Reinforced concrete frame joint area plus steel plate and steel wire mesh wrapped reinforcement structure and preparation method

A technology of reinforced concrete and reinforced concrete columns, which is applied to structural elements, building reinforcements, building components, etc., can solve problems such as structural collapse, failure to achieve the design goals of strong columns and weak beams, and failure to consider the multi-dimensionality of ground motion input. Prevent early fall off, bear reasonable force, and strengthen the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

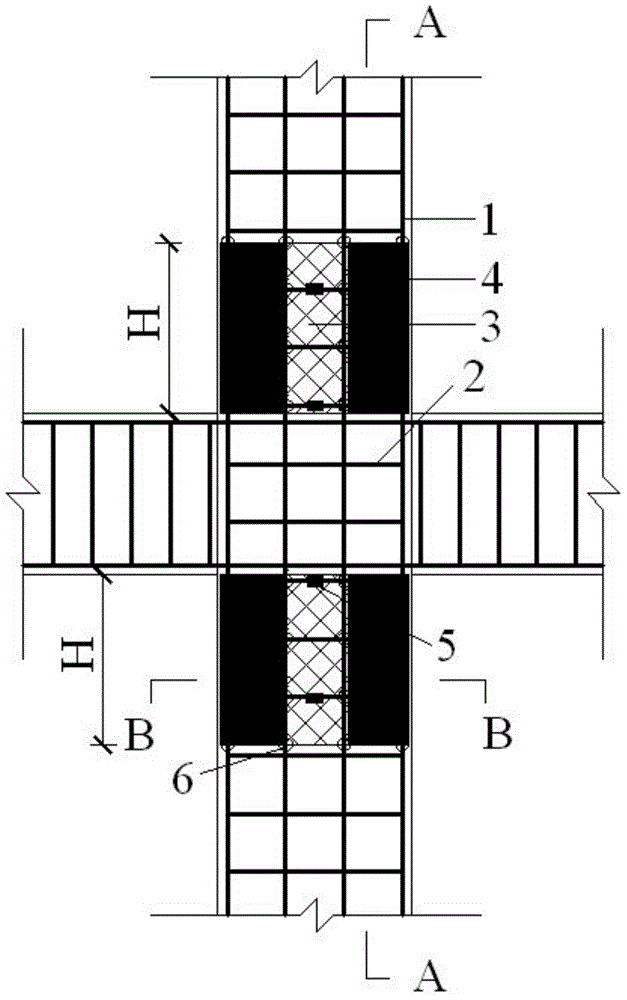

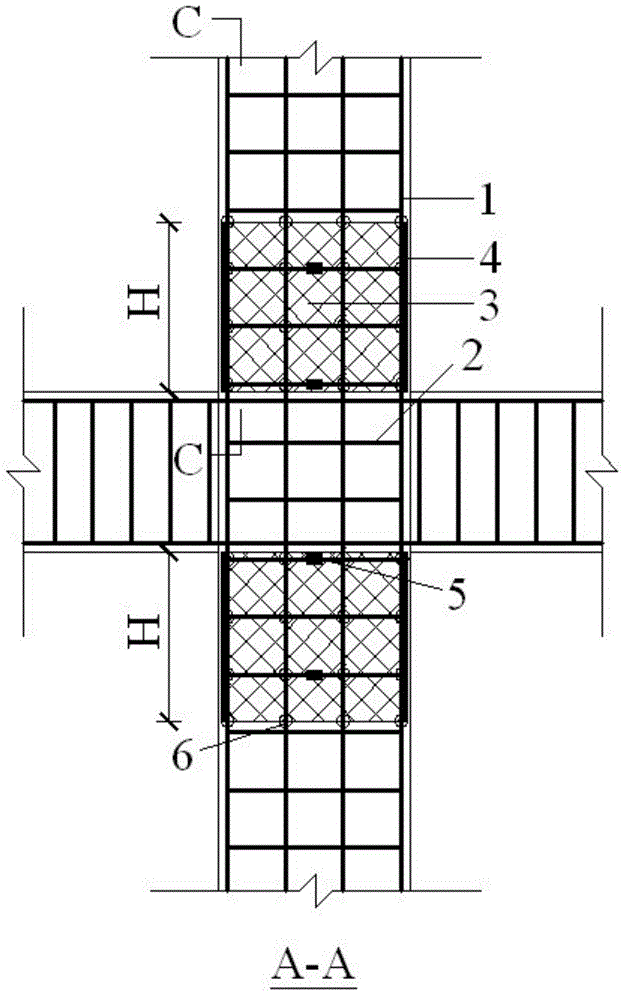

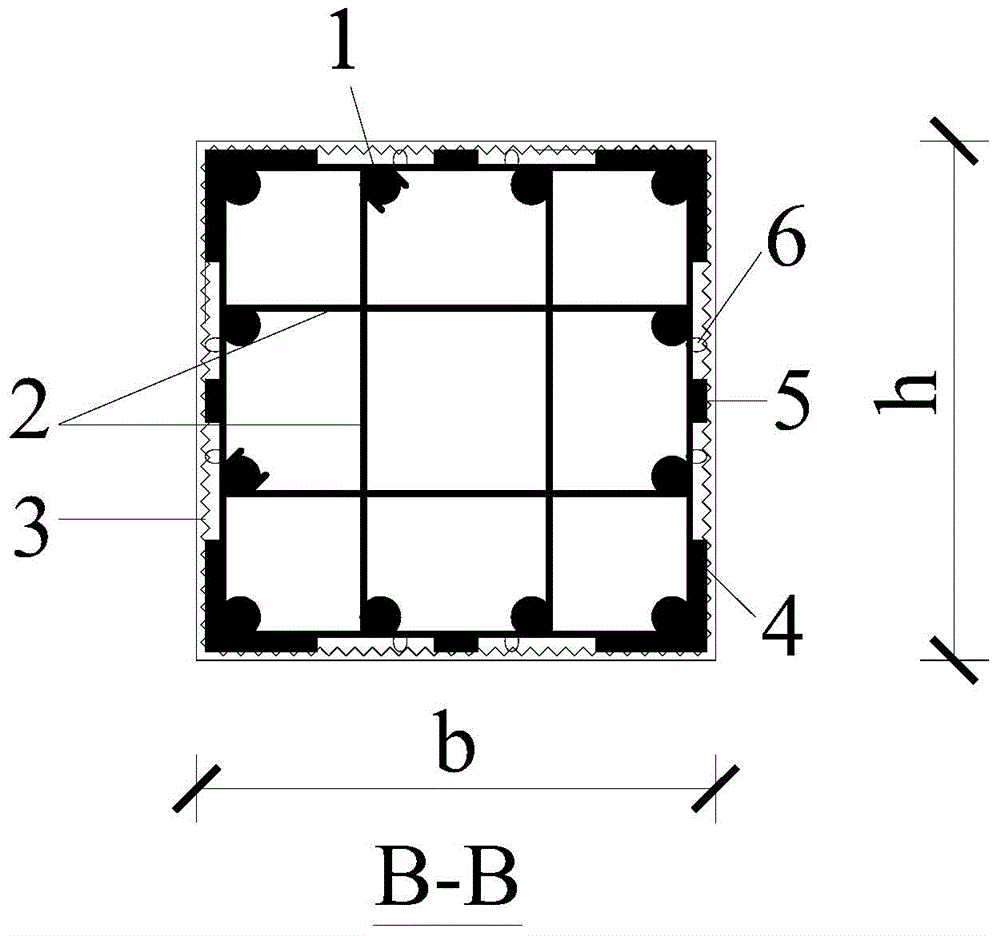

[0029] A reinforcement structure wrapped with steel plates and steel wire mesh in the node area of a reinforced concrete frame, including a reinforcement cage, which is formed by binding and fixing the longitudinal bars 1 and stirrups 2 of a reinforced concrete column; The net 3, the L-shaped steel plate 4, the spacer block 5 and the binding wire 6; the reinforced structure refers to: in the beam-column node area, the upper and lower corners of the column node are partially covered with L-shaped steel plates 4, L The height of the shaped steel plate along the direction of the column height is H, H takes the larger value of 1.5h and 500mm, h is the cross-sectional height of the reinforced concrete column; for the upper part of the column joint, the lower edge of the L-shaped steel plate and the middle beam section of the frame joint The upper edge coincides; for the lower part of the column joint, the upper edge of the L-shaped steel plate coincides with the lower edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com