Fluidized bed reactor applied to adsorption desulfurization and application thereof

A fluidized bed reactor, adsorption desulfurization technology, applied in the petroleum industry, refined hydrocarbon oil and other directions, can solve the problems of the filter influence still exists, catalyst dust residue and other problems, achieve low backflushing frequency, ensure the filtering effect, stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

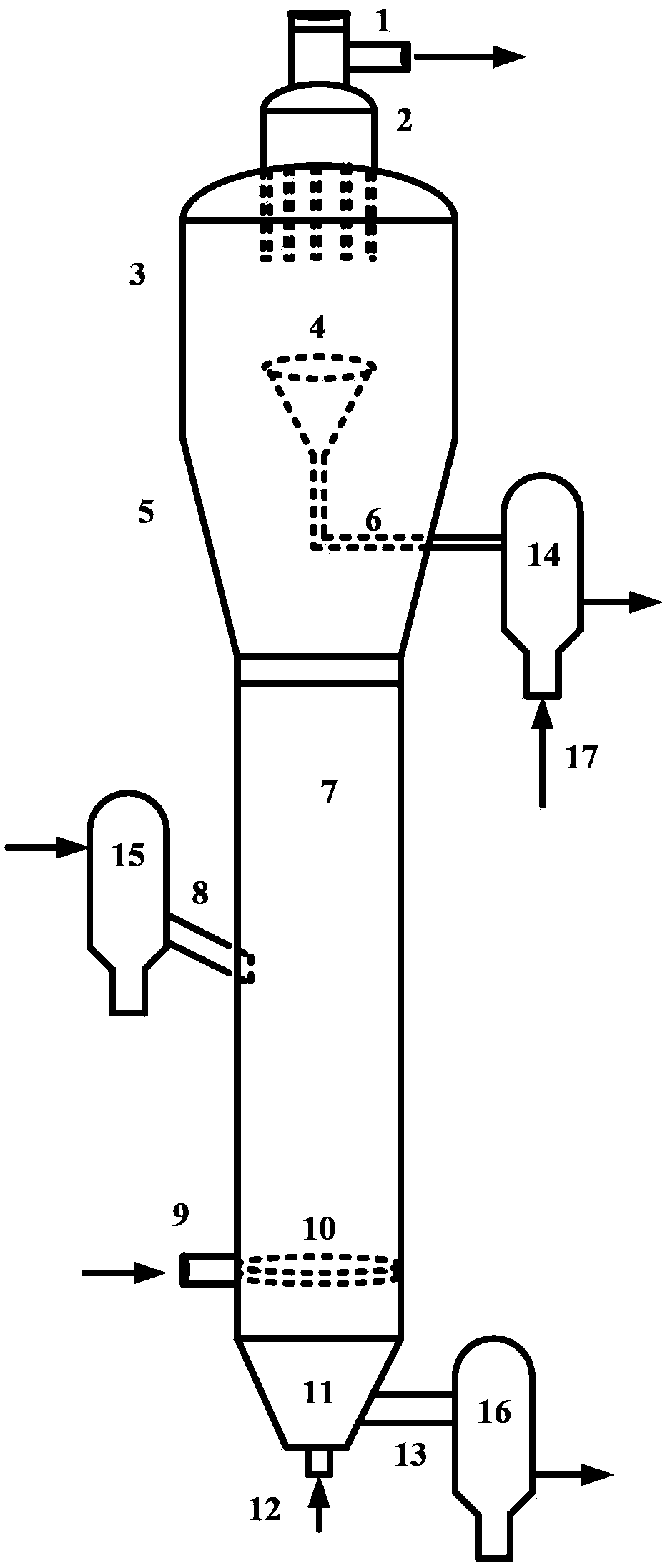

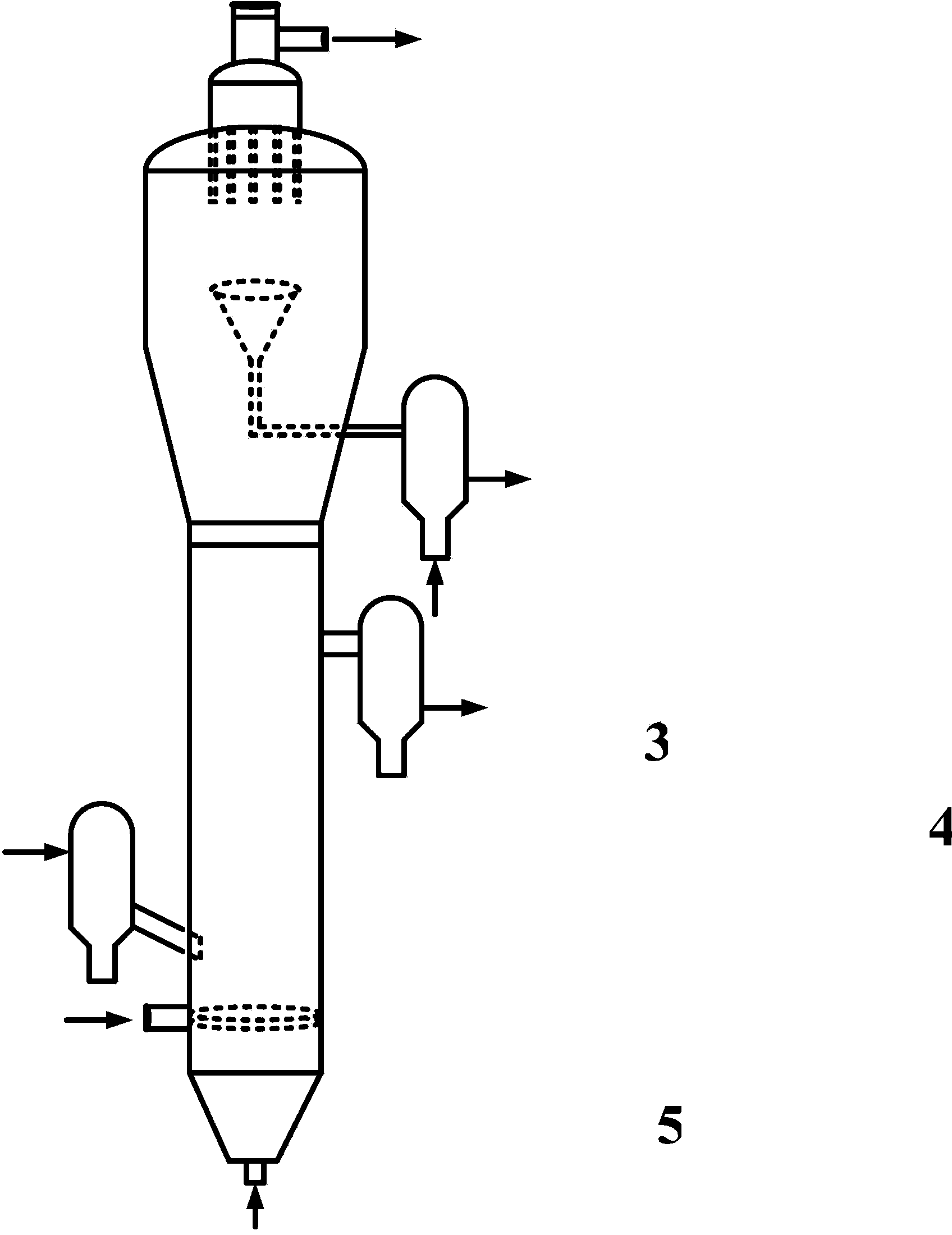

[0015] Fluidized bed reactor provided by the invention is implemented like this:

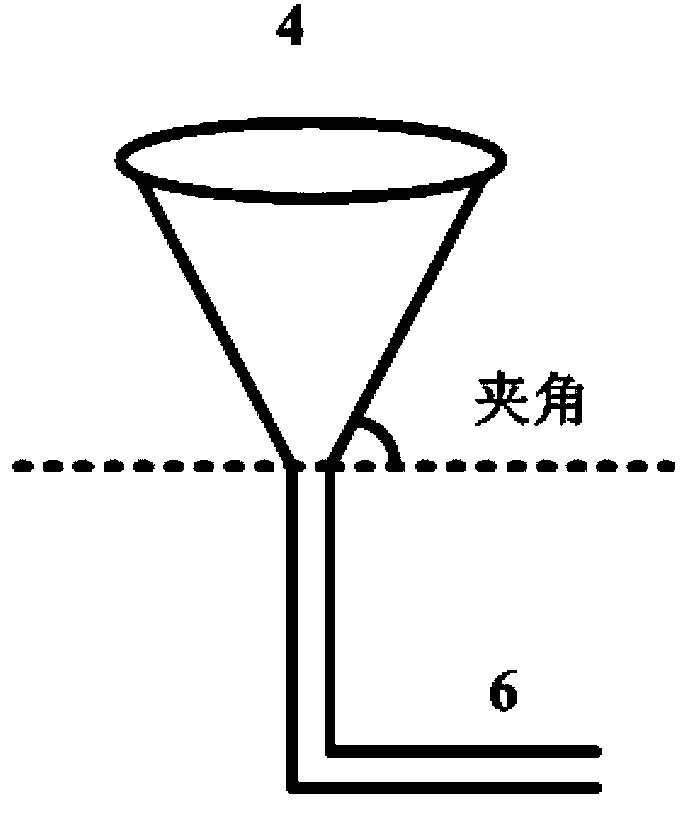

[0016] A fluidized bed reactor for adsorption desulfurization, comprising from bottom to top: a reaction section 7, a settling section 5 with enlarged pipe diameter, and a separation section 3. The reaction section 7 is provided with an adsorbent inlet, a reaction oil gas inlet, Gas inlet and standby adsorbent outlet, the top of the separation section 3 is provided with a gas-solid separation device 2, and the top of the gas-solid separation device is an oil gas outlet 1. A dust collection hopper 4 is arranged in the separation section 3 .

[0017] In the fluidized bed reactor provided by the present invention, the reaction section 7 is externally connected with a reducer 15, and the reducer 15 is connected to the adsorbent inlet on the reaction section through the reducer inclined tube 8. After the regenerated adsorbent is reduced in the reducer 15, it enters the reaction section 7 through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com