021] The applicant first explains here that the term "approximate" mentioned throughout the specification means "may be higher or lower".

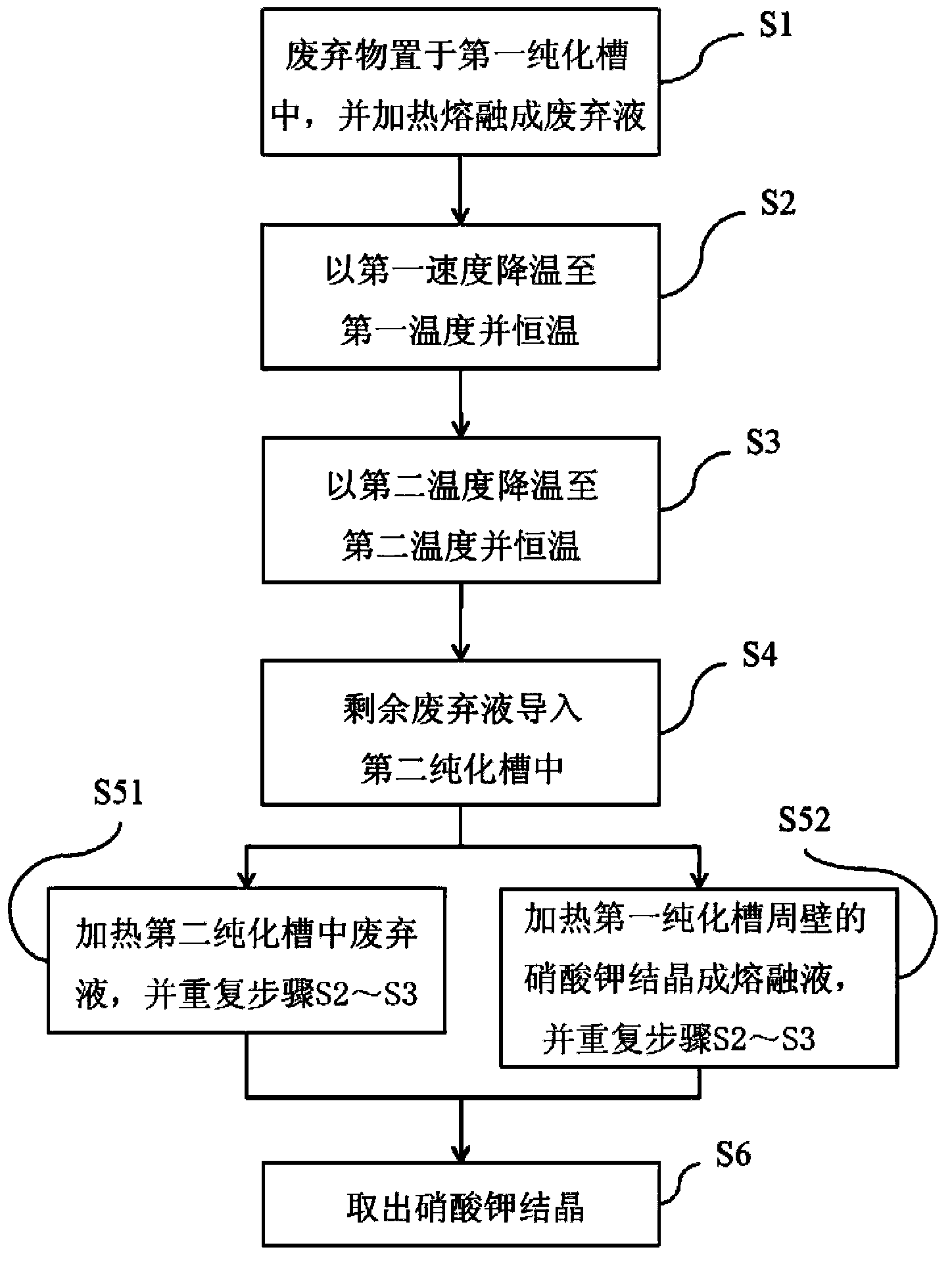

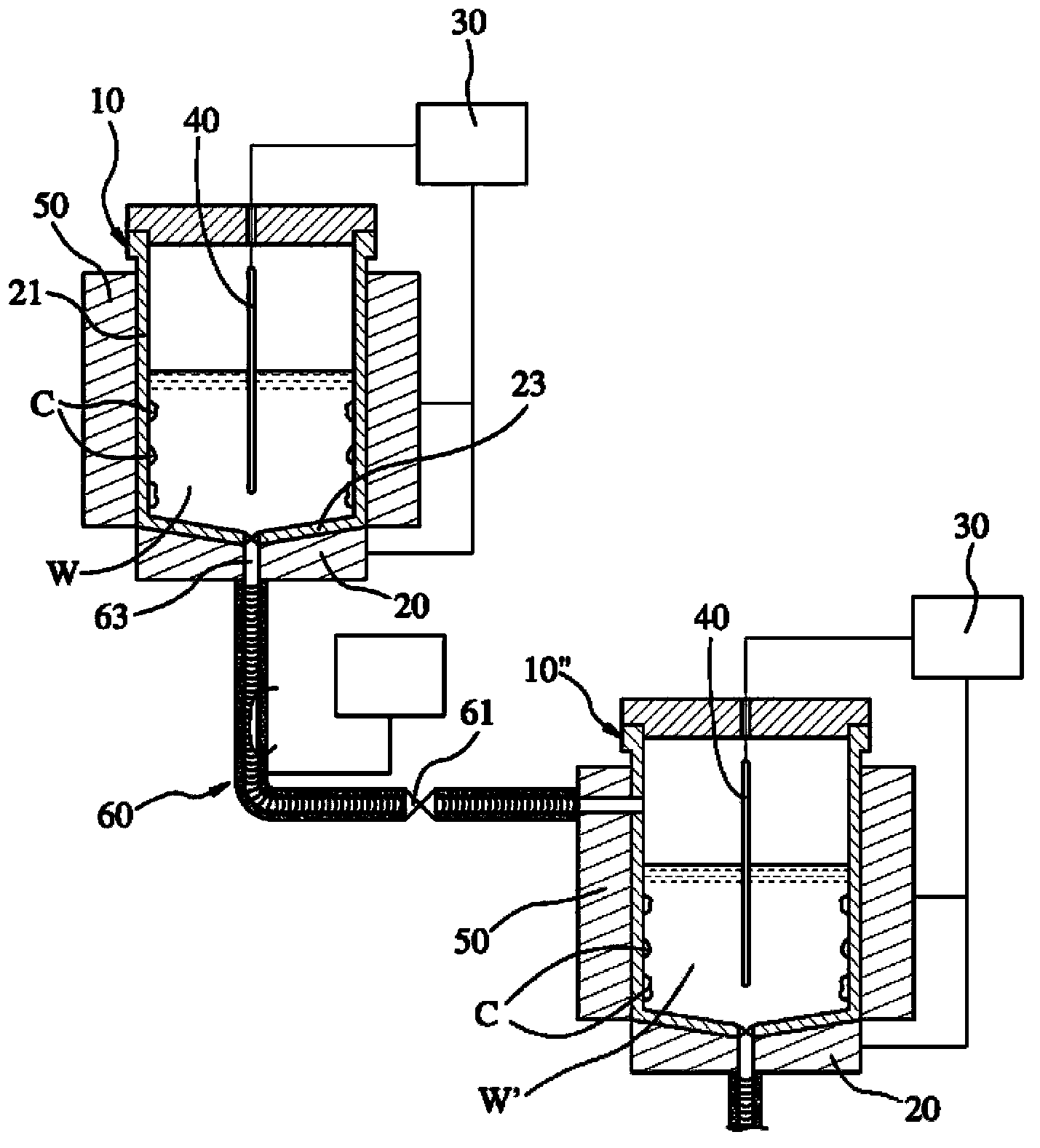

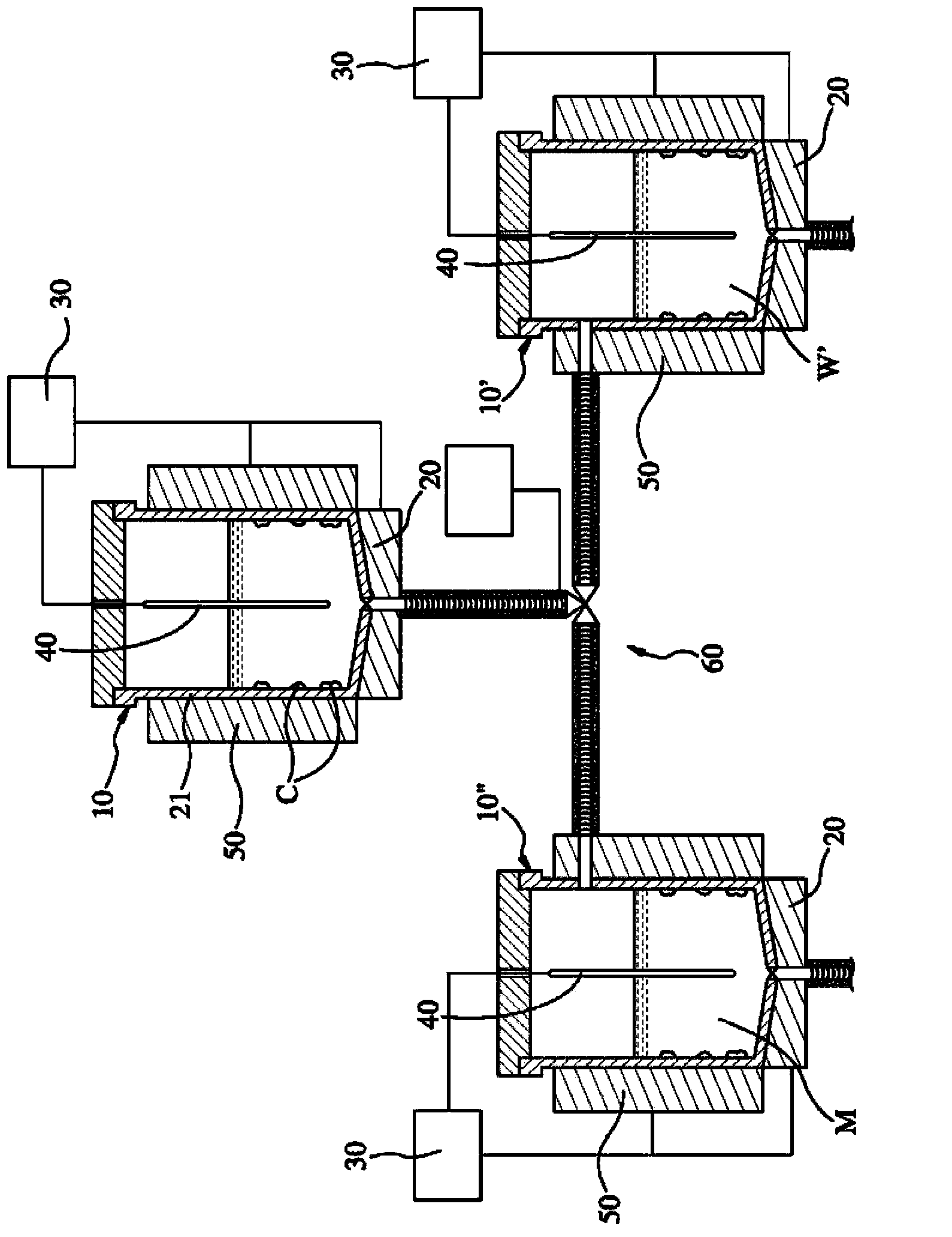

[0022] First, if figure 1 , figure 2 As shown, in a preferred embodiment provided by the present invention, in step S1, first the glass hardening process produced contains potassium nitrate (potassium nitrate, KNO 3 ) and sodium nitrate (sodium nitrate, NaNO 3 ) solid waste into a first purification tank 10, and then heated to a melting temperature of about 380°C to 550°C with a heater 20 arranged at the bottom 23 of the first purification tank 10, and allowed to stand at this temperature For a period of time, such as about 1 to 10 hours, the waste is completely melted into a waste liquid W. In this example, by setting a default temperature for a temperature control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com